Tensile Testing Machines and Testers

A tensile tester or tensile testing machine is used to determine the strength and deformation behavior of a material up to the point of fracture. Choosing the right tensile testing machine depends on the material to be tested and the standard(s) that must be followed.

What is a tensile tester? Types of tensile testers Video: zwickiLine Typical machine components Automated tensile testing What is a tensile test? Application examples Standards Choosing the right machine

Detailed information on tensile tests:

General information ISO 527 ASTM D638 ISO 6892 ISO 6892-2 ASTM E8 ASTM E21

What is a tensile tester?

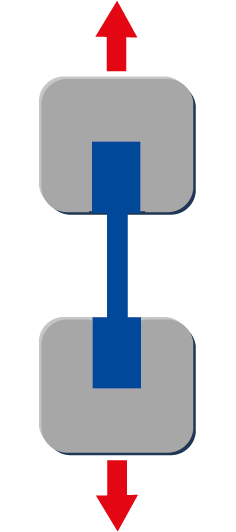

A tensile tester, also known as a pull tester or univeral testing machine (UTM), is an electromechanical test system that applies a tensile (pull) force to a material to determine the tensile strength and deformation behavior until break.

A typical tensile testing machine consists of a load cell, crosshead, extensometer, specimen grips, electronics and a drive system. It is controlled by testing software used to define machine and safety settings and store test parameters specified by testing standards such as ASTM and ISO. The amount of force applied to the machine and the elongation of the specimen are recorded throughout the test. Measuring the force required to stretch or elongate a material to the point of permanent deformation or break helps designers and manufacturers predict how materials will perform when implemented for their intended purpose.

ZwickRoell tensile test machines, including the zwickiLine, ProLine, AllroundLine and E-series machine (tensile testing machine for large test forces starting at 330 kN), are specifically designed to meet customer requirements based on testing capacity, types of material, applications, and industry standards such as ASTM E8 for metals, ASTM D638 for plastics, ASTM D412 for elastomers, and many more. In addition to overall system safety and reliability, ZwickRoell designs and builds every universal testing machine with a focus on providing:

- A high level of flexibility through ease of operation

- Simple adaptations to customer- and standard-specific requirements

- Future-proof expansion capabilities to grow with your needs

What are the typical components of a tensile testing machine?

- LOAD CELLS (1)

The load cell converts the tensile force into an electrical signal that can be measured. ZwickRoell load cells not only guarantee high product quality, but also seamless compatibility with all our machine components. - EXTENSOMETERS (2)

An extensometer is a strain measuring device that measures the strain of a specimen, also referred to as strain measurement. Strain measurement for tensile tests is required by almost every standard, such as ASTM and ISO. - SPECIMEN GRIPS (3)

Specimen grips provide the mechanical connection between the specimen and the tensile testing machine. Their function is to transfer the movement of the crosshead to the specimen and transfer the test force generated in the specimen to the load cell. - MOVING CROSSHEAD (4)

The moving crosshead is essentially a crosshead that is controlled to move up or down. In a tensile test, the crosshead speed of the testing machine is directly related to the strain rate in a specimen. - ELECTRONICS (5)

The electronics control the moving parts of the tensile testing machine. The speed of crosshead and thus the load rate can be controlled by a microprocessor in the servo controller (motor, feedback device and controller). - SOFTWARE (7)

Our testing software is an extremely user-friendly, wizard guided, Windows-based solution that allows the user to set up the testing system, configure and run tests and display the results. - DRIVE SYSTEM (6)

The drive system supplies the motor of the tensile testing machine with different levels of power and frequencies, indirectly controlling the motor speed and torque.

All components of a ZwickRoell tensile testing machine are designed to work together seamlessly.

Automated tensile testing

For automated tensile tests, the testing machine is supplemented with a robotic testing system, which removes specimens from a magazine and inserts them in the specimen grips of the machine. A 2D code reader, cross-section measuring device or, depending on the test, a hardness tester or roughness measuring system can also be connected. Disposal of specimen remains is also handled by the automated tensile testing system.

The benefits provided by robotic systems apply to both large and small test series:

- Up until now, automated tensile testing has mainly been used by laboratories with high specimen volumes. Without the need for operator attendance, the fully automatic tensile testing system can be used for night shifts and over the weekend, with a consistent high level of efficiency, 24/7.

- Even for small test series starting with approximately 10 specimens, an automated tensile testing system proves worthwhile. With the use of a simple robotic testing system for tensile tests, qualified laboratory personnel are relieved of routine responsibilities and therefore available for more complex tasks.

The fully automatic tensile test eliminates subjective operator influences, such as hand temperature or skewed specimen gripping on the specimen and test assembly. This results in a high level of accuracy and reproducibility, and the quality of test results is significantly improved.

ZwickRoell is a global leader in materials testing and offers a deep level of expertise in automated tensile testing. We have delivered over 600 automated testing systems worldwide and continue to install approximately 40 systems every year. We take pride in our ability to match the right testing solution to each client’s unique business requirements, providing tailored solutions backed by long-term service and support partnerships.

If you are interested in learning more about the right robotic tensile testing solution for your test challenges, we encourage you to reach out to our team.

What is a tensile test?

A tensile test is a test method used to determine how a material reacts to an applied (pulling) force. Properties that are measured directly in a tensile test include tensile strength, maximum extension and reduction of area. These measurements can also be used to determine the following characteristics: Young's modulus, deformation (Poisson’s ratio), yield point and hardening properties.

