Захваты и приспособления для испытаний материалов

Фиксация образца в подходящих захватах и испытательных приспособлениях является элементарным условием для надежного проведения испытаний с получением точных результатов.

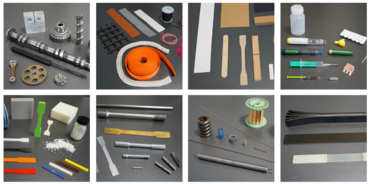

Благодаря широкому спектру захватов различных конструкций, диапазонов усилий испытаний и температур фирма ZwickRoell не только охватывает обширные области применения (например, испытания пластмасс, композитов и металлов), но также предлагает современные и соответствующие стандартам решения для самых разных материалов и форм образцов в таких отраслях, как медицинская техника и фармацевтика, текстильная промышленность, продукты питания и упаковка, а также бумага и картон.

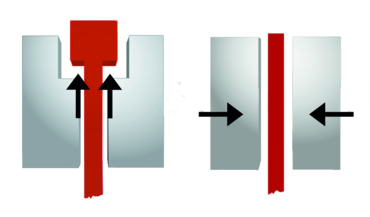

Самым популярным испытанием является испытание на растяжение. Оно предъявляет особенно высокие требования к захватам, поскольку усилие испытания направлено не перпендикулярно образцу, как при испытаниях на сжатие и изгиб, а прямо противоположно. Поэтому образец всегда нуждается в соответствующих выступах на своих концах (головках) для передачи испытательного усилия в захваты.

Также фирма ZwickRoell предлагает широкий спектр захватов и приспособлений для испытаний на сжатие и изгиб.

Захваты для испытаний на растяжение Испытательные приспособления Критерии выбора

Критерии выбора захватов для испытаний на растяжение

| Захваты (принцип функционирования) | Номиналы (макс. усилие испытания) | Диапазон температуры применения | Основные области применения | |

|---|---|---|---|---|

| Винтовые захваты | 0,02-50 кН | -70°…+250° | пластиковые пленки, образцы-полоски, ленты, тросы, шнуры, лопатки, металлические листы и тонкие листовые металлы, проволока, тонкая проволока, трубы, плоские и круглые образцы, текстильные волокна, нити, нетканые материалы, конвейерные ленты, ремни |

| Пружинно-винтовые захваты | 0,02-0,05 кН | -15°…+80° | пластиковые пленки, проволока, тонкая проволока, текстильные волокна, тонкие нити, эластичная пряжа, чувствительные к зажиму материалы |

| Пневматические захваты | 0,02-100 кН | -70°…+250° | пластиковые пленки, образцы-полоски, ленты, монофиламенты, тросы, шнуры, лопатки, металлические листы и тонкие листовые металлы, проволока, тонкая проволока, трубы, плоские и круглые образцы, нити, нетканые материалы, общие и технические ткани, канаты, конвейерные ленты, ремни |

| Гидравлические захваты | 10-2.500 кН | -70°…+250° | пластиковые пленки, монофиламенты, лопатки, металлические листы и тонкие листовые металлы, проволока, тонкая проволока, трубы, плоские и круглые образцы, профили, нетканые материалы, общие и технические ткани, геотекстильные изделия, конвейерные ленты, ремни |

| Клиновые захваты | 2,5-600 кН | -70°…+250° | монофиламенты, лопатки, металлические листы и тонкие листовые металлы, тонкая проволока, ленты, трубы, плоские и круглые образцы, конвейерные ленты, ремни |

| Клино-винтовой захват | 0,5-250 кН | -40°…+250° | пластиковые лопатки, металлические листы и тонкие листовые металлы, тонкая проволока, ленты, трубы, плоские и круглые образцы, конвейерные ленты, ремни |

| Цанговые захваты | 0,5-10 кН | -40°…+250° | пластиковые пленки, образцы-полоски, металлические листы и тонкие листовые металлы, плоские образцы, конвейерные ленты, ремни |

| Шарнирные захваты | 0,3-2,5 кН | -15°…+80° | пластиковые пленки, образцы-полоски, нетканые материалы |

| Вальцевые захваты | 2,5-250 кН | -70°…+250° | ленты и ремни |

| Шарнирные захваты | 0,5-20 кН | +10…35° | плоские образцы, ремни, ленты, шинные корды, проволока, элементарное волокно и штапельная пряжа, нити низкой тонины, крученая пряжа, мультифиламенты, металлическое галево, проволока, стальные шинные корды |

Кроме того, фирма ZwickRoell предлагает различные специальные захваты и аксессуары:

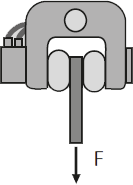

Винтовые захваты

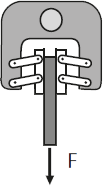

Винтовые захваты являются зажимными приспособлениями с односторонним закрытием. Открытие и закрытие, а также приложение усилия зажима перед испытанием осуществляется посредством шпинделя. При винтовых захватах усилие зажима прикладывается вручную или с помощью электромотора. Их можно использовать для уменьшенных и увеличенных испытательных усилий (от 20 Н до 50 кН) и тонких образцов (например, тонкая проволока, волокна и пленки).

