ASTM D5379 | ASTM D7078 V-Notched Shear Tests on Composites

The ASTM D5379 and ASTM D7078 standards define standardized test methods for shear tests on composites, which are used to characterize the shear properties in the ply plane of unidirectional fiber composites and multidirectional 0°/90° fabrics.

Theoretically, each of the six possible shear planes can be tested separately. However, laminate manufacturing for measuring interlaminar shear strength characteristics is time consuming and therefore is typically not used.

Laminates with 45° layers cannot be measured using the ASTM D5379 and ASTM D7079 methods, as the normal stresses in the 45° layers would be very high and would distort the result. Test methods with ±45° laminate are described in ASTM D3518 (In plane shear test).

Objective & applications Specimens ASTM D5379 Iosipescu test ASTM D7078 Related test equipment Downloads Request a consultation

ASTM D5379 and ASTM D7078: objective and applications

Both ASTM D5379 and ASTM D7078 specify standardized test methods for measuring the shear properties of fiber-reinforced composites.

The range of applications is intended for the following types of laminates:

- Unidirectional laminates with fiber direction 0° or 90°

- Unidirectional laminates with same layer count in 0° and 90° fiber direction

- Fabric laminate with a weft direction of 0° or 90°

- Short fiber-filled plastics in which the fiber direction is randomly distributed

Specimens to ASTM D5379 and ASTM D7078

The specimens, which are defined in the test methods according to ASTM D5379 and ASTM D7078, differ in the size of the test specimen and the type of force application:

- In the V-notched rail shear test according to ASTM D7078, the test specimen is larger and is clamped to assess coarser fiber architectures.

- In the Iosipescu test according to ASTM D5379, a largely form-fit force transmission takes place.

The notch ensures a concentration of shear stresses in the narrowest cross-section, which ultimately leads to breakage. In this shear plane, the shear strains are measured with two strain gauges arranged at ± 45°.

Iosipescu test ASTM D5379

Applications:

- Since the specimen for the Iosipescu shear test according to ASTM D5379 is relatively small, this method is particularly suitable for measurements on unidirectional and 0°/90° fabrics where the fiber structure is relatively fine.

Testing to ASTM D5379:

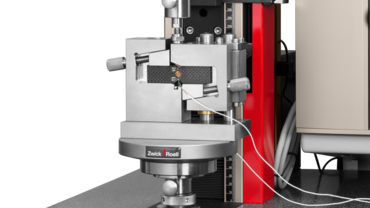

- The Iosipescu shearing device is guided in the longitudinal direction. It is placed on a compression platen or the crosshead of the testing system.

- A specimen notched on both sides is inserted in the shear test fixture. A zone of torque-free shear load emerges between the notches when a compression load is applied. The fibers must lie parallel or transverse in relation to the load direction. The shear strain is measured via two strain gauges that are applied at a 45° angle to the shear plane.

Characteristic values determined according to ASTM D5379:

- Shear behavior

- 0.2% shear stress

- Max. shear stress

- Secant shear module

ASTM D7078 V-notched rail shear test

Applications:

- The V-notched rail shear test according to ASTM D7078 uses a larger specimen compared to the Iosipescu method, which is clamped at the sides, allowing higher shear forces to be applied, meaning the method is suitable for measuring laminates with larger webbing.

Performing the test according to ASTM D7078:

- The specimen is provided with a V-notch for concentrating the shear plane. It is inserted laterally into the shear test device via friction locking. The shear strain is measured via two strain gauges that are applied at a 45° angle to the shear plane.

- The shear deformation is introduced via the two parts of the tool, which are moved in the tensile direction during the measurement. The standardized design of the tool does not provide for direct guidance, as is the case with the Iosipescu method.

- The tool must be precisely aligned using the adjustment gauges prior to the test. The ZwickRoell V-notched rail shear fixture compliant with ASTM D7078 ensures precise centering of the specimen with the provided, adjustable spacers. The alignment of the jaws to each other is ensured by the adjustability of the front and rear jaws.

Determined characteristic values / test results according to ASTM D7078:

- Shear behavior

- 0.2% shear stress

- Max. shear stress

- Secant shear module

Take advantage of the leading testing software in materials testing

ZwickRoell’s testXpert testing software offers:

- Simple operation: start testing right away and be a testXpert while maintaining maximum safety.

- Reliable and efficient testing: benefit from reliable test results and maximum testing efficiency.

- Flexible integration: testXpert is the optimal solution for all of your applications and processes—simply put, a more effective workflow.

- Future-proof design: testing software for the entire life cycle, ready for your future test tasks!