Burst Test

ISO 2758, ISO 2759

The burst test determines the maximum resistance (in kPa) of a specimen to an increasing pressure. ZwickRoell burst testers determine the bursting strength of paper in accordance with ISO 2758. The bursting strength of board and paper to ISO 2759 can also be determined with ZwickRoell, thereby covering the entire range from paper to heavy corrugated board.

The Burst Test Explained

- To measure bursting strength the specimen is gripped securely between two clamping rings. Once a corrugated board specimen is clamped it is essential to maintain the gripping force to ensure reproducible test results.

- Particular attention must be paid to the dynamics of the testing equipment. As a burst test is performed within a few seconds and the maximum pressure must be determined with absolute precision, the measurement speed of the testing instruments must be correspondingly high.

- If results are to be compared between different laboratories, the measurement speeds of the instruments must be identical. A constant volume flow must also be maintained during the test with a high degree of accuracy.

Burst test with ZwickRoell ISO 2758, ISO 2759

Function description:

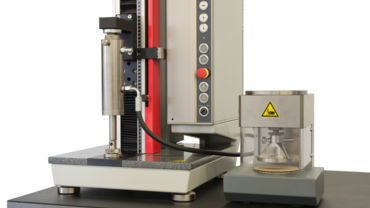

- The test fixture for determining the burst strength to ISO 2758 and ISO 2759 consists of a hydraulic actuator and a burst device.

- The hydraulic actuator is used to generate pressure. It is mounted in the testing system. The volume flow can be steplessly adjusted by changing the crosshead speed. The hydraulic actuator is connected to the burst device via a high pressure hose. Pressure is measured electronically using a strain gauge sensor.

- A pneumatic actuator is integrated in the burst device. It is used to clamp the specimen between the compression platen and the pressure chamber. The moving crosshead presses against the hydraulic actuator during the test, whereby a volume of liquid is pressed into the pressure chamber. The resulting, increasing pressure causes the rubber membrane to arch. The rubber membrane then presses against the specimen until it breaks.

Benefits:

- Burst tests with ZwickRoell materials testing machines are program-controlled, ensuring correct results at all times with a minimum of manual operator intervention.

- ZwickRoell offers a pressure pre-selector, which allows rapid selection of up to five different controlled gripping pressures via a rotary switch.

- The machine detects bursting of the specimen and stops immediately. This reduces the load on the diaphragm, extending its life.

- Tests are performed under constant conditions, even when there is a change in operator.

- The flow is controlled within a very narrow tolerance range and remains constant even at high loading.

- ZwickRoell materials testing machines employ digital control to ensure a constant volume flow regardless of load.

- Real-time graphics enable the operator to see immediately if the test has been performed correctly.

- Variable data acquisition rate guarantees consistent results between producer and processor, avoiding systematic discrepancies between different laboratories.

- Service interfaces and maintenance-friendly design reduce downtime and associated costs.