Puncture test on films to ISO EN 14477

Puncture resistance is important when films are used as packaging material, for example, for food or parts with sharp edges. It is specified in standards ISO EN 14477, ASTM F1306.

Puncture test on films Puncture resistance of stretch wrap films Testing systems Downloads

Brief explanation of puncture test on films (Parker Ball-Point Test)

- Applying load using hard, sharp, or angular objects is important for packaging materials. Understanding puncture resistance is necessary if films are used as packaging material for food or parts with sharp edges.

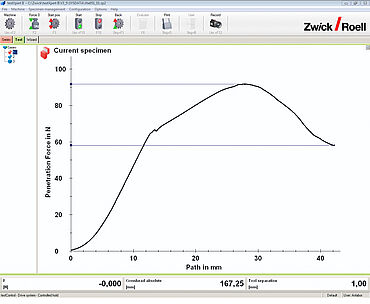

- The static puncture test to EN 14477 measures this behavior using a pointed tip with a diameter of 0.8 mm. This test is also known as the Parker Ball-Point Test.

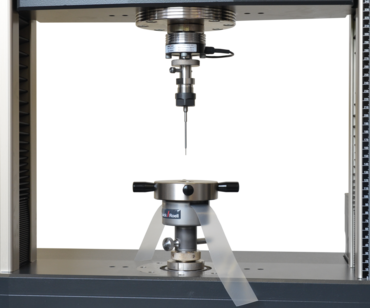

- In this test, a strip specimen is gripped in the lower specimen holder. It is punctured from above with an exchangeable probe to measure the maximum penetration force.

- ASTM F1306 describes a method with very similar objectives for measurement of flexible barrier films and laminates. It uses an indenter with a tip radius of 1.6 mm and a conical shaft with a 6° angle. The test is performed on a film strip, which is fastened over an opening with a 35 mm diameter.

To determine the puncture resistance on packaging films according to DIN EN 14477, ZwickRoell developed a special test device that provides a variety of benefits:

- Fast, easy, and reliable insertion of film strips.

- Endless strip specimens can be gripped quickly and securely.

- The test probe is mounted in a collet, which makes it easy to remove it.

- Round interchangeable jaw inserts (Vulkollan or O-ring against steel) for specimen gripping. A tightening nut is used to mechanically open and close the jaws and apply the gripping force.

Protrusion puncture resistance of stretch wrap film

This method, which is described in ASTM D5748, requires a larger radius indenter coated with PTFE to minimize friction. Throughout the deformation process, the film is significantly stretched before the indenter causes it to fail. Therefore, in addition to the puncture force, the deformation behavior of the film is also characterized in a multi-axial stress state.

Take advantage of the leading testing software in materials testing

ZwickRoell’s testXpert testing software offers:

- Simple operation: start testing right away and be a testXpert while maintaining maximum safety.

- Reliable and efficient testing: benefit from reliable test results and maximum testing efficiency.

- Flexible integration: testXpert is the optimal solution for all of your applications and processes—simply put, a more effective workflow.

- Future-proof design: testing software for the entire life cycle, ready for your future test tasks!