Максимальная ширина открытия составляет 31 мм (может варьироваться в зависимости от губок). Стандартные испытания можно проводить при температурах от -70 °C до +250 °C. Усилие зажима зависит от момента затяжки винта и упругости захвата.

Преимущества и признаки винтовых захватов:

- Простое и быстрое проведение испытаний даже составных (несимметричных) образцов, благодаря возможности перестановки ответной губки

- Диапазон измерения датчика силы можно широко использовать, благодаря легкой конструкции захватов.

- При смене конфигурации испытания можно быстро и легко заменить губки без использования инструментов. При этом центровка губок проводится автоматически.

- Надежное удержание образца достигается даже при низких усилиях с помощью шарикоподшипников.

- Большая ширина открытия гарантирует широкий диапазон применения.

- Надежное удержание образца гарантируется даже при смене испытаний. Благодаря большому выбору губок, захваты можно оптимально согласовать с Вашими испытаниями.

- Даже уменьшающиеся образцы надежно удерживаются, благодаря автоматическому дожиму посредством пакета дисковых пружин.

- Захватами легко управлять в термокамере; благодаря их малой массе, быстро достигается температура испытания.

- Точные результаты испытаний при одновременно высокой тактности, благодаря загрузки образца по центу с помощью легко настраиваемого ограничителя.

- Быстрые и простые загрузка и зажим образца, благодаря эргономической и открытой форме.

Загрузки, винтовые захваты

- Информация о продукте: винтовые захваты, Fmax 20 Н PDF 825 KB

- Информация о продукте: винтовые захваты, Fmax 200 Н PDF 132 KB

- Информация о продукте: винтовые захваты, Fmax 200 Н PDF 995 KB

- Информация о продукте: винтовые захваты, Fmax 500 Н PDF 147 KB

- Информация о продукте: винтовые захваты, Fmax 1 кН PDF 493 KB

- Информация о продукте: винтовые захваты, Fmax 2,5 кН PDF 2 MB

- Информация о продукте: винтовые захваты, Fmax 5 кН / 10 кН PDF 485 KB

- Информация о продукте: захваты для изоляционных материалов, Fmax 10 кН PDF 860 KB

- Информация о продукте: винтовые захваты, Fmax 20 кН PDF 208 KB

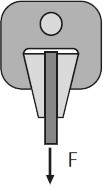

Пружинно-винтовые захваты

Пружинно-винтовые захваты особенно подходят для испытаний с очень малыми усилиями (Fmax от 20 Н до 50 Н) geeignet. Его массовая сила настолько мала по сравнению с номиналом установленного датчика силы, что диапазон силоизмерения не ограничен. Усилие зажима создает пружина с предварительно настраиваемым усилием натяжения. Таким образом, можно испытывать чувствительные к прижиму образцы с одинаковым зажимным усилием.

Преимущества и признаки пружинно-винтовых захватов

- Точные результаты испытаний при одновременно высокой тактности, благодаря вспомогательному центрирующему механизму для укладки проводов и нитей

- Постоянное усилие зажима позволяет получать воспроизводимые результаты испытаний.

- Быстрые и простые загрузка и зажим образца, благодаря эргономической и открытой форме

- Губки подвижны, их можно точно адаптировать к образцу.

- Диапазон измерения датчика силы можно использовать оптимально, благодаря легкой конструкции захватов.

- При смене испытания можно быстро и легко заменить губки без использования инструментов. При этом центровка губок проводится автоматически (только при Fmax 20 Н)

Пневматические захваты

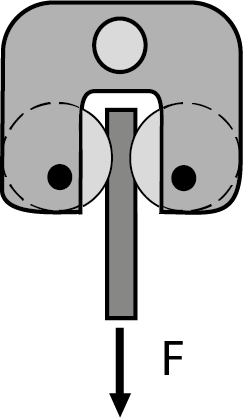

Пневматические захваты используются преимущественно там, где необходимо испытывать различные, прежде всего, чувствительные к зажиму материалы с низкими затратами на переоснащение. Создаваемое пневматическим цилиндром усилие прижима прикладывается к губкам напрямую или через систему рычагов.

Признаки всех пневматических захватов:

- Благодаря разделению усилия растяжения и усилия зажима, обеспечивается постоянное усилие зажима в течение всего процесса испытания. Благодаря постоянному пневматическому давлению, усилие зажима поддерживается равномерным даже при испытаниях уменьшающихся образцов.

- Прикладываемое к образцу давление прижима воспроизводимо.

- Возможен надежный зажим чувствительных образцов, благодаря адаптации пневматического давления предотвращается разрушение образца в зажимах.

- Нагружение растяжения может прикладываться статически или с нарастанием. В зависимости от типа захватов можно также проводить испытания на сжатие и с переменным нагружением.

- Приоритетным типом нагружения является растяжение. Оно прикладываться статически или с нарастанием. В зависимости от типа захватов можно также проводить испытания на сжатие и с переменным нагружением.

