Servohydraulic Testing Machines

Servohydraulic testing machines are used for static and dynamic testing of materials and components. Cyclic loads are generated in order to evaluate the behavior of materials and components over their service life. Servohydraulic testing systems are predominantly used to determine operational stability.

Due to the high energy that can be supplied by servohydraulic systems, piston speeds of up to 20 m/s can also be achieved, which are required for dynamic impact tests and crash investigations.

The extensive modularity of the ZwickRoell product portfolio enables us to provide individualized systems that are tailored to the customer’s needs in terms of force, stroke and performance.

Overview Operating principle Video Servohydraulic testing actuator FAQs Fatigue Testing Brochure

ZwickRoell offers servohydraulic testing machines for different types of tests:

Overview of servohydraulic testing machines

| Servohydraulic load frames | Servohydraulic compact systems | Single testing actuator | Torsional vibration | High speed | |

|---|---|---|---|---|---|

|  |  |  |  | |

| Load frames | Compact systems | Testing actuators | Torsion | High speed | |

| Max. force | 2,500 kN | 100 kN | 1,000 kN | 250 kN | 160 kN |

| Test speed | 1 m/s 1) | 1 m/s 1) | 1 m/s 1) | 1 m/s 1) | 20 m/s |

| Torsion | - | - | ✓ | ✓ | - |

| Power rating | Flexible | Fixed | Flexible | Flexible | Fixed |

| Common Tests |

|

|

|

|

|

1) Dependent on the hydraulic design

Operating principle of a servohydraulic testing machine

A servohydraulic materials testing machine consists of a unit that generates hydraulic power (hydraulic power unit), a hydraulic actuator and a measuring, control and regulation system.

The hydraulic power pack generates the pressure required to drive the actuator, and the flow rate is controlled by a servo valve. The actuator converts the hydraulic pressure into a mechanical movement and precisely controls the forces, torques, deformations and speeds during the testing process. The forces or deformations that occur are recorded by sensors and stored and displayed using the measurement, control and regulation system.

Servohydraulic testing actuator

The hydrostatic testing actuators are servohydraulic linear drives designed for maximum dynamics and service life. They are suitable as double-rod cylinders for dynamic and static tension-compression alternating loads.

Servohydraulic actuators are used as single testing actuators, for example on a clamping field for component testing, or as machine actuators in a test frame for materials testing.

The servohydraulic actuators are fitted with a servo valve. They convert hydraulic energy into a mechanical linear movement. The servo valve and accumulator are flange-mounted directly on the testing actuator, providing a high dynamic range. Nominal operating pressure options are 280 or 210 bar.

LH series hydrostatic testing actuators can be used in any desired orientation; in testing machines they are usually upright or suspended; in test benches they may also be horizontal.

Fatigue tests with servohydraulic testing machines

Servohydraulic testing machines are used to evaluate the fatigue strength of materials. Cyclic loads are applied to the material in order to determine its service life and its behavior under repeated stress. This is relevant for the development of components that are exposed to frequent stresses, such as in the aviation and automotive industries.

