Test methods

- Rockwell

- Super Rockwell

- Ball indentation hardness

- Carbon testing

- Vickers (HVT)

- Brinell (HBT)

Test load

- 1 ... 250 kg

Standards

- ISO 6508

- ISO 2039-1

- ASTM E18

- DIN 51917

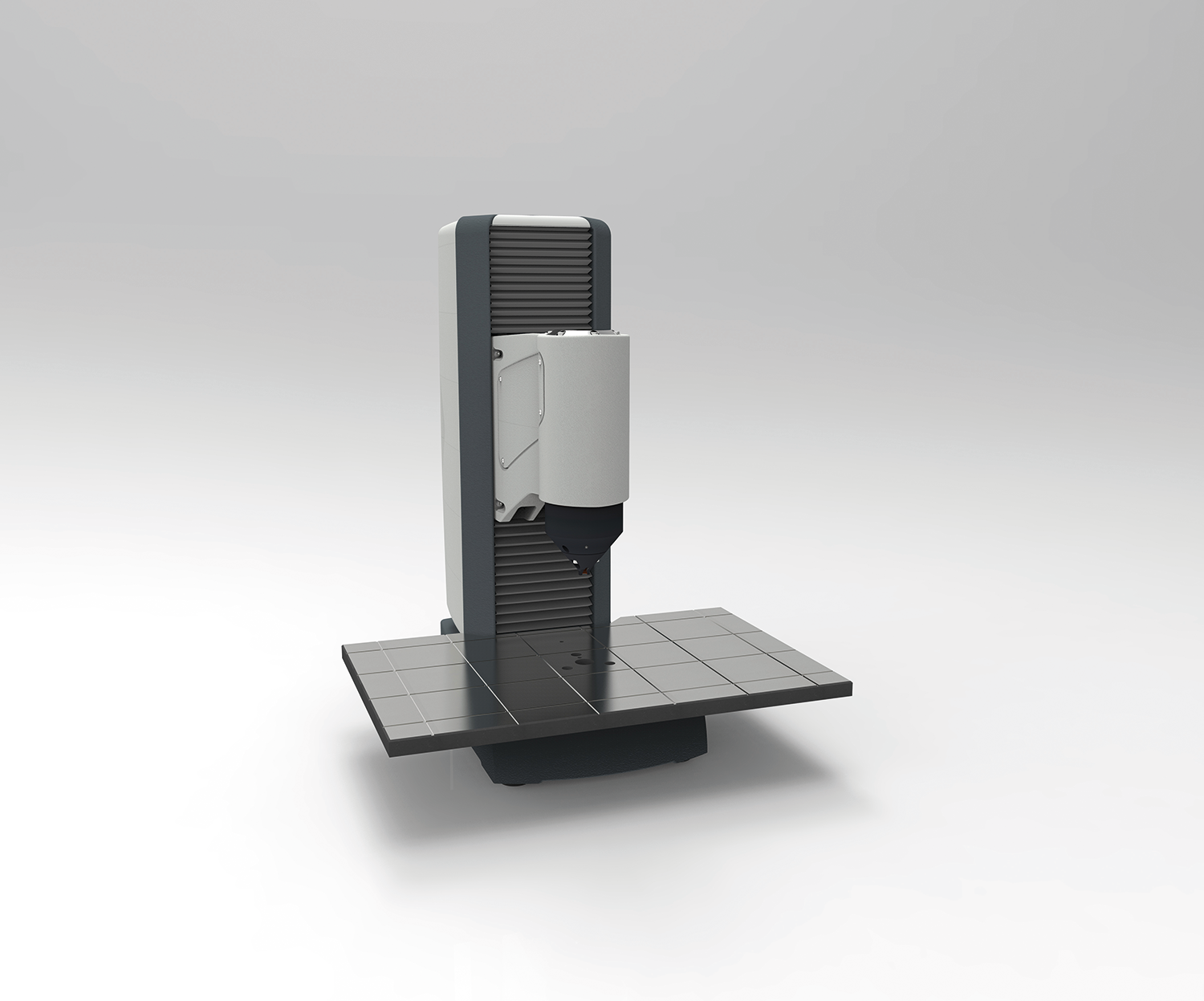

DuraJet - the hardness testing multi-talent

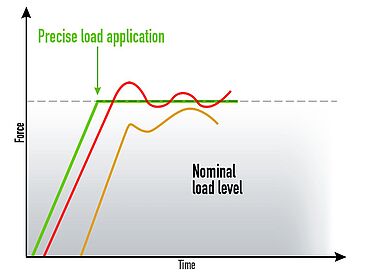

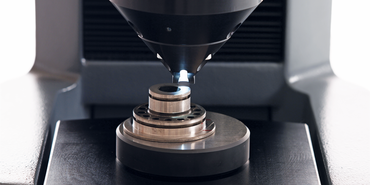

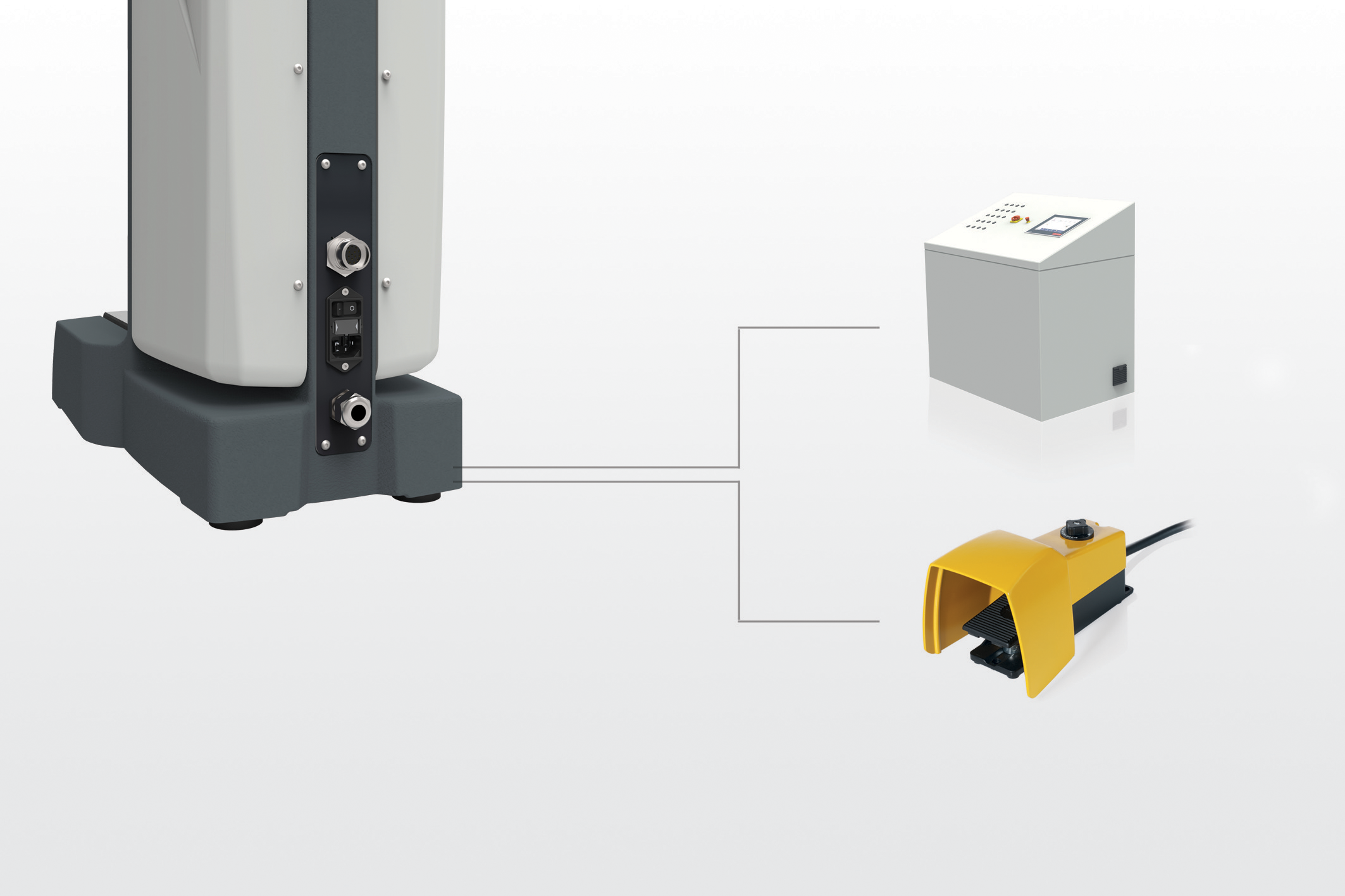

Robust and versatile – the key characteristics of the DuraJet. Through electronic load application and a load range of 9.8 N to 2,450 N (1 kg to 250 kg), this hardness testing machine covers the complete Rockwell hardness range. But that's not all, this hardness tester can do even more: Plastics and carbon testing as well as Vickers hardness tests and Brinell hardness tests can be performed in depth.

Flexibility combined with ease of operation allow the DuraJet testing instrument to be implemented in situations where up to now several devices had to be used with different configurations.

A look at the different hardness testing methods