- Принцип конструкции обеспечивает свободный доступ к зоне зажима.

- При больших захватах можно, не снимая их, адаптировать малые датчики силы, захваты и прочие приспособления, экономя время.

- Существует большое разнообразие губок в плане материала, поверхности и размера площади зажима.

- Пневматические захваты представляют собой более экономичную альтернативу захватам гидравлическим.

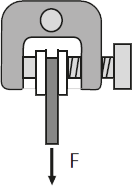

Пневматические захваты с односторонним закрытием

Пневматические захваты с односторонним закрытием можно использовать как для симметричного, так и для несимметричного зажима образцов (например, для испытаний на сдвиг). Открытие и закрытие, а также приложение усилия зажима перед испытанием осуществляется пневматически посредством рычажного клапана на захвате. Изменение давления закрытия захвата не возможно. Дополнительный пневматический модуль управления не требуется, однако его можно использовать в качестве альтернативы. Ответную губку можно плавно регулировать. Они подходят для испытательных усилий от 20 Н до 30 кН.

Преимущества пневматических захватов с односторонним закрытием

- Даже деформируемые образцы удерживаются надежно, благодаря постоянному пневматическому давлению.

- Постоянное усилие зажима позволяет получать воспроизводимые результаты испытаний.

- Высокая интенсивность проведения испытаний, благодаря быстрой установке и точной центровке образца посредством вспомогательного загрузочного механизма и направляющей канавки.

- Простая и быстрая смена образцов, благодаря управлению захватами посредством рычага.

- Простое и быстрое проведение испытаний даже составных (несимметричных) образцов, благодаря возможности перестановки ответной губки.

- Быстрые и простые загрузка и зажим образца, благодаря эргономической и открытой форме.

- Специальный соединительный модуль для применения в термокамере со встроенной системой подачи нагнетаемого воздуха. Поддон для конденсата обеспечивает отдельный вывод конденсата из рабочей зоны. Ответную губку можно регулировать плавно или ступенчато.

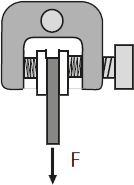

Пневматические захваты с двухсторонним закрытием

Пневматические захваты с двухсторонним закрытием закрываются всегда симметрично относительно оси растяжения. Благодаря этому нет необходимости в настройке толщины. Губки фиксируются штифтом с резьбой. Их можно менять без использования инструментов. Наличие дополнительного пневматического модуля управления не требуется. Захваты плавно открываются и закрываются посредством рычажного клапана. Это предлагает преимущества в плане регулирования обнуления усилия. Пневматическое давление зажима на захвате изменить нельзя. Это позволяет сделать только дополнительный клапан ограничения давления.

Преимущества пневматических захватов с двухсторонним закрытием

- Симметричное закрытие захвата экономит время на настройку при переменной толщине образцов и обеспечивает точный зажим образца на оси испытания.

- При смене испытания можно быстро и легко заменить губки без использования инструментов. При этом центровка губок проводится автоматически.

- Постоянное усилие зажима позволяет получать воспроизводимые результаты испытаний.

- Даже деформируемые образцы удерживаются надежно, благодаря постоянному пневматическому давлению.

- Простая и быстрая смена образцов, благодаря управлению захватами посредством рычага.

- Быстрые и простые загрузка и зажим образца, благодаря эргономической и открытой форме.

- Усилие зажима всегда постоянно, оно не зависит от усилия испытания. Поэтому захваты очень хорошо подходят для чувствительных к зажиму материалов или для высокой интенсивности проведения испытаний.

- Закрытие всегда происходит симметрично относительно оси растяжения. Благодаря этому образец зажимается точно по оси. В настройке по ширине образца нет необходимости.

Пневматические - захваты, «корпус с клиньями»

При пневматических захватах на первый план выходит быстрый, воспроизводимый и, прежде, всего, параллельный зажим. Полное усилие закрытия доступно с самого начала, так что неподвижные губки переносят скорость испытания прямо на образец. У пневматических захватов серии "корпус с клиньями" позиция губок при зажиме образца остается постоянной в направлении испытания. Благодаря этому зажимная длина не зависит от толщины образца.

Для применения в термокамере просто используют удлинители. Пневматический цилиндр расположен вне камеры.

Преимущества пневматических захватов типа «корпус с клиньями»:

- Даже при чувствительных образцах или малой зажимной длине эти симметричные захваты гарантируют оптимальный зажим.

- Зажимная длина для определения точной номинальной деформации не зависит от диаметра образца. Время настройки сведено к минимуму.

- Малый вес и компактная конструкция облегчают обращение с захватами, обеспечивают краткое время нагрева и охлаждения в термокамере и большие пути перемещения

- Абсолютно надежное удержание легко выскальзывающих образцов с самого начала испытания.

Пневматические захваты для термокамеры

Пневматические захваты также специально разработаны для применения в термокамерах. Они располагают специальным соединительным модулем для применения в термокамере со встроенной системой подачи нагнетаемого воздуха. Поддон для конденсата обеспечивает отдельный вывод конденсата из рабочей зоны. Ответную губку можно регулировать плавно или ступенчато.

