ASTM D1894 coefficient of friction plastic films

ASTM D1894 describes a standard test method for determination of the static and dynamic coefficients of friction (initial and sliding friction coefficients) of plastic film and sheeting when sliding them over themselves or other materials under specified test conditions.

The coefficients of friction provide information about the sliding properties of plastic films and play an important role in the packaging industry in particular and are relevant both in quality control during film production and in the development of film material for technical design. They also play an important role in EV battery testing in the form of separator film.

ASTM D1894 is not technically equivalent to its ISO counterpart ISO 8295, so the results of the two methods cannot be directly compared.

Objective & applications Coefficient of friction separator film Specimen & dimensions Running a test & test equipment Downloads FAQ Request a consultation

ASTM D1894 objective & applications

The determination of the coefficient of friction according to ASTM D1894 is particularly relevant for film materials that are further processed in packaging and printing machines. The static and dynamic coefficient of friction of plastic films in particular provides important information on processability and surface structure, which in turn is important for printability. Plastic films are widely used in the packaging industry, such as food and non-food packaging. They are also important components of more complex products such as batteries for electric vehicles.

Characteristic values / test results according to ASTM D1894

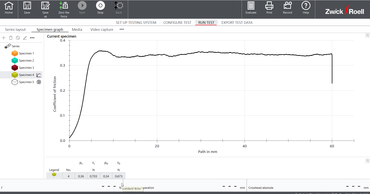

In the ASTM D1894 test, the coefficients of static and dynamic friction are measured. They indicate the force required to move two surfaces parallel to each other that are loaded with a weight. The lower the coefficient of friction, the easier the movement. The coefficients of friction are influenced by many factors. These include the materials of the surfaces, their roughness, the presence of lubricants, the ambient temperature and the humidity.

Coefficient of static friction: μs = As/B

Coefficient of dynamic friction: μk = Ak/B

| Abbreviation | Unit | Name | Short description |

| μs | Static coefficient of friction |

| |

| As | g | Static frictional force | As is the mass force in grams required to start the slide movement. |

| µk | Kinetic coefficient of friction |

| |

| Ak | N | Kinetic frictional force | Ak is the average mass force in grams recorded during the uniform movement of the carriage. |

| B | g | Mass of the carriage in grams |

ASTM D1894 specimens and dimensions

According to ASTM D1894, the specimen that is attached to the plane is defined with measurements of 250 mm x 130 mm (10 inches x 5 inches). The film specimen mounted on the sled must be cut to an approximately 120 mm (4.5 in.) square and shall not exceed a specimen thickness of 0.254 mm (according to standard terminology for films defined in ASTM D883).

ASTM D1894 test and test equipment

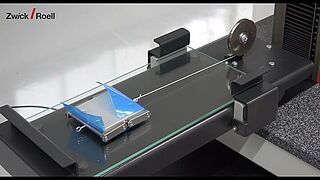

COF tester and test fixture:

- The determination of the coefficient of friction according to ASTM D1894 can be easily performed on a zwickiLine static testing machine using an additional ZwickRoell test fixture.

- The test fixture consists of a horizontal test table and a sled with known mass. The test fixture can be used to determine the frictional behavior between film and film.

Running a test:

- Film is clamped on the sled. A second film can be clamped to the stainless steel test table or onto the included glass plate, which is placed on the stainless steel table. The film pair is mounted between the table and the sled in such a way that there is full-surface support with evenly distributed pressure on the entire known surface area. This is accomplished by using a layer of felt.

- Whether the carriage is moved over the table or the movement is carried out by the table is irrelevant for the test.

Calculating the coefficient of friction:

- The coefficient of friction is represented as the quotient of the tensile force measured on the carriage and the contact force of the carriage that results from its own weight: Coefficient of friction μ = Fs/FD

- The static coefficient of friction (static friction) is calculated from the initial peak value of the tensile force on the sled, while the kinetic coefficient of friction (sliding friction) is calculated from the average value of the tensile force on the sled during a specified sliding distance.

Frictional properties of separator film in battery testing according to ASTM D1894

Separator film in a lithium-ion battery separates the anode and cathode from each other to prevent electrical short circuits. At the same time, the separator allows the flow of ionized charge carriers that are needed to close the circuit in an electrochemical cell.

In addition to ceramic separators and glass fiber nonwovens, polymer membranes are primarily used. Determination of the tensile strength and strain at break provides information about the integrity of the separator film under operational mechanical stress. While thicker separator film efficiently and safely prevents contact between the anode and cathode, thinner film makes it possible to reduce the weight of the battery and improve the energy density.

An additional relevant aspect is the behavior of the separator in relation to the coefficient of friction between electrode coating and separator. These characteristic values influence the performance of the cell and are particularly important for setting the production parameters in the winding processes. ZwickRoell enables you to not only run tests at ambient temperature, but also at operating temperatures in a range of -20 °C to +50 °C when adding a ZwickRoell temperature chamber. This ensures comprehensive characterization of the separator film under different conditions.

Since there are no specific test standards for EV batteries yet, ASTM D1894 is typically used as a substitute standard for characterizing their friction properties. These tests are also carried out in an electrolyte-wetted state in order to achieve realistic mechanical characteristics. Active involvement in the further development of these standards, especially for battery materials, ensures that ZwickRoell test methods will continue to meet all future requirements.

Take advantage of the leading testing software in materials testing

ZwickRoell’s testXpert testing software offers:

- Simple operation: start testing right away and be a testXpert while maintaining maximum safety.

- Reliable and efficient testing: benefit from reliable test results and maximum testing efficiency.

- Flexible integration: testXpert is the optimal solution for all of your applications and processes—simply put, a more effective workflow.

- Future-proof design: testing software for the entire life cycle, ready for your future test tasks!

Frequently asked questions about the determination of the coefficient of friction according to ASTM D1894

ISO 8295 and ASTM D1894 are two international standards for determining the coefficient of friction of plastic films. Among other things, the standards differentiate between the size and weight of the sled and the material with which the sled must be covered or sheathed. The size of the specimens also differs. In contrast to ASTM D1894, ISO 8295 specifies the use of a spring for the test.

The coefficients of friction (μ) static friction and dynamic friction are the main result of the test according to ASTM D1894. They indicate the force required to move two surfaces parallel to each other that are loaded with a weight. The lower the coefficient of friction, the easier the movement. The coefficients of friction are influenced by many factors. These include the materials of the surfaces, their roughness, the presence of lubricants, the ambient temperature and the humidity.

The formulas for calculating the static and dynamic coefficient of friction are as follows:

Coefficient of static friction: μs = As/B

Coefficient of dynamic friction: μk = Ak/B