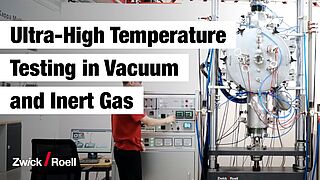

High-temperature testing systems

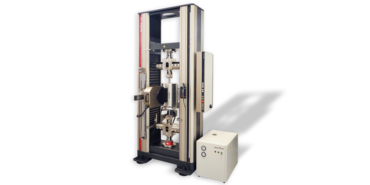

Temperature range from -80 °C to +2,000 °C- Metals

- Academia

- Aerospace

- Energy

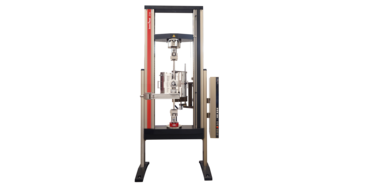

- 5 kN - 250 kN

- Tensile test

- Compression test

- Flexure test

- Strain-rate controlled test

- ISO 6892-2 A1

- EN 2002-002

- ASTM E21

The optimal solution for your universal testing at high temperature

ZwickRoell's high-temperature testing solutions are based on the proven load frame concept of the AllroundLine. The flexible and modular load frame design in conjunction with an array of high-temperature components enable the configuration of individual testing systems that are optimally matched to the testing requirements of our customers. ZwickRoell offers standard solutions in a temperature range of -80°C up to +1,600°C and customized testing solutions up to +2,000°C.

- A testing system for all quasi-static tests (tensile, compression and flexure tests)

- Wide temperature range: -80 °C to +1,600 °C with high-temperature furnace and temperature chamber

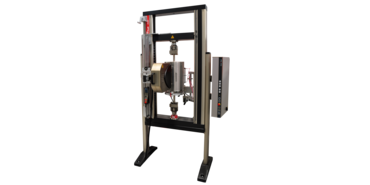

+200 °C to +2,000 °C with vacuum chamber - Precise measurement and standard-compliant specimen temperature control

- Wide selection of contact-type and non-contact extensometers for all applications in the entire temperature range

- Corresponding specimen grips for almost all materials (metals, plastics, composites, ...)

- Wide range of high-temperature accessories for customized system configurations

High-temperature application versatility

High-temperature testing systems for special requirements

ZwickRoell has many years of experience with project planning of customer-specific, high-temperature systems and specializes in complex requirements for high-temperature testing. Our engineers have the expertise necessary to configure the optimal system for your requirements based on our wide selection of system combinations and components.