Высота соединительного модуля зависит от используемой испытательной системы и термокамеры, а также обусловленного образцами хода в термокамере. Поэтому она определяется индивидуально.

Пневматический модуль управления

Пневматический модуль управления обеспечивает надежную эксплуатацию согласно всем стандартам и универсальные возможности управления:

- Клавиши непосредственно на модуле управления

- Ножное управление с помощью педального модуля

- Эргономичный пульт ДУ с дисплеем

- Привязка к программному обеспечению testXpert

Пневматический модуль управления можно комбинировать со всеми вариантами пневматических захватов и нагружающими рамами из серийной производственной программы фирмы ZwickRoell. Он подходит для образцов нестабильной формы, чувствительных к зажиму и склонных к скольжению даже при меняющейся толщине, а также для высокой интенсивности проведения испытаний и при частой смене материала образцов.

Загрузки, пневматические захваты

- Информация о продукте: Пневматические захваты, Fmax 50 Н / 200 Н PDF 511 KB

- Информация о продукте: пневматические захваты, Fmax 200 Н PDF 485 KB

- Информация о продукте: Пневматические захваты, Fmax 500 Н PDF 726 KB

- Информация о продукте: Пневматические захваты, Fmax 1 кН, встроенный управляющий клапан PDF 326 KB

- Информация о продукте: пневматические захваты, Fmax 1 кН PDF 3 MB

- Информация о продукте: пневматические захваты, Fmax 2,5 кН PDF 3 MB

- Информация о продукте: пневматические захваты, Fmax 5 кН / 10 кН / 30 кН PDF 387 KB

- Информация о продукте: пневматические захваты, Fmax 20 Н PDF 596 KB

- Информация о продукте: пневматические захваты, Fmax 200 Н / 1 кН PDF 1 MB

- Информация о продукте: пневматические захваты, Fmax 2,5 кН PDF 557 KB

- Информация о продукте: пневматические захваты, Fmax 10 кН / 20 кН PDF 805 KB

- Информация о продукте: Пневматические захваты, Fmax 50 кН / 100 кН PDF 661 KB

- Информация о продукте: Пневматические захваты «корпус с клиньями», Fmax 10 кН / 20 кН PDF 2 MB

- Информация о продукте: Пневматические захваты для термокамер, Fmax 200 Н / 2,5 кН PDF 257 KB

- Информация о продукте: Пневматические захваты для термокамер, Fmax 1 кН PDF 604 KB

- Информация о продукте: пневматические захваты для термокамер, Fmax 10 кН / 20 кН PDF 3 MB

- Информация о продукте: Пневматический модуль управления PDF 225 KB

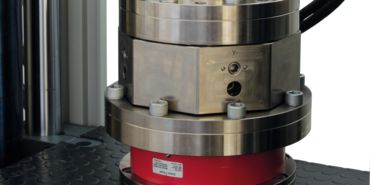

Гидравлические захваты

Гидравлические захваты используются, прежде всего, там, где необходимо усилие испытания от 50 кН, а также высокое усилие зажима (Fmax от 10 кН до 2000 кН). Давление прижима точно воспроизводимо.

Принцип работы гидравлического захвата

В гидростанции настраивается давление масла в соответствии с необходимым давлением закрытия захватов. Модуль управления регулирует процесс закрытия и открытия для верхнего и нижнего захвата по отдельности.

При универсальной гидростанции процесс закрытия , кроме того, делится на фазу закрытия и фазу зажима. В фазе закрытия сначала зажимается верхний конец образца (по причинам безопасности). Затем в фазе зажима прикладывается полное усилие зажима, величина которого ориентирована на ожидаемое растягивающее усилие.

Цилиндры двухстороннего действия

Все гидравлические захваты оснащены цилиндрами двухстороннего действия. Это означает, что даже открытие захвата происходит не под воздействием пружин, а гидравлически. Давление закрытия и открытия можно соответственно настраивать.

По сравнению с цилиндрами одностороннего действия, в которых открытие происходит под воздействием пружин, цилиндры двухстороннего действия обладают тем преимуществом, что захваты всегда открываются безопасно. Даже в том случае, если образец перекошен или заклинен. Кроме того, нет необходимости в полном ходе открытия, т.к. процесс открытия можно прервать в любой момент, нажав на кнопку "Стоп". Ход открытия можно настраивать в зависимости от толщины. Это экономит время испытания (особенно тонких образцов) и снижает риск защемления рук

Гидравлические захваты с односторонним закрытием

Гидравлические захваты с односторонним закрытием можно использовать как для симметричного, так и для несимметричного зажима образцов (например, для испытаний на сдвиг). Настройка толщины образца проводится с помощью маховика.

Существует модель гидравлических захватов с односторонним закрытием с тандемным цилиндром для равномерного приложения усилия к образцу (особенно подходит для испытаний ткани, текстиля и геотекстиля).

Преимущества и признаки гидравлических захватов с односторонним закрытием

- Гидравлические захваты обладают эксцентрической поршневой формой с большим ходом поршней. Это обеспечивает крайне глубокое положение зажимных поверхностей и большую ширину открытия.

