ZHN Nanoindenter

Download- Hardness testing to ISO 14577

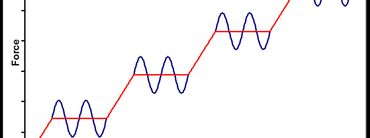

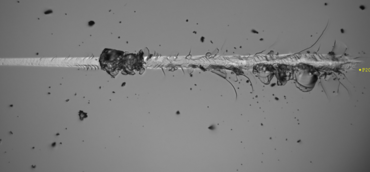

- Scratch tests

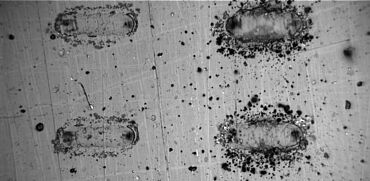

- Wear tests

- Dynamic tests

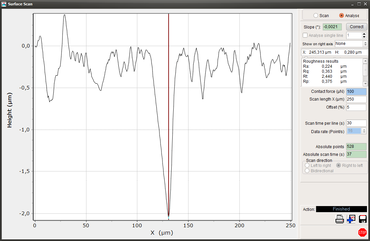

- Profilometer

- 0 - 20 N

- ZHN for research & development

- ZHN-S for quality control and standard test tasks

A new dimension

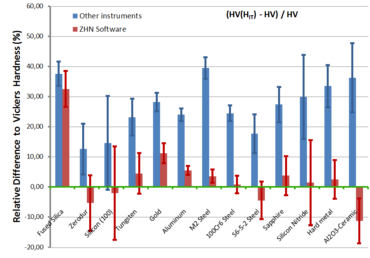

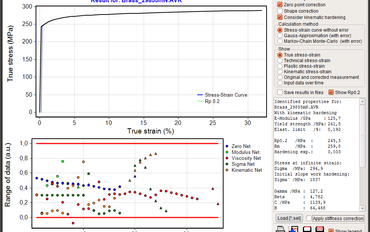

The ZHN nanoindenter is used for comprehensive, mechanical characterization of thin layers or small surface areas with the necessary force and travel resolution. This includes measuring indentation hardness, indentation modulus, and Martens hardness to ISO 14577 (instrumented indentation testing).

Technical overview

The modular design of the universal ZHN nanoindenter consists of:

- Two-column load frame with central lead screw drive, precision guidance and granite base

- Motorized central lead screw drive and programmable motorized X-Y table

- Three-axis step motor controller as PCl-E plug-in board

- Tandem microscope with two cameras and LED incident light, green LED

- Control electronics for machine and measuring head

- Interchangeable measuring heads up to 20 N

- InspectorX control and evaluation software

- Software modules for Autofocus

- Software module for overview image from combined individual images with large depth of field

ZwickRoell has implemented the radial displacement correction option in InspectorX in compliance with ISO 14577:2015

ZHN-S version for standard test tasks

The ZHN-S version was configured for quality control and standard test task purposes. Because this robust nanonindenter is easy to operate, it does not require a specialist. Animations and predefined applications in InspectorX support the operator during test preparation and test performance. Operating errors are reduced and a short training period is ensured.

The ZHN-S nanonindenter is permanently equipped with a NFU measuring head. The evaluation process is also simple: and automatic fit function and range selection for measurement data analysis simplify the evaluation of measurements on coatings.

Downloads

- Product brochure: Hardness Testing with ZwickRoell PDF 25 MB

- Product information: ZHN – universal nanomechanical testing system PDF 2 MB

- Product information: Specimen grips for the ZHN nanoindenter PDF 361 KB

- Product Information: ZHN-S – Nanoindenter for Standard Test Tasks PDF 3 MB

- Product information: ZHN/SEM – nanoindenter for scanning electron microscope PDF 1 MB

- Product information: Specimen heater up to 400 °C for high-temperature nanoindentation PDF 418 KB