High Temperature Testing up to +2,000°C

Accessories for AllroundLine materials testing machines Download

Temperature range

- -80°C to +2,000°C

Components

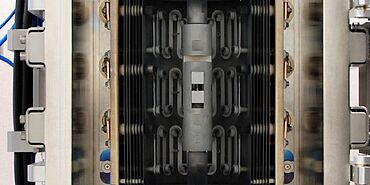

- Temperature chambers

- Furnaces

- Vacuum chambers

- Induction heating

- Temperature controller

- Specimen temperature measuring device

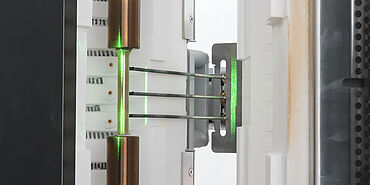

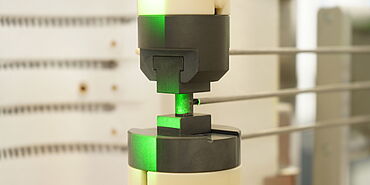

- Extensometers

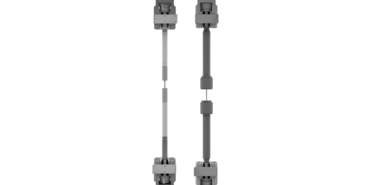

- Load strings

Advantages

- Precise temperatures

- Reliable strain measurement

- Secure specimen gripping

Optimally coordinated accessories are the foundation for reliable test results in high-temperature testing

To meet the many standards and customer requirements, ZwickRoell offers a large selection of modular high-temperature components for use with new and pre-owned AllroundLine testing machines, as well as for retrofitting machines from other manufacturers.

ZwickRoell offers complete solutions in a temperature range of -80°C up to +2,000°C for determination of the elastic behavior, resistance, and yield point of high-temperature resistant materials under high heat conditions. Not only the selection of the heating system to be used, but also reliable temperature control with suitable thermocouples, and a high-temperature load string with corresponding extensometer are essential for reliable results in high-temperature testing.