- Благодаря выравниванию губок, захватов и поршней можно зажимать даже короткие образцы.

- Оптимальный зажим чувствительных материалов обеспечивается регламентированным приложением усилия.

- Давление прижима точно воспроизводимо.

- Захваты можно устанавливать в трех различных угловых положениях (0°, 45° и 90°) относительно испытательной системы.

- Проделанные в нижней части корпуса пазы служат креплением для шиберной системы. Это позволяет осуществлять адаптацию малых датчиков силы, захватов и прочих приспособлений (исключение: гидравлические захваты тип 8392, Fmax 10 кН).

- Призматические губки (губки с V-образным пазом) можно проворачивать и использовать двояко: для круглых и для плоских образцов, или для круглых образцов с различными диаметрами (при губках с крестообразно расположенными V-образными пазами).

- Открытие и закрытие верхнего и нижнего захвата можно проводить по отдельности или совместно с помощью пульта ДУ или через ПК.

- Надежное удерживание образца обеспечивается индивидуальным настраиваемым соотношением между усилием зажима и усилием растяжения (при максимальном усилии растяжения требуется примерно 2-кратное усилие зажима).

- Конструкция гидравлических захватов обеспечивает оптимальную подачу образцов.

- При ручной подаче образцов четкий вертикальный зажим обеспечивает регулируемый упор со шкалой.

- Для облегчения центрирования образца можно использовать ограничитель.

- По причинам безопасности для загрузки образцов можно использовать щипцы.

Гидравлические захваты с двухсторонним закрытием

Гидравлические захваты с двухсторонним закрытием закрываются всегда симметрично относительно оси растяжения. Благодаря этому, образец зажимается точно по оси. В настройке толщины нет необходимости.

- Постоянное усилие зажима позволяет получать воспроизводимые результаты испытаний.

- Оптимальное сочетание гидростанции, блока электроники и программного обеспечения гарантирует получение надежных результатов испытаний. В процессе зажима система регулирования обнуления усилия предотвращает воздействие на образец нежелательных усилий.

- Экономьте время, быстро и просто адаптируя малые захваты и испытательные приспособления к большим захватам посредством шиберной системы. Точное выравнивание гарантирует получение надежных результатов испытаний.

- Симметричное закрытие захвата экономит время на настройку при переменной толщине образцов и обеспечивает точный зажим образца на оси испытания.

- Благодаря специальной конструкции захватов, можно зажимать даже короткие образцы.

- Быстрые и простые загрузка и зажим образца, благодаря эргономической и открытой форме

- Получение точных результатов достигается с помощью настраиваемого ограничителя образца даже при высокой интенсивности проведения испытаний.

Гидравлические захваты, «корпус с клиньями»

Гидравлический захват «корпус с клиньями» с двухсторонним закрытием используется для симметричного зажима. Принудительно перемещаемые губки воспроизводимо зажимают образец. Благодаря симметричной конструкции и высокой жесткости корпуса, захваты оптимально подходят для испытаний, при которых предъявляются высокие требования к выравниванию образца на оси испытания.

Захваты представляют собой симметрично закрываемые клиновые зажимные приспособления, закрываемые и открываемые гидравлически. При этом посредством гидравлики вертикально перемещается только внешний корпус. Посредством движения корпуса губки (клинья) перемещаются в горизонтальной плоскости параллельно друг к другу.

Преимущества гидравлических захватов «корпус с клиньями»

- Постоянное усилие зажима позволяет получать воспроизводимые результаты испытаний.

- Оптимальное сочетание гидростанции, блока электроники и программного обеспечения гарантирует получение надежных результатов испытаний. В процессе зажима система регулирования обнуления усилия предотвращает воздействие на образец нежелательных усилий.

- Благодаря своей симметричной конструкции захваты подходят для решения задач, требующих точного выравнивания (например, для испытаний образцов, чувствительных к поперечному растяжению).

- Благодаря параллельному принципу зажима (отсутствие дифференциального перемещения губок) скорость испытания передается непосредственно на образец.

- Быстрые и простые загрузка и зажим образца, благодаря эргономической и открытой форме

- Получение точных результатов достигается с помощью настраиваемого ограничителя образца даже при высокой интенсивности проведения испытаний.

- При испытаниях, например, композитных образцов преимуществом захватов является простота очистки.

- Гидравлические захваты «корпус с клиньями» также подходят для использования в сервогидравлических испытательных машинах, они отличаются высокой степенью комфорта в управлении. В сервогидравлических испытательных машинах они подсоединяются к источнику подачи нагнетаемого масла. При использовании в статических испытательных машинах необходима малая гидростанция.

Гидростанции GripControl

Плавный зажим, благодаря гидростанции GripControl

- Гидростанции GripControl предназначены для гидравлических захватов и приспособлений фирмы ZwickRoell номиналом до 250 кН.

- Для всех типов гидростанций характерен высокий стандарт безопасности. Это подразумевает, кроме всего прочего, контур аварийного выключения и шаговый режим.