- Tensile strength - the maximum mechanical tensile stress a material can sustain before fracture

- Maximum extension - the maximum elongation that a material can undergo before it fails

- Reduction of area - comparison of the initial cross-sectional area of a specimen and the smallest cross-sectional area of the same specimen after complete fracture. This serves as an indicator of how much a material deforms under tensile load.

- Young’s modulus - essentially the stiffness of a material. That is, it indicates how easy it is to bend or stretch a material:

- Young's modulus = stress/elongation

- Stress = force/cross-sectional area

- Extension = change in length/original length

- Poisson’s ratio – the ratio between the change in width and the change in length in the direction of the stretching force.

- Yield point – the maximum tensile stress that an elastic material can sustain before it permanently deforms.

- Properties of stain hardening - strain hardening occurs when a material is stretched beyond the yield point. Strain hardening increases the mechanical strength and hardness, but reduces the ductility. Manufacturers can use this information to determine the material that meets the ductility requirements while simultaneously displaying the highest possible strength.

The data obtained during a tensile test can be plotted on a graph to produce a stress/strain curve.

This stress/strain curve shows a curve with a high level of strain hardening (1) and with a low level of strain hardening (2) after the yield point.

Manufactures in every industry from plastics and composites, to automotive, food and beverage and the highly regulated medical and pharmaceutical industry use tensile testing equipment to perform industry-standard tests to precisely measure the defining properties of their material, ensure standard-compliance, and ultimately be able to guarantee the quality and safety of their products.

Tensile testing application examples include:

- Plastic packaging − tensile force is applied to a plastic material specimen to help manufacturers determine the protective characteristics of the plastic when it is subjected to pulling forces like those that occur during shipping processes, for example.

- Concrete-reinforcing steel bars − tensile tests on metal specimens are used to determine various mechanical properties such as yield strength, ultimate tensile strength, elongation, and reduction of area to help manufacturers not only meet advertised quality and high-performance specifications but to comply with industry standards to ensure that products are safe for market release.

- Rubber compounds for use in tires – the elongation and tensile strength of tire rubber is tested for quality control purposes to avoid tire failures such as tread separation and blowouts.

Common standards for tensile testing

ASTM and ISO are two common standards for materials testing. These are some of most frequently used standards for tensile testing:

- Metals - ASTM E8 / ASTM E21 / ISO 6892-1 / ISO 6892-2

- Plastics - ASTM D638 / ISO 527-2

- Rubber and elastomers - ASTM D412 / ISO 37

- Composites - ASTM D3039 / ISO 527-4/-5

What do I look for when choosing a tensile testing machine?

After quality, reliability of test results, cost, and application, many other factors should be taken into consideration when choosing your machine:

- Flexibility – the ability to test a wide range of materials in a wide load range, the integration and easy change between accessories specifically designed for individual industry standards, types of material and applications, the option to operate the machine with or without a PC, and the mechanical modularity that allows for expansion and adaptation of your machine using many available test fixtures and specimen grips, all contribute to the overall flexibility of your testing machine.

- Safety – the safety of your tensile tester is imperative and extends from the implementation of physical safety features such as external safety doors, safety enclosures, safety interlocks and limit switches to software system monitoring and user management. ZwickRoell is dedicated to designing our testing systems with operator and machine safety at the forefront.

- Ease of use – the key is to choose a testing system that is both sophisticated by design and operability, while at the same time allowing operators to easily install test fixtures, set up test configurations, implement test programs, run tests, and interpret results.

- Adaptability – market developments and standard requirements are always evolving. When deciding on a tensile tester, you should make sure that your machine is able to adapt to these changes - from accessories and fixtures to the electronics and software programs.

- Software – testing software is intended to make the testing process easier for the operator and ensure uniform and standard-compliant test configurations. Our testing software is designed with the user and laboratory workflow in mind.

- Standards library – our testing software includes over 600 standard test programs, which allows you to select the right standard-compliant program for your application, simplifying test setup and configuration, and ultimately saving you time and effort and reducing the possibility of errors. For tests that go beyond the standard or for the ability to freely configure the test sequence of your machine, our software offers pre-prepared master test programs.

- Intelligent wizard – an intelligent wizard guides the user through the test configuration. Data is automatically checked for plausibility.

- Reports – whether they are simple or customized, our software allows you to define reports with virtually unlimited possibilities along with the option to save, export, and print.

- Automation - there is an increasing rate in the use of automation in materials testing, especially since even the smallest disruptions can alter measured values. ZwickRoell offers a wide range of possibilities for automation in materials testing. Testing systems range from efficient automation of small series tests using collaborating robots in the lab to fully automated testing laboratories that work around the clock.

- Aftermarket support – ZwickRoell provides individually tailored services and support throughout the entire lifecycle of our testing machine. We provide expert calibration services, preventive maintenance and inspection, training courses, machine relocation services, qualification services, a hotline and customer support and guaranteed spare parts availability for at least 10 years after a product has been discontinued.

- Company stability – ZwickRoell history dates back more than 160 years. We proudly stand on a solid foundation of 187 product and industry experts, 347 service employees, 80,000,000 tests performed by our machines annually.

Frequently asked questions

A tensile tester, also known as a pull tester or universal testing machine (UTM), is an electromechanical test system that applies a tensile (pull) force to a material to determine the tensile strength and deformation behavior until break.

To test tensile strength, a tensile testing machine (tensile tester), or universal testing machine, that is a materials testing machine is used. This electromechanical testing system applies a controlled force and strain to a material and measures the force required to stretch or elongate the material to the point of permanent deformation or fracture.

First, the specimen is gripped in the jaws of the universal testing machine. The specimen is then uniformly stretched until it breaks. During the full duration of the test, the strain and the tensile force are measured, recorded and evaluated.