- MFR

- MVR

- Multi-stage test

- High

- 24/7 operation in QA

- Flexible in F&E

- Method A

- Method B

- Method C

- Method D

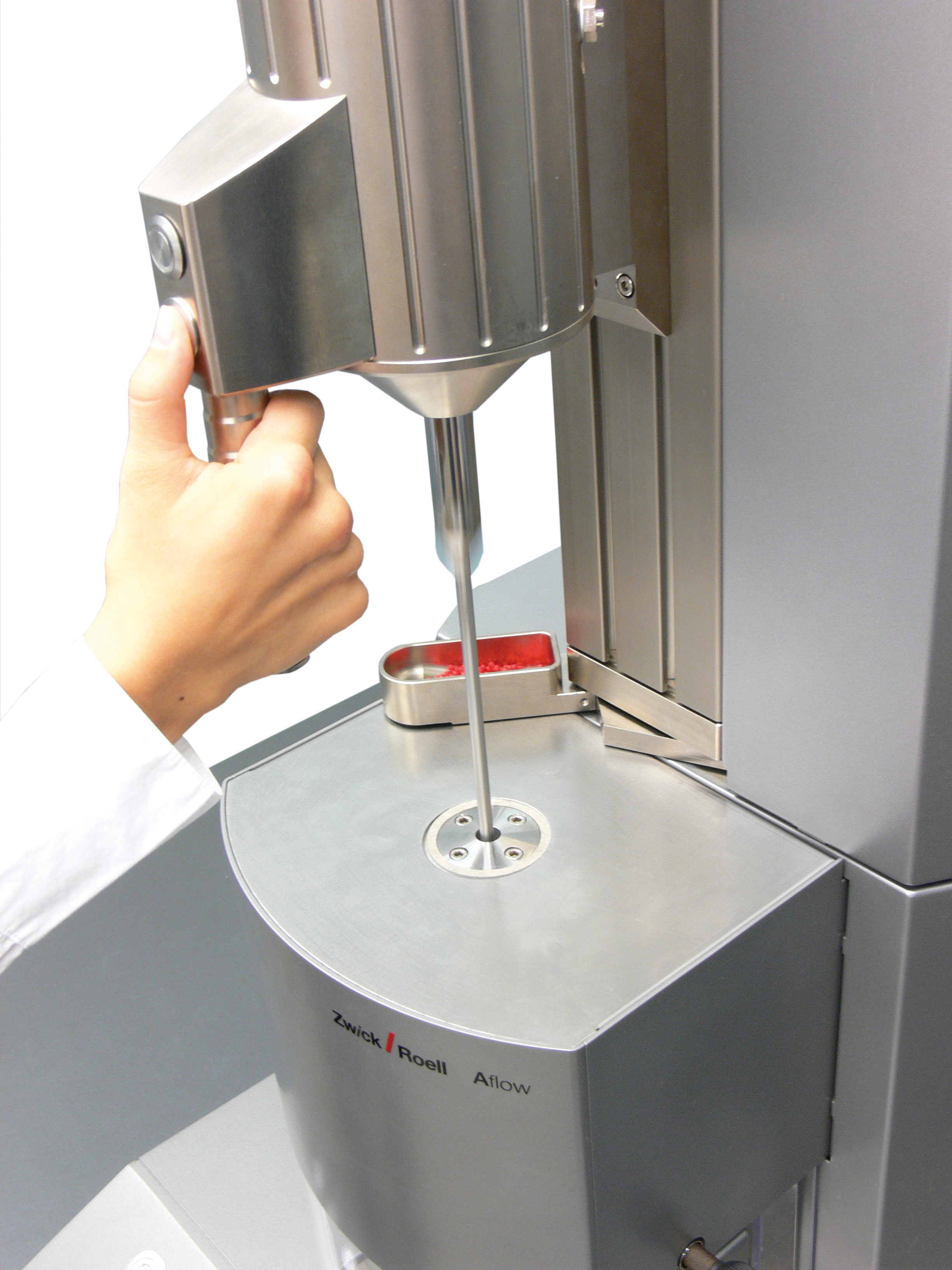

Overcoming the challenges of melt index testing with the Aflow

The Aflow is characterized by its high level of automation. Whether simple cleaning and defined pre-compaction at the press of a button, or steplessly adjustable test loads, the Aflow extrusion plastometer adapts to your testing needs:

- The Aflow was specially developed for research and development, shift work with changing operators and production control, where speed, operator-independent testing and a high level of repeatability and reproducibility of test results play an important role.

- The instrument supports worldwide common standards and methods: ISO 1133, ASTM D1238, ASTM D3364, JIS K 7210 for MFR and MVR measurement according to methods A, B, C and D.

The Aflow can be operated as a stand-alone instrument using its modern touch display, or with ZwickRoell’s testXpert testing software via PC.

Optimize ASTM D1238 Testing with ZwickRoell

Automate MFR and MVR test sequences with the force-controlled Aflow extrusion plastometer. Enhance efficiency, ensure reproducibility, and simplify compliance across different locations and users. Learn more…

| Standards | ISO 1133, ASTM D1238, ASTM D3364, JIS K 7210 | |||

| Weight levels | 0.325 ... 50 kg | |||

| Typical measurement range | Approx. 0.1 g/10 min ... approx. 900 g/10 min | |||

High level of automation

| ||||

| Test Methods | Test results | Level of automation | ||

|---|---|---|---|---|

| Method A | MFR in g/10 min |

| ||

| Method B | MVR in cm³/10 min Melt density, apparent shear rate, apparent shear stress, apparent viscosity |

| ||

| Method C half-die | ||||

| Method D multi-weight test | MFR, MVR, FRR Melt density, apparent shear rate, apparent shear stress, apparent viscosity |

| ||