- Благодаря компактному дизайну, гидростанцию можно поставить даже под стол. Дополнительным отличием гидростанций являются очень высокая степень доступности, удобная в обслуживании конструкция и большой срок службы.

Загрузки, гидравлические захваты

- Информация о продукте: гидравлические захваты, Fmax 50 кН PDF 425 KB

- Информация о продукте: гидравлические захваты, Fmax 100 кН / 250 кН PDF 638 KB

- Информация о продукте: гидравлические захваты с большой шириной открытия, Fmax 10 кН PDF 604 KB

- Информация о продукте: гидравлические захваты для геотекстильных изделий, Fmax 50 кН / 100 кН / 250 кН PDF 525 KB

- Информация о продукте: гидравлические захваты для малых зажимных длин, Fmax 50 кН / 70 кН PDF 376 KB

- Информация о продукте: гидравлические захваты для малой зажимной длины, Fmax 150 кН / 250 кН PDF 327 KB

- Информация о продукте: гидравлические захваты до 2500 кН PDF 280 KB

- Информация о продукте: гидравлические захваты „корпус с клиньями“, Fmax 100 кН PDF 608 KB

- Информация о продукте: гидравлические захваты „корпус с клиньями“, Fmax 250 кН PDF 834 KB

- Информация о продукте: гидравлические клиновые захваты на 25 кН для сервогидравлики PDF 360 KB

- Информация о продукте: гидравлические клиновые захваты на 100 кН для сервогидравлики PDF 616 KB

- Информация о продукте: гидравлические клиновые захваты на 250 кН для сервогидравлики PDF 349 KB

- Информация о продукте: гидростанция GripControl PDF 369 KB

- Информация о продукте: универсальная гидростанция PDF 288 KB

Клиновые захваты

Клиновые захваты - захваты с симметричным закрытием. Они состоят из массивного корпуса со сменными губками или неподвижными губками, а также управляющего модуля для открытия и закрытия захвата. Открытие и закрытие, а также приложение усилия закрытия перед испытанием осуществляется посредством рычага. Они обеспечивают свободный доступ к зоне зажима.

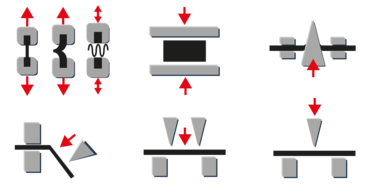

Различаются два принципа функционирования:

- "корпус с клиньями" (его также называют BoW или Body-over-Wedge)

- "рычаг"

Загрузки, клиновые захваты

- Информация о продукте: клиновые захваты, Fmax 2,5 кН / 5 кН PDF 161 KB

- Информация о продукте: клиновые захваты, Fmax 10 кН / 20 кН PDF 713 KB

- Информация о продукте: клиновые захваты, Fmax 10 кН / 50 кН PDF 230 KB

- Информация о продукте: клиновые захваты „корпус с клиньями“, Fmax 10 кН PDF 690 KB

- Информация о продукте: клиновые захваты, Fmax 30 кН / 50 кН PDF 295 KB

- Информация о продукте: клиновые захваты „корпус с клиньями“, Fmax 50 кН PDF 427 KB

- Информация о продукте: клиновые захваты, Fmax 100 кН PDF 349 KB

- Информация о продукте: клиновые захваты „корпус с клиньями“, Fmax 100 кН PDF 451 KB

- Информация о продукте: клиновые захваты, Fmax 150 кН PDF 259 KB

- Информация о продукте: Клиновые захваты „корпус с клиньями“, Fmax 250 кН PDF 444 KB

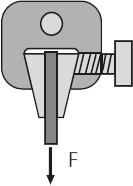

Клино-винтовой захват

Клино-винтовые захваты комбинируют механические свойства винтовых и клиновых захватов. Настройка толщины и создание предварительного усилия зажима осуществляется посредством резьбового соединения. Это предотвращает выскальзывание образца к началу испытания.

Характеристики клино-винтовых захватов:

- Главное усилие зажима обеспечивает клиновой эффект

- Усилие зажима пропорционально актуальному усилию растяжения (самозажим), вследствие чему обеспечивается надежный зажим самых разных материалов

- Благодаря большой зажимной длине, удельное давление удерживается на низком уровне и предотвращается разрушение образца в зажимах

- При использовании больших захватов (Fmax от 50 кН) можно, не демонтируя их, адаптировать малые датчики силы, захваты, инструменты и приспособления с помощью опционального

опорного блока, экономя время - Простая замена губок без использования инструмента

- Клино-винтовые захваты с Fмакс от 50 кН можно опционально эксплуатировать с помощью пневматического мотора. Открытие и закрытие этих захватов осуществляет пневматический мотор, приводной модуль расположен прямо на захвате

- Малая монтажная высота

- пневматического мотора, приводной модуль расположен непосредственно на захвате

- Регулирование скорости деформации по стандартам DIN EN ISO 6892-1:2009 и ASTM E8 – 09

Ключевой момент: отключаемая синхронизация

Благодаря отключаемой синхронизации, клино-винтовые захваты (Fмакс от 10 кН) можно закрывать симметрично и несимметрично. Асимметрию просто настраивать, она надежно сохраняется даже при следующем зажиме. Благодаря этому, даже при испытаниях асимметричных образцов возможно управление одной рукой слева или справа, точка соединения образца всегда расположена на оси испытания.

