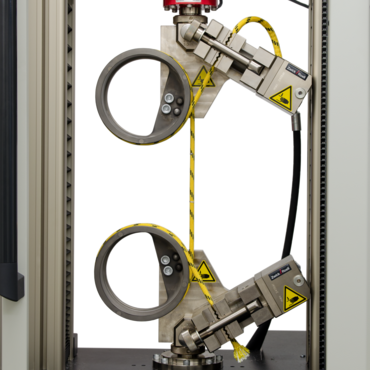

Halatlar İçin Sarmal Çeneler

İndir

Malzeme

- Plastik

- Tekstil

- Metal

Test kuvveti

- 2,5 kN - 100 kN

Numune formu

- Halat

- yüksek mukavemetli iplik

- Kablo

- Tel

Test tipi

- Çekme

Halatlar İçin Çeneler

Sarmal çene boyutsal olarak stabil olmayan çekme numunelerin testi için kullanılabilir.

Numunenin çekme kuvveti, kuvvet düşürücü makaralara sürtünmesi yoluyla azaltılmaktadır. Çekme kuvveti bir vida (genellikle kuvvet artışı ile), kama ya da hidrolik bir sıkma aparatı üzerinden mekanik sağlanmaktadır.

Toplamda beş farklı halat çenesi bulunmaktadır:

