Applications

- Nanoindentation

Special feature

- Testing software for nanoindentation

Windows compatible

- Windows 10 optimized

Thin layers perfectly analyzed

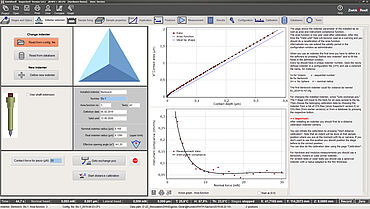

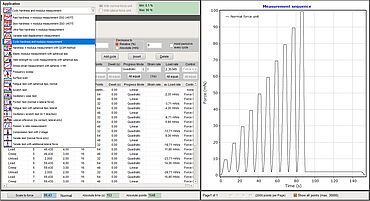

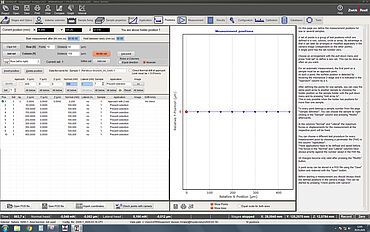

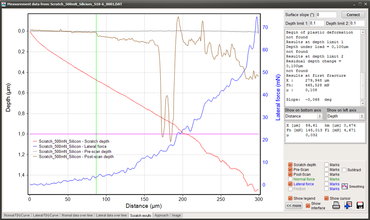

InspectorX is the intuitive control and evaluation software for force-indentation curves used to determine mechanical parameters with the universal ZHN nanoindenter. For small depths of indentation it is very important to gain a high accuracy of the correction functions for the tip shape as well as for the zero point (position of the surface) and thermal drift.

With the testing software InspectorX you can use and analyze the following hardness testers:

- ZHN Nanoindenter

- ZHN/SEM

- ZHU/zwickiLine+

Advantages and features

InspectorX offers particularly sophisticated correction routines and algorithms, whose quality was proven, for instance, by comparative measurements of the Federal Institute for Materials Research and Testing (BAM) :

- Determination, description and correction of instrument compliance or stiffness

- Determination and description of indenter area function (27 different fi t functions available)

- Zero point correction (automatic or manual)

- Thermal drift correction (automatic or manual)

- Creep analysis (fi t of the creep curve, calculation of creep rate)

- Analysis of dynamic data (continuous or quasi continuous stiffness measurement)

- Special analysis of wholly elastic measurements using a Hertzian contact model for coated materials with up to three layers

- Determination of stress-strain curves of metals from indentations with spherical indenters