Paper Testing

Paper is a versatile material that is used in numerous industrial applications—from packaging and print products to paper for technical applications. Comprehensive material testing is essential to ensure the quality, resilience and safety of paper, cardboard and tissue products. International standards play a decisive role here, in particular the ISO and TAPPI standards, which set the global standard for paper testing procedures.

The ISO standards and TAPPI standards, such as ISO 1924 and TAPPI T 494 for determining tensile strength or ISO 9895 and TAPPI T 826 for determining the compressive strength of paper and cardboard, ensure that the test results are reproducible worldwide and meet the highest quality requirements. In addition, the ISO 12625 standard provides specific test methods for tissue testing to evaluate tear strength and other mechanical properties. TAPPI standards are particularly widespread in the North American paper industry and supplement the ISO standards with specific procedures that address regional requirements and technologies.

Find out more about our most important paper test methods and our testing machines for cardboard, tissue and paper testing below.

Paper & cardboard Tissue Testing machines and accessories Customer projects Downloads Request a consultation

Important test methods for paper and cardboard

| Short description | Standards |

|---|---|

| Paper & cardboard | Wet strength / wet tensile test |

|

| Paper & cardboard | Tensile test dry |

|

| Paper, cardboard & corrugated board | burst test |

|

| Paper | Corrugated paper | Corrugating medium test (CMT) |

|

| Paper & cardboard | Compressive strength / ring crush test (RCT) |

|

| Paper & cardboard | Compressive strength / short clamping test (SCT) |

|

| Paper | Zero-span tensile strength |

|

| Paper | Coefficient of friction |

|

| Paper & cardboard | Internal bond test / Z-direction tensile test |

|

| Paper, cardboard & corrugated board | Flexure test / stiffness under flexure (2-point, 3-point, 4-point) |

|

| Paper | Corrugated paper | Short-span compressive strength (S-test) |

|

| Cardboard | corrugated board | Flexure test / Quality of creasings |

|

| Cardboard | Corrugated board | Puncture test (LPET vs. PET) |

|

| Cardboard | Corrugated board | Flat crush test (FCT) |

|

| Cardboard | Corrugated board | Edge crush resistance (ECT) |

|

| Cardboard | Corrugated board | Box compression test / stacking test (BCT) |

|

Important test methods for tissue

| Short description | Standards |

|---|---|

| Paper | Tissue | Wet tensile strength |

|

| Paper | Tissue | Tensile test dry |

|

| Paper | Tissue | Burst strength / puncture test |

|

Paper testing equipment

The zwickiLine single-column universal testing machine is one of our up to 5 kN machines and is a powerful and flexible solution for a wide range of test methods in paper/cardboard and tissue testing. It is just as suitable for research and development as it is for ongoing quality assurance.

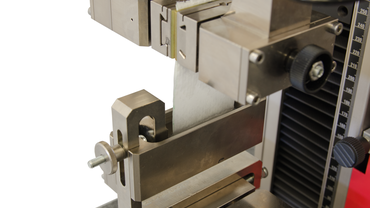

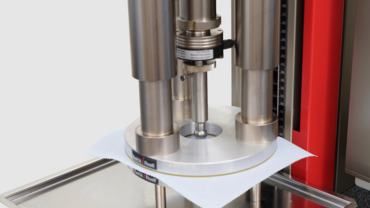

With our AllroundLine materials testing machine with four measuring axes, all relevant tests for predicting the compression strength of cardboard can be determined in a single machine, and a variety of tests can be performed on paper. With the equipment shown as an example in the image,

- the upper test area is used to run the ECT test, FCT test, CMT test and RCT test.

- The SCT test, the tensile test, and the 4-point flexure test (from left to right) are performed in the lower test area.

- Optionally expandable with additional slots, extensometers, safety doors and other accessories.

Interested? Feel free to contact us directly!

Contact us