- 50 - 100 kN

- -80 to +2,000°C

- CF, LCF

- CCG, CFCG

- FCGR,TMF

- SSRT, HE

- Creep

- Stress Relax

- Tensile

- Compression

- Flexure

- ISO 204

- ASTM E139

- EN 2002-005

- ASTM E2714

- ASTM E2760

- European CoP for TMF

The optimal testing machine for demanding tests, also under alternating load

This patented electromechanical fatigue testing machine with backlash-free zero crossing features a central lead screw and is ideal for force and strain controlled creep fatigue tests. The Kappa SS-CF provides extremely high flexibility, covers the complete range of creep testing applications and is ideal for a wide range of creep tests with alternating load at both ambient and high-temperature conditions.

- Force and strain controlled creep fatigue tests with alternating load (through zero)

e.g. CF, LCF, CFCG and TMF tests - Advanced creep tests

- Fatigue tests with threshold and alternating load

- Strain modeling (e.g. determination of creep curve at different loads)

- Creep test with slow strain rates (SSRT)

- Creep data from components tests - Static and cyclic crack growth/widening test

- Determination of hydrogen embrittlement

- Tests with stepless force and temperature adjustment

- Relaxation tests

- Creep test up to break

- Creep rupture

- Stress rupture - Classic creep tests

- Short-term tensile, compression and flexure tests can also be performed with this testing machine

The Kappa SS-CF in use

Technical overview

| Type | Kappa 50 SS-CF |

| Test load, max. Fmax | 50 kN |

| Test frame dimensions | |

| Width | 860 mm |

| Depth | 655 mm |

| Height | 2212 mm |

| Test area depth | Unlimited |

| Test area width between the lead screws | 720 mm |

| Test area height, max. | 1090 mm |

| Crosshead travel | 200 mm |

| Lateral guidance of the moving crosshead via precision bearings on four hard-chromed guide columns | Diameter 40 mm |

| Test speed range | 0,001 mm/h to 250 mm/min |

| Test speed accuracy (measured over an interval of min. 5 s or 10 mm travel) | < ± 0,1 % |

| Position transducer travel resolution | 0.14 nm |

| Weight | 700 kg |

| Type | Kappa 100 SS-CF |

| Test load, max. Fmax | 100 kN |

| Test frame dimensions | |

| Width | 860 mm |

| Depth | 655 mm |

| Height | 2212 mm |

| Test area depth | Unlimited |

| Test area width between the lead screws | 720 mm |

| Test area height, max. | 1090 mm |

| Crosshead travel | 200 mm |

| Lateral guidance of the moving crosshead via precision bearings on four hard-chromed guide columns | Diameter 40 mm |

| Test speed range | 0,001 mm/h to 250 mm/min |

| Test speed accuracy (measured over an interval of min. 5 s or 10 mm travel) | < ± 0,1 % |

| Position transducer travel resolution | 0.14 nm |

| Weight | 700 kg |

| Temperature | Environment | Range of application | Applications | Advantages | |

|---|---|---|---|---|---|

High-temperature furnace |

|

|

|

|

|

| Induction heating system |

|

|

|

|

|

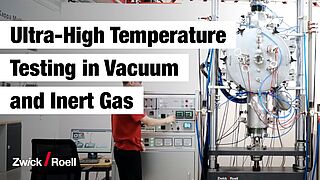

| Vacuum chamber |

|

|

|

|

|