Tensile tests on plastics at low, elevated or high strain rates

The measurement of stress-strain curves using the tensile test on plastics under high strain rate conditions provides data for crash simulations, for example in vehicle construction.

Objective & standards Test / test equipment requirements Testing systems Plastics brochure

Standards and objectives of high-speed tensile tests to SAE J2749, ISO 18989, ISO 18872, VDA Recommendation 287

The measurement of stress-strain curves under high strain rates provides design data for crash simulations, for example in vehicle construction. An international standard for variable strain rates covering static and high-speed tensile tests is currently under development.

- SAE J 2749 defines the test and requirements for the test equipment in general form

- ISO 18989 is a draft of a test standard specifying a procedure for tensile tests with variable strain rates in the range from static to more than 150 s-1. This project is based on:

- VDA 287, a recommendation of the German Association of the Automotive Industry (VDA).

- ISO 22183 defines quality criteria for the dynamic behavior of force measurement and therefore enables a uniform evaluation of measuring graphs in terms of their quality

- ISO 18872 is more of a theoretical approach with general definitions and a procedure for extrapolation of results at higher strain rates. Use of the standard is limited.

Tensile behavior under high strain rates is measured on specified specimens and under known conditions at pull-off speeds ranging from static testing to about 5 m/s. This allows strain rates of up to 200 1/s to be achieved on specimens Type 3 according to ISO 8256.

Test requirements

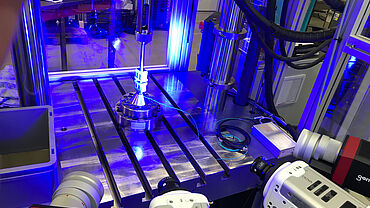

For these tests, hydraulic high-speed tensile testing machines are normally used, in which a piston is briefly accelerated to the required test speed by means of hydraulic energy stored in accumulators, are normally used. This machine type makes is possible to measure at both low and high speeds.

Tests in a speed range above approx. 1.5 m/s can also be performed using drop weight testers specifically adapted for plastics testing. The test arrangement in this case is similar to the tensile impact test, in which the specimen is firmly gripped on one side and a yoke is fitted on the opposite side, which transmits the movement of the drop weight to the specimen. At lower speeds it does not make sense to test with a drop weight tester due to the low drop heights and very large drop masses that would be required.

To ensure validity of the test, it is essential to use a suitable extensometer or displacement measuring system than can determine both the speed of the pulling grip or the yoke and the deformation of the specimen with high resolution and sufficient speed. Normally, fast camera systems with 2D DIC evaluation are used for this purpose.

The force is measured via a stiff and low-mass measuring system, which in addition to good measurement accuracy and a more than 200 kHz measured value acquisition, must have the highest possible natural mechanical frequency. The period of this natural oscillation must be at least a factor of 8 to 10 less than the measurement duration up to the relevant test event to be measured.

In theory, movement of the pulling grip should accelerate from zero to the desired pull-off speed without time delay, and then remain constant. To get as close as possible to this ideal scenario, an additional low-mass element is used between the piston and the specimen grip, which is referred to as the lost motion bar. This element, together with the connected specimen grip, determines the dynamic sequence of the deformation process and is therefore of significant importance for the assignment of the stress strain curve to the required third axis, the strain rate.

The tests are usually performed in a normal climate according to standard ISO 291. If the high-speed tensile behavior of plastics is to be tested in a wide temperature range, we have temperature chambers available that can be installed in the test area of the high-speed testing machine.