Flat crush test (FCT) on corrugated board | ISO 3035

Corrugated board transport containers may be exposed to compression forces acting on the wall thickness during manufacture as well as compression forces during transport or storage. These compression forces can compress the corrugated structure and reduce the stability of the corrugated board during stacking. Resistance to this type of pressure is an important measure of the characteristic performance of a transport container. The ISO 3035 and Tappi T825 standards describe the flat crush test (FCT)used to determine the flat crush resistance of corrugated board used in the manufacture of corrugated board transport containers.

In the flat crush test, a single-flute corrugated board with a horizontal flute orientation is subjected to compressive load perpendicular to its surface until it collapses. The result is the FCT value in kN/m², i.e., the resistance that the corrugated board counters. The specimen usually has an area of 100 or alternatively 50 cm². The FCT is used to characterize the strength of corrugated board. The FCT cannot be performed on multi-wall corrugated board. The reason for this is that the middle layers can deviate and would falsify the result.

ISO 7263 (CMT) describes how to determine the flat crush resistance of corrugated paper, which is used to produce corrugated board.

Characteristic curve Test equipment requirements Related materials testing machines Downloads Request a consultation

Flat crush test (FCT) with ZwickRoell

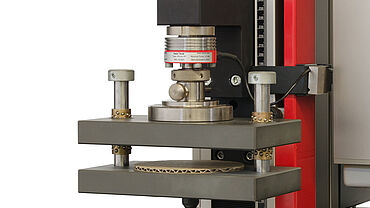

- The same precision-guided ZwickRoell compression platens with excellent lateral stiffness are used for the flat crush test as for the edge crush test (ECT) to ISO 3037. This means that distorted flutes, as shown in the picture, are a thing of the past. As the flute height decreases, FCT values increase.

- Modern miniature flutes tend to collapse only under forces greater than 10 kN, requiring extremely high lateral stiffness in the compression platens. Therefore, when determining the FCT on microflute corrugated boards, particular attention must be paid to the lateral stiffness of the test device. For these cases, ZwickRoell offers extremely stiff compression platens designed for vertical forces up to 250 kN.

- The zwickiLine is a suitable materials testing machine for grades up to 500 kPa. Two-column material testing machines

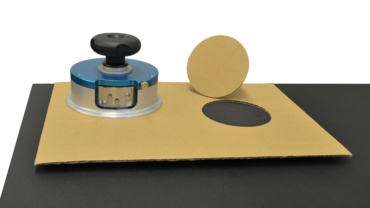

such as the ProLine or AllroundLine can also be considered. - A circular cutter is used to ensure accurate specimen preparation.

Characteristic Curve

- Depending on individual flute heights, the highest flutes collapse first, then the middle ones, followed by the remaining flutes at the end of the test.

- The crush energy and curve provide indications of the level of any predamage which may be present, since the curve is fundamentally different if the cardboard has been subjected to predamage.

More tests for corrugated board packaging, corrugated board, and corrugated base paper

| Short description | Standards |

|---|---|

| Paper, cardboard & corrugated board | burst test |

|

| Paper | Corrugated paper | Corrugating medium test (CMT) |

|

| Paper & cardboard | Compressive strength / short clamping test (SCT) |

|

| Paper, cardboard & corrugated board | Flexure test / stiffness under flexure (2-point, 3-point, 4-point) |

|

| Paper | Corrugated paper | Short-span compressive strength (S-test) |

|

| Cardboard | corrugated board | Flexure test / Quality of creasings |

|

| Cardboard | Corrugated board | Puncture test (LPET vs. PET) |

|

| Cardboard | Corrugated board | Flat crush test (FCT) |

|

| Cardboard | Corrugated board | Edge crush resistance (ECT) |

|

| Cardboard | Corrugated board | Box compression test / stacking test (BCT) |

|