- In addition to the entire Rockwell range, the DuraJet also covers the Brinell and Vickers methods in depth in a load range of 1-250 kg.

- It can also be used for plastics and carbon testing.

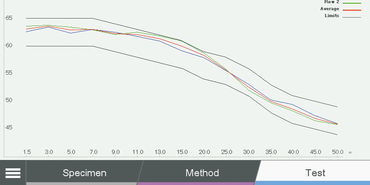

- In the ecos Workflow DuraJet edition testing software, your results can also be converted to other test methods according to standard.

DuraJet technical data

| Load range | 9.8 ... 2,450 N (1 kg ... 250 kg) |

| Clamping insert outer diameter (standard) | Ø 15 mm |

| Clamping insert inner diameter (standard) | Ø 8 mm |

| Motorized height adjustment of test unit | 6 mm/sec |

| Dimensions (W x H x D) | 300 x 740 x 565 (mm) |

| Weight | 110 kg |

| Max. test height | 260 mm |

| Test anvil mounting | Ø 25 mm |

| Load measurement resolution | 24 bit |

| Depth measurement resolution | 0.02 µm |

| Interfaces | 2x USB, RJ45 |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 120 W |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 90% (non condensing) |

| Max. work piece weight | 100 kg |

| Protection class to EN 60529 | IP20 |