Загрузки, клино-винтовые захваты

- Информация о продукте: клино-винтовые захваты, Fmax 500 Н / 2,5 кН PDF 530 KB

- Информация о продукте: клино-винтовые захваты, Fmax 10 кН PDF 396 KB

- Информация о продукте: клино-винтовые захваты, Fmax 10 кН / 30 кН PDF 681 KB

- Информация о продукте: ручные клино-винтовые захваты, Fmax 50 кН / 100 кН / 150 кН PDF 580 KB

- Информация о продукте: ручные клино-винтовые захваты, Fmax 250 кН PDF 161 KB

- Информация о продукте: моторизированные клино-винтовые захваты, Fmax 250 кН PDF 535 KB

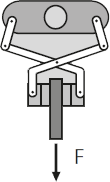

Цанговые захваты

Цанговые захваты являются зажимными приспособлениями с двухсторонним закрытием. Открытие и закрытие осуществляется посредством прижимного рычага. Преднапряженная пружина удерживает захват открытым для загрузки образца. При закрытом захвате преднапряженная пружина создает требуемое усилие прижима. При увеличении усилия растяжения усилие прижима пропорционально повышается, благодаря принципу ножниц. Это обеспечивет автоматический дожим при испытаниях деформируемых образцов.

Цанговые захваты применяются, прежде всего, для испытаний высокоэластичных пластмасс и эластомеров. Принцип ножниц обуславливает сильный рост усилия зажима во время испытания.

Признаки и преимущества цанговых захватов:

- Усилие зажима пропорционально усилию растяжения (самозажим)

- Благодаря боковой подвижности цанговых захватов, нагружение образцов происходит всегда по центру оси растяжения

- Быстрые и простые загрузка и зажим образца, благодаря эргономической и открытой форме

- Благодаря высокой термостойкости и малой монтажной высоте цанговые захваты очень хорошо подходят для использования в термокамерах . Ими легко управлять; благодаря их малой массе быстро достигается температура испытания.

Загрузки, цанговые захваты

- Информация о продукте: клино-винтовые захваты, Fmax 500 Н / 2,5 кН PDF 530 KB

- Информация о продукте: клино-винтовые захваты, Fmax 10 кН PDF 396 KB

- Информация о продукте: клино-винтовые захваты, Fmax 10 кН / 30 кН PDF 681 KB

- Информация о продукте: ручные клино-винтовые захваты, Fmax 50 кН / 100 кН / 150 кН PDF 580 KB

- Информация о продукте: ручные клино-винтовые захваты, Fmax 250 кН PDF 161 KB

- Информация о продукте: моторизированные клино-винтовые захваты, Fmax 250 кН PDF 535 KB

Шарнирные захваты

Шарнирные захваты представляют собой самозажимные приспособления. Зажим осуществляется благодаря действию шарнирного рычага. При подъеме шарнирного рычага устанавливается образец. При этом захват можно оборачивать вокруг шарнирного рычага или зажимать без оборачивания. Шарнирные захваты подходят, прежде всего, для испытаний пластмасс практически при любой температуре.

Характеристики шарнирных захватов:

- Благодаря малой монтажной высоте и температурному диапазону от -15 до +80 °C захваты также подходят для использования в термокамерах

- Исполнение гарантирует быстрый и простой зажим образца

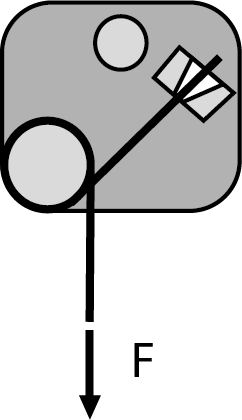

Захваты с обводными элементами

На захватах с обводными элементами используются эксцентрики снятия концентрации напряжения. Усилие в образце уменьшается на протяжении эксцентрика снятия концентрации напряжения. Благодаря этому можно снизить требуемое усилие прижима в концевых зажимах. Максимальная нагрузка испытания варьируется от 500 Н до 20 кН

Преимущества захватов с обводными элементами:

- При пневматических концевых зажимах зажимное усилие остается постоянным, что обеспечивает высокую интенсивность проведения испытаний

- Автоматическая центровка образца, благодаря направляющей канавке в эксцентрике снятия концентрации напряжения

- Благодаря симметричному распределению веса центр тяжести захватов расположен вблизи оси растяжения

- Через захваты на датчик силы не передаются поперечные усилия.

