- MFR

- MVR

- Average

- Incoming goods inspection

- Teaching & training

- Production control

- F&E

- Method A

- Method B

- Method C

5 quick facts about the new generation of the Mflow extrusion plastometer:

- Operation is even more intuitive

- Optimal ergonomics at any height level

- Easy to clean thanks to stainless steel surfaces

- Increased efficiency with every test run

- Higher level of safety for the user and reliability of the test results

Video: Standard-Compliant MFR Test and MVR Measurements with the Mflow

Tests according to standards ISO 1133-1,-2 (methods A and B), ASTM D1238 (methods A, B and C), ASTM D3364 and JIS K 7210

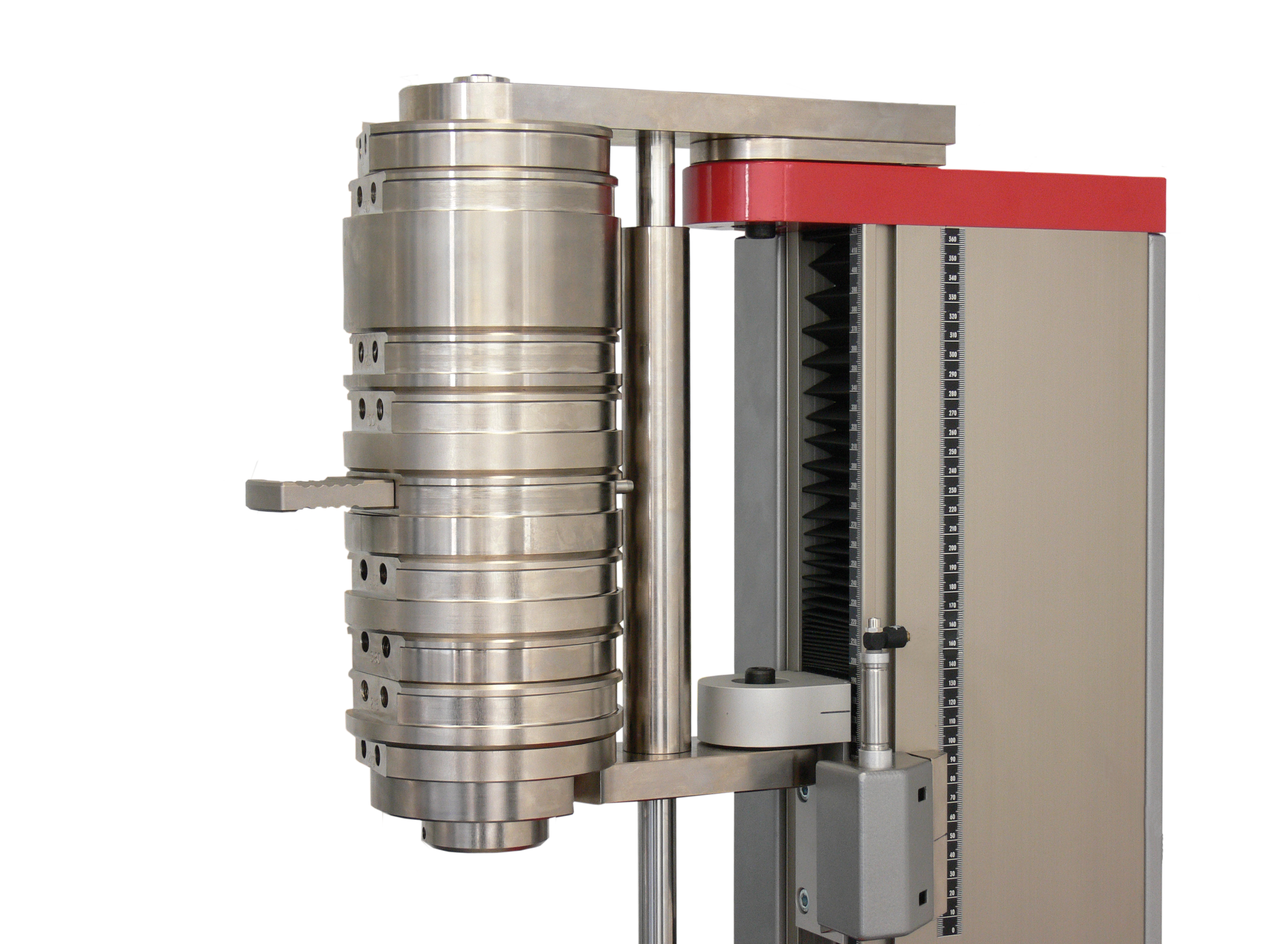

Mflow - modular, easy, reliable

High test volumes, common for many raw material manufacturers, compounders and test laboratories, imply constantly increasing demands on test equipment, test methods and automation processes. A testing instrument should therefore be perfectly adaptable to changing workflows and be flexible in terms of applications. Modular, easy and reliable - for the user, laboratory manager and decision maker.

Mflow extrusion plastometer versions

The modularity of the Mflow offers a number of advantages

The Mflow extrusion plastometer integrates all these requirements into a single instrument. Its modular design ensures:

- A high level of automation

- Simplified processes

- Reliable test results

- Flexible application options

- Intuitive operation

- Utmost safety for the user

- Fast familiarization

- Smooth processes

- Compatible workflows

Wide range of applications and all around care-free package

Flexibility, traceability and accreditation are crucial elements within the plastics industry. We know how essential it is to continuously optimize production and how important the condition of the machine is. With ZwickRoell you not only get a robust extrusion plastometer, but also qualified, worldwide service, such as our on-site calibration service in accordance with DAkkS.

