Autoinjector testing systems

Download

Versions

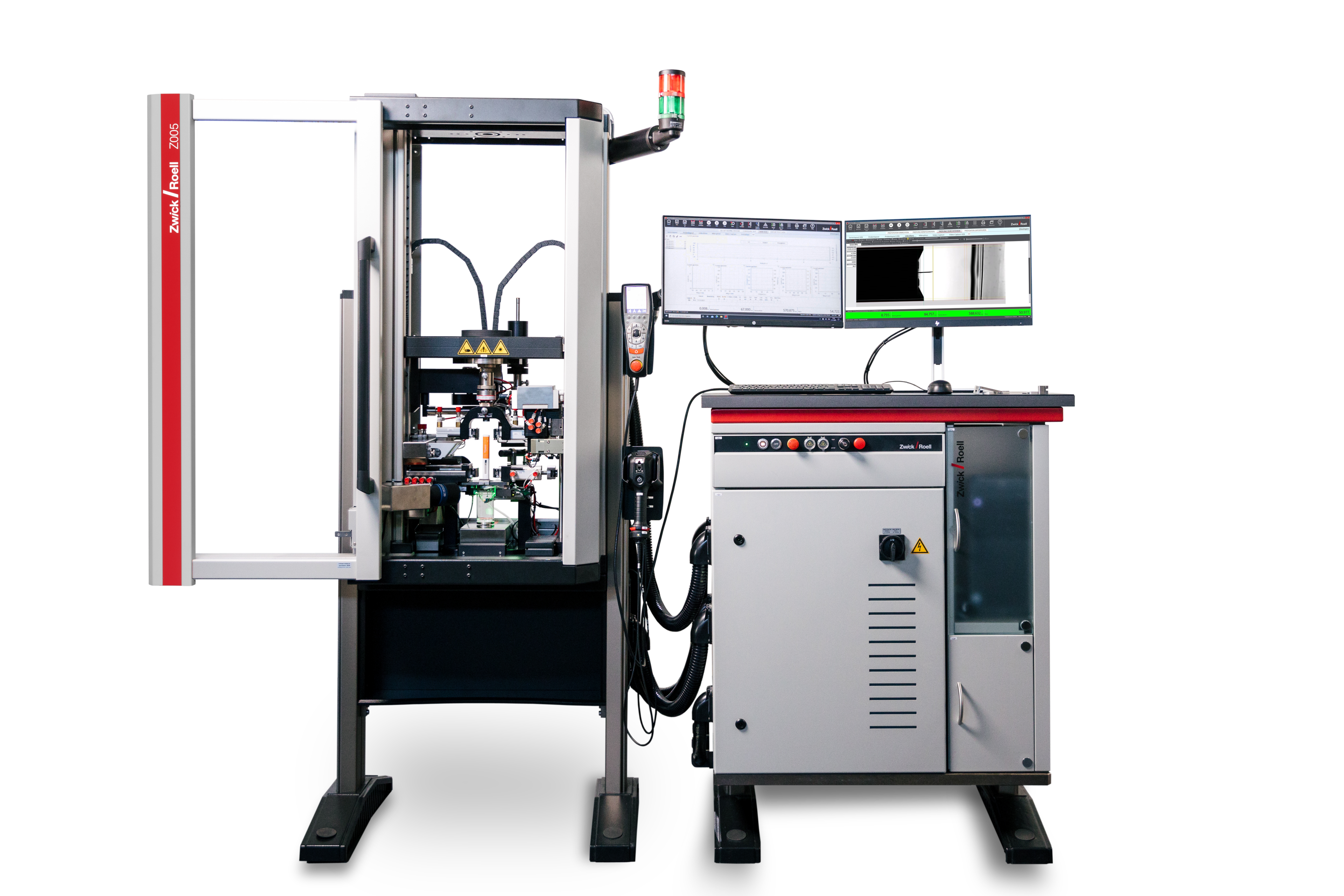

- AllroundLine 5 kN

- zwickiLine 2.5kN

Special feature

- Multifunctional platform

- Daily Checks for all sensors

- PokaYoke error prevention

- For different types of autoinjectors

- Comprehensive range of services

- 21 CFR Part 11 requirements

Standards

- ISO 11608-5

- EN 13849-1

Autoinjector testing systems from ZwickRoell: reliable test results guaranteed

Autoinjectors and pens used for the subcutaneous administration of medications, represent a fast-growing market segment of medical products.

To ensure that these devices function reliably and safely, they must be thoroughly tested by both autoinjector manufacturers and pharmaceutical companies, who fill them. For this purpose, reproducibility and traceability of test results, as well as reduced operator influences are of critical importance.

Videos on autoinjector testing systems

Impressions about the AllroundLine autoinjector testing system

Technical data

- High operating comfort

- High test speed consistent through to the nominal force

- Ergonomically adjustable working height through support legs

- Low noise generation

- Powerful, maintenance-free drive

The testing system can be used in a temperature range of +10 ... +35 °C.

| Type | Z005 TN | |

| Test load Fmax | 5 | kN |

| Test area | ||

| Height | ||

| Lower test area | 1030 | mm |

| Upper test area (additional crosshead required) | 1015 | mm |

| Width | 440 | mm |

| Load frame | ||

| Dimensions | ||

| Height | 1314 | mm |

| Width | 680 | mm |

| Relative humidity (non-condensing) | 20 ... 90 | % |

| Weight | ||

| Average noise level at vmax measured at 1 m distance from the front of the machine | 67 | dB(A) |

| Drive system | ||

| Motor | AC servo motor with concentrated windings, Hiperface® motor feedback system | |

| Crosshead speed vmin ... vmax | 0.0005 ... 30001 | mm/min |

| Crosshead return speed, max. | 30001 | mm/min |

| Drive travel resolution | 0.959431 | nm |

| Positioning repeatability (without reversal of direction) | ±2.0 | µm |

| Controller | Adaptive | |

| Cycle time | 1000 | Hz |

- Values apply to machines with the safety doors closed in automatic mode and to machines without safety devices. For machines with the safety door open, the speed is reduced to 600 mm/min.

Autoinjector testing machine

| Test load Fmax | 2.5 | kN |

| Load frame | ||

| Ambient temperature | +10 ... +35 | °C |

| Pneumatic control unit | ||

| Ambient temperature | +10 ... +35 | °C |

| Drive | ||

| Motor | DC servo motor | |

| Control, set value preselection | Digital | |

| Crosshead speed vmin ... vmax | 0.0005 ... 10001 | mm/min |

| Drive travel resolution | 0.0277 | μm |

| Positioning repeatability (without reversing directions) | ±2 | μm |

- Values apply to machines with closed safety door and closed safety guard in automatic mode and to machines without safety device and/or without safety guard. For machines with the safety door and/or safety guard open, the speed is reduced to 600 mm/min.