- Fmax 2,5 kN sert olmayan plastikler ve tekstiller için

- Fmax 2,5 kN metalik malzemeler, plastikler ve doğal lifler için

- Fmax 10 kN - 50 kN yüksek mukavemetli ipler ve iplikler için

- Fmax 100 kN çelik ve plastikler için

- Fmax 100 kN yüksek mukavemetli halatlar ve iplikler için

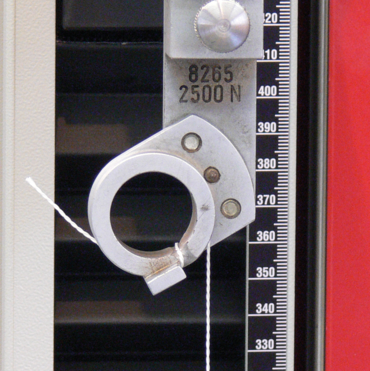

| Ürün No. | 313440 | |

| Tip | 8265 | |

| Fonksiyon prensibi/işaretleme | Düğüm ve döngü | |

| Test kuvveti Fmaks | 2,5 | kN |

| Boyut | ||

| Yükseklik | 79,7 | mm |

| Genişlik | 44 | mm |

| Derinlik | 32 | mm |

| Oluk yarıçapı | 2,5 | mm |

| Numune kalınlığı, maks. | 5 | mm |

| Bağlantı, Kilit pim | Ø 20 | mm |

| Ortam sıcaklığı | -70 ... +250 | °C |

| Çene başına ağırlık, yaklaşık | 0,18 | kg |

| Teslimat kapsamı | 2 | Adet |

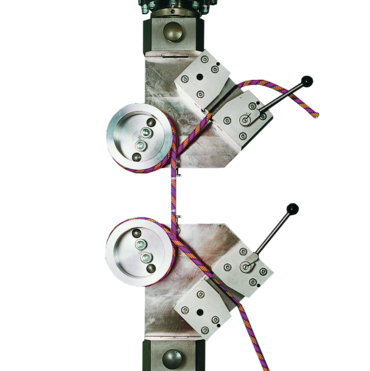

| Ürün No. | 318688 | |

| Tip | 8270 | |

| Fonksiyon prensibi/işaretleme | Sarma ve ek vidalı sıkıştırma | |

| Test kuvveti Fmaks | 2,5 | kN |

| Boyut | ||

| Yükseklik | 51 | mm |

| isteğe bağlı kuvvet kaldırma silindiri Ø30 mm ile | 118 | mm |

| isteğe bağlı kuvvet kaldırma silindiri Ø60 mm ile | 122 | mm |

| isteğe bağlı kuvvet kaldırma silindiri Ø100 mm ile | 136 | mm |

| Genişlik | 32 | mm |

| isteğe bağlı kuvvet kaldırma silindiri Ø30 ile | 174 | mm |

| isteğe bağlı kuvvet kaldırma silindiri Ø60 ile | 204 | mm |

| isteğe bağlı kuvvet kaldırma silindiri Ø100 ile | 244 | mm |

| Derinlik | 78 | mm |

| Numune boyutu | ||

| Yuvarlak numune, Ø | 8 | mm |

| Açma acısı, maks. (çene ağzı dahil) | 8 | mm |

| Bağlantı, Kilit pim | Ø 20 | mm |

| Çene başına ağırlık, yakl. | 1,5 | kg |

| Ortam sıcaklığı | -40 ... +2501 | °C |

| Teslimat kapsamı | 2 | Adet |

- Olası ısı alanı, çene ağızlarının daha küçük bir sıcaklık aralığı ile sınırlıdır.

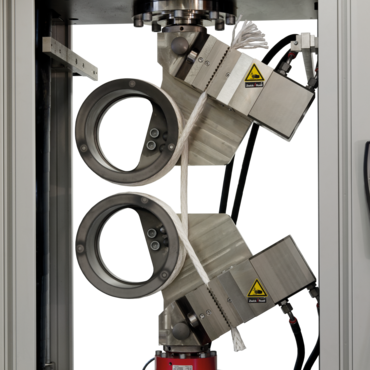

| Ürün No. | 3245661 | 3245681 | |

| Tip | 8370 | 8470 | |

| Test kuvveti Fmaks | 10 | 50 | kN |

| Bağlantı, Kilit pim | Ø 20 | Ø 36 | mm |

| Taşıma levhası başına ağırlık, yakl. | 3,6 | 3,6 | kg |

| Ortam sıcaklığı | -70 ... +250 | -70 ... +250 | °C |

| Teslimat kapsamı | 2 | 2 | Adet |

- Sadece Xforce K yük hücresi ile birlikte

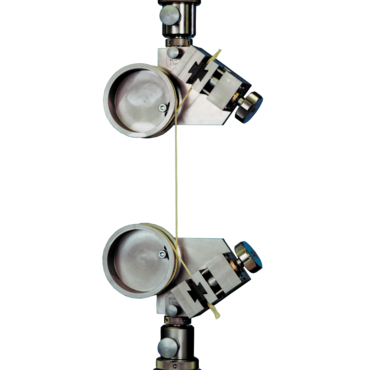

| Ürün No. | 3195791 | |

| Tip | 8570 | |

| Test kuvveti Fmaks | 100 | kN |

| Boyut | ||

| Yükseklik | 312 | mm |

| isteğe bağlı kuvvet kaldırma silindiri Ø90 mm ile | 315 | mm |

| isteğe bağlı kuvvet kaldırma silindiri Ø200 mm ile | 421 | mm |

| isteğe bağlı kuvvet kaldırma silindiri Ø280mm ile | 501 | mm |

| Genişlik | 315 | mm |

| isteğe bağlı kuvvet kaldırma silindiri Ø90 mm ile | 316 | mm |

| isteğe bağlı kuvvet kaldırma silindiri Ø200 mm ile | 347 | mm |

| isteğe bağlı kuvvet kaldırma silindiri Ø280mm ile | 370 | mm |

| Derinlik | 168 | mm |

| Bağlantı, Kilit pim | Ø 60 | mm |

| Çene başına ağırlık, yakl. | 35 | kg |

| Ortam sıcaklığı | -40 ... +2502 | °C |

| Teslimat kapsamı | 2 | Adet |

- Sadece Xforce K yük hücresi ile birlikte

- Olası ortam sıcaklığı, çene uçlarının daha küçük bir ortam sıcaklığı ile sınırlıdır.

| Ürün No. | 07296512 | |

| Tip | 8570 | |

| Test kuvveti Fmaks | 100 | kN |

| Numune boyutu | ||

| Yuvarlak numune, Ø | 30 | mm |

| Bağlantı, Kilit pim | Ø 60 | mm |

| Kilit kuvveti (basınçta, maks. 300 bar) | 170 | kN |

| Ortam sıcaklığı | +10 ... +35 | °C |

| Çene başına ağırlık, yakl. | 52 | kg |

| Teslimat kapsamı | 2 | Adet |

- Bunun için hidrolik ünite

- Sadece Xforce K yük hücresi ile birlikte