The all around care-free package

Our smart testXpert testing software makes it extremely easy to adhere to precisely defined procedures and carry out every test run in accordance with industry standards. It automatically supports you in maintaining your accreditation and compliance with ISO 17025. With our testing software, all processes and results are traceable and clearly documented.

Our supplementary training courses are designed to enhance proficiency at every stage of testing, transforming your testers into experts directly at the instrument, whether they test 24/7 or just on occasion.

And should there ever be a problem with your extrusion plastometer, we guarantee worldwide availability of spare parts and fast support.

Test happy — operating the Mflow is just that easy

To meet the challenges of modern materials testing, we have made operation of the Mflow simple, safe and intuitive. The Mflow helps you achieve test results that you can rely on. Because the more complex your test requirements are, the more likely that errors can occur—and this is exactly what we set out to avoid! With our Mflow, every employee can measure safely—no cheat sheet required.

Here's what makes operating the Mflow so easy

- No cleaning effort required thanks to our cleaning option

- Lower operating height and therefore higher ergonomics for the user

- The die can be conveniently unlocked with a flick of the wrist, making it very easy to clean the extrusion barrel

- Optimally accessible extrudate cutter

- Software-controlled opening of the die plug for the measurement of very high MVR values

- Automatic weight lifting with our without weight magazine

A focus on error-free workflows

The Mflow extrusion plastometer is modularly expandable and can be adapted to your testing requirements and workflow at any time!

Advantages at a glance:

- Simple operation – also for employees who test infrequently

- Fewer manual settings reduce the likelihood of errors and ensure reliable test results

- Workflow-optimized handling

- Step-by-step software-guided instructions ensure accurate measurements without the need for cheat-sheets

Safety First! What we want you to know about safety and reliability: for users and test results

Health is our most valuable asset. Protecting it and guaranteeing the safety of your employees is a top priority. And the same holds true for us when developing new products—we make safety our top priority,

while also ensuring reliability of the test results. Only those who can rely 100% on their measurement results can relax at the end of the day and test happy!

That ensures safety and reliability

Therefore, when developing the Mflow, we paid particular attention to what really matters to you at the end of the day:

- Workflow efficiency

- Maintaining production

- Compliance with laboratory accreditation, e.g. in accordance with ISO 17025

- Maintaining product quality

- Training your test personnel

- Adhering to your business case

- Adhering to planned budgets

- Flexibility in terms of test materials

- Guaranteed spare parts availability

All of which greatly supports operators with their daily tasks

- High MVR measured value resolution enables extremely fast measured value acquisition in combination with high-resolution, digital displacement measurement for a transparent and reliable test sequence

- Live MVR display for traceable measurement

- Automatic bubble detection to avoid incorrect measurements

- Safe positioning of the test weights, which reduces the risk of work-related accidents

- Weight selector and weight lifting unit

| Test methods | Test results | Level of automation | ||

|---|---|---|---|---|

| Standards | ISO 1133, ASTM D1238 , ASTM D3364 , JIS K 7210 | |||

| Typical measurement range | Min: approx. 0.1 g/10 min ... max: approx. 2000 g/10 min | |||

| Weight levels | 0.325 ... 21.6 kg | |||

Medium level of automation

| ||||

| Method A |

|

| ||

| Method B |

|

| ||

| Method C Half-die | ||||

With the Mflow, you not only obtain reliable test results, but also benefit from the proven quality of ZwickRoell. Join a powerful network with outstanding market references.

Our audit-proof documentation, guaranteed spare parts availability, and exceptional training and further education services complete our partnership with customers.

Need more information or have more questions? We’re excited to hear from you!

Mflow FAQs

Yes, all options such as the weight lifting unit, the cleaning function or a nozzle closure can be retrofitted as required and combined with the existing options.

Yes, not only granulate or flakes, but also powdery materials can be filled in through the supplied funnel. However, you need to make sure that the powder is filled in quickly to prevent the material from melting and sticking to the upper area of the extrusion barrel. We also recommend the use of a die plug to prevent the powder from trickling out.

Yes, the Mflow is ideally suited for measuring materials with very high MVR values thanks to the use of dead weights and the high data acquisition rate. However, a die plug is required for such tests, as this low-viscosity material must be prevented from flowing out during the preheating time.

Yes, fluorine-containing materials such as PTFE or PFAs can also be tested with the Mflow. But please note: with these polymers, it is important to use extrusion barrels and pistons made of a special steel alloy to ensure greater resistance and durability. This is because the melting of these polymers can produce an acid that attacks the material of conventional extrusion barrels and pistons.

The test weights always interlock securely and are designed in such a way that it is impossible for the weights to tip over. This ensures safety for both the operator and the instrument. If you frequently change to different test loads or regularly use high loads, we recommend the use of a pneumatic weight lifting device with weight selector. This means that the weights no longer have to be moved manually. And the risk of dropping weights is completely eliminated.

Yes, the Mflow can also be used without a PC and testing software, in which case it is operated exclusively via the device's touchscreen. More than 100 test results can be saved in standalone mode and exported via USB stick. However, some functions, such as report generation or connection to a LIMS system, are not possible or only available to a limited extent when compared to using the testXpert testing software.

Yes, up to six extrusion plastometers can be connected to a PC via an Ethernet switch.

The test parameters are set out in the specification standards for the individual polymers. You can find an overview here.