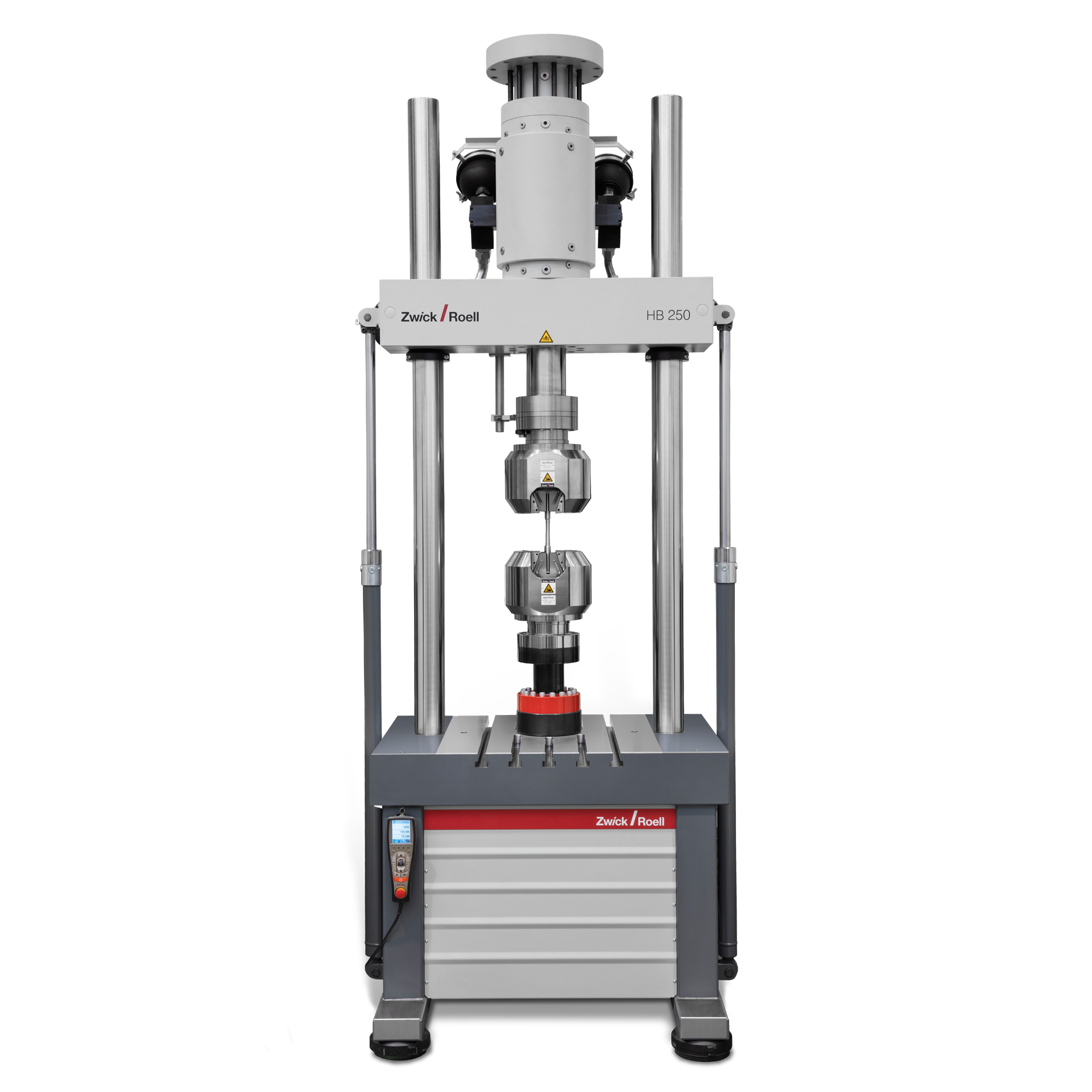

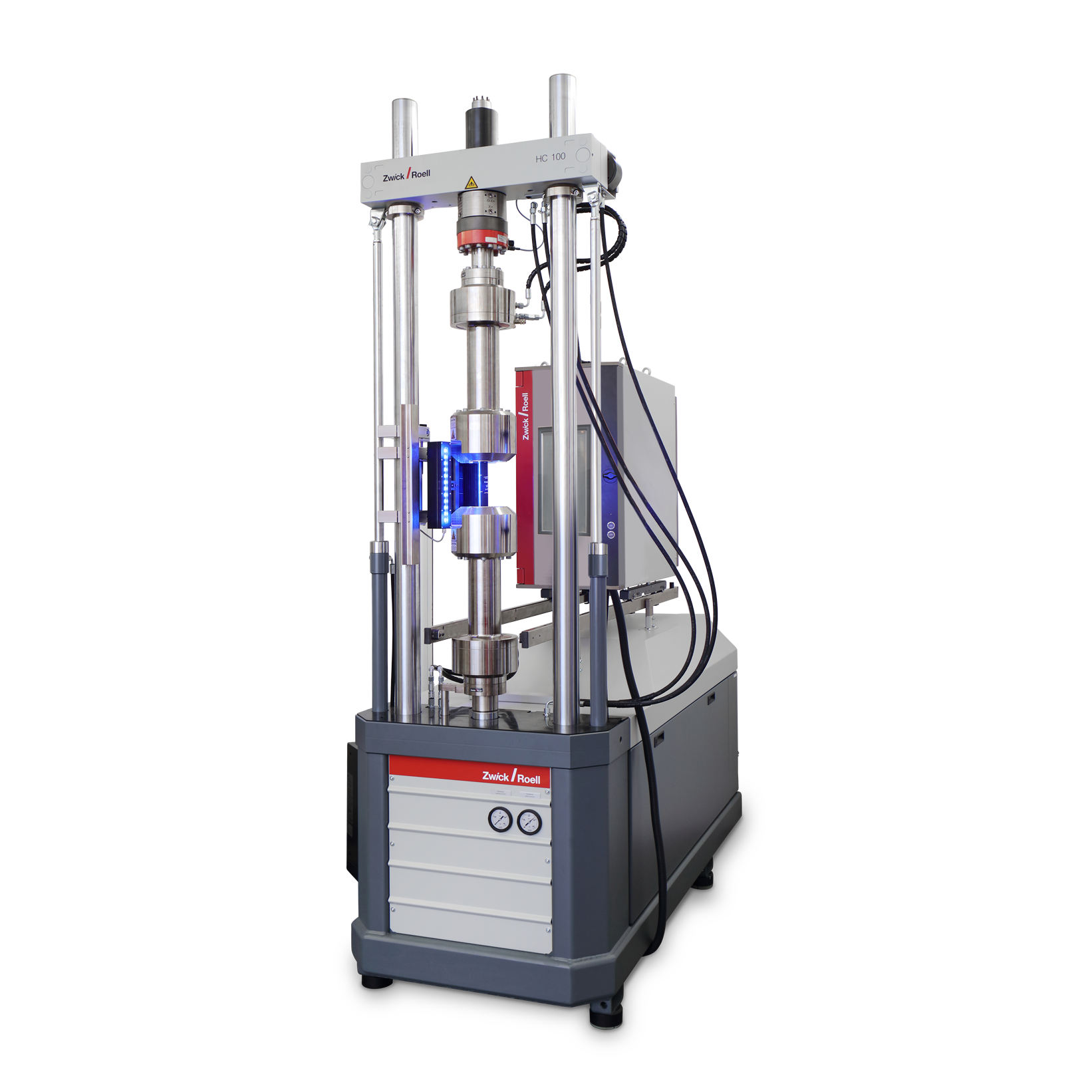

With characteristics such as high stiffness, ZwickRoell servohydraulic testing machine load frames have been specially designed to sustain the tough demands of fatigue tests. Depending on the test requirements and ergonomic demands in day-to-day operations, the testing actuator can either be mounted below (HA series) or above (HB and HC series) the test area.

HCT and HBT series servohydraulic testing machines are used to determine torsional vibration (tension/torsion tests). These machines have a torsion testing actuator mounted on the upper crosshead. The HC and HB series variant can be used for combined tensile, compression and torsion loading.

Fracture mechanics tests with servohydraulic testing machines

Servohydraulic testing machines are used in fracture mechanics tests both for vibration (crack formation) and for the subsequent tensile test. Reclamping the specimen is not necessary.

Fracture mechanics tests can also be performed with our vibrophore.

High-speed tests with servohydraulic testing machines

Servohydraulic high-speed testing machines are used in various fields including materials science, fracture mechanics, automotive safety, aerospace industry and ballistic research.

They make it possible to investigate the behavior of materials under extreme loads and high strain rates.

The high-speed testing machines from ZwickRoell are designed to provide a high level of stiffness and stability to meet the demands of high impulse peaks. They are ideal for puncture tests or high-speed tensile tests. The HTM series high-speed testing machines are ideally suited for the determination of material behavior under crash loading.

Servohydraulic testing machines - a modular system with many accessories

For the determination of high cycle fatigue strength, ZwickRoell can provide a customized modular system to cover all testing requirements, comprising actuators, hydraulic power packs, distribution units, dynamic testing machines and other accessories. With the testControl II unit, ZwickRoell additionally offers high-performance measurement and control electronics. Our testXpert testing software provides support during test set-up and performance of dynamic tests for the determination of material durability. Customized fatigue testing solutions are always available in addition to standardized products.

Would you like to know more about our wide range of accessories? Talk to our product experts!