Варианты шарнирных захватов

Существуют различные варианты пневматических захватов с обводными элементами:

- Шарнирные захваты на 360°

- Шарнирные захваты на 90°

- Шарнирные захваты на 180°

- Шарнирные захваты на 270°

Эти пневматические захваты с обводными элементами представляют собой приспособления с односторонним закрытием для зажима образцов в форме нитей. Эксцентрик снятия концентрации напряжения с обводными элементами снижает усилие растяжения перед зажимом. Благодаря пневматическому зажиму, зажимное усилие постоянно, настраивается легко и воспроизводимо. Образец надежно удерживается, предотвращается разрушение в зажимах.

Шарнирные захваты используются для испытаний нитей, шинных кордов, высокопрочных синтетических нитей или стальных шинных кордов.

Преимущества и признаки шарнирных захватов

- Достоверные результаты испытаний, благодаря надежному удержанию даже уменьшающихся образцов

- Высокая интенсивность проведения испытаний, благодаря быстрой установке и центровке образца посредством направляющей канавки

- При смене испытания можно быстро и легко заменить губки без использования инструментов. При этом центровка губок проводится автоматически.

- Простая и быстрая смена образцов двумя руками, благодаря управлению захватами посредством ножного модуля управления (при 180° и 270°)

- Благодаря сменным эксцентрикам снятия концентрации напряжения, захваты можно оптимально адаптировать к различным испытываемым материалам (при 90° и 180°)

- Симметричное распределение веса захвата обеспечивает точное силоизмерение (при 180° и 270°)

- Дополнительно захваты можно также использовать вертикально, без эксцентриков снятия концентрации напряжения (при 90°)

- Два захвата в одном. В зависимости от образца, захваты можно использовать с эксцентриком снятия концентрации напряжения или без него. Это обеспечивает оптимальный зажим даже при смене образцов (при 90°)

Двойные шарнирные захваты

Двойные шарнирные захваты можно использовать для зажима нитеобразных высокоэластичных образцов для испытаний на растяжение. При этом обводном принципе спад усилия возникает в два этапа, который обеспечивает разрыв образца в пределах расчетной длины без разрушения в зажимах. После укладки двойной нити навешивается предварительный груз (не входит в комплект поставки). В этой фазе все три ролика подвижны, чтобы компенсировать продольную деформацию, возникающую вследствие навешивания предварительного груза. При этом регулировка трех значений длины адаптируется к испытываемому материалу. Затем двойная нить зажимается в также регулируемом по высоте захвате.

После закрытия захвата проводится фиксация обводных роликов. Благодаря этому, между роликами и образцом возникает сила трения, щадящим образом уменьшающая усилие растяжения перед концевым зажимом (в захватах). Благодаря этому, образец надежно удерживается, предотвращается разрушение в зажимах. Для зажима двойной нити применяются захваты с постоянным усилием закрытия, т.к. испытываемые материалы часто проскальзывают между зажимными поверхностями.

Двойные шарнирные захваты используют, в основном, для испытаний таких материалов, как резиновые нити и упругие волокна

Преимущества двойных шарнирных захватов:

- Наматывание образца на эксцентрики снятия концентрации напряжения обеспечивает мягкий зажим без разрушения образца в захватах

- Захват гарантирует точное измерение деформации высокоэластичных нитей

- Предотвращение разрушения образцов в захватах позволяет экономить время

Загрузки, шарнирные захваты

- Информация о продукте: Шарнирные захваты, Fmax 10 кН / 20 кН PDF 407 KB

- Информация о продукте: пневматические захваты с обводом 90°, Fmax 1 кН PDF 219 KB

- Информация о продукте: Захваты для высокопрочных синтетических нитей, Fmax 1 кН PDF 364 KB

- Информация о продукте: захваты для высокопрочных синтетических нитей, Fmax 2,5 кН PDF 549 KB

- Информация о продукте: специальные захваты для нитей, Fmax 2,5 кН PDF 483 KB

- Информация о продукте: захваты для испытаний шинных кордов по BISFA, Fmax 10 кН PDF 339 KB

- Информация о продукте: двойные обводные захваты, Fmax 500 Н PDF 372 KB

Захваты для тросов и нитей

Захваты для тросов и нитей можно использовать для испытаний образцов нестабильной формы на растяжение.

Напряжение растяжения образца снижается вследствие фрикционного замыкания на роликах снятия концентрации напряжения. Концевой зажим проводится механически посредством винта (иногда с усилителем), клина или гидравлического зажимного элемента. Образец автоматически центрируется с помощью канавок на роликах снятия концентрации напряжения при наматывании.

Максимальное усилие испытания составляет от 2,5 кН до 100 кН. Захваты можно использовать для испытаний жестких пластмасс и текстильных изделий, металлических материалов, пластмасс и натуральных волокон, высокопрочных тросов и нитей.

Преимущества захватов для тросов и нитей:

- Наматывание образца на эксцентрик снятия концентрации напряжения обеспечивает мягкий зажим без разрушения образца в захватах

- Оптимальная адаптация к различным испытываемым материалам, благодаря сменным эксцентрикам снятия концентрации напряжения

- Для различных материалов доступны различные губки и эксцентрики снятия концентрации напряжения.

- При смене испытания можно быстро и легко заменить губки без использования инструментов. При этом центровка губок проводится автоматически.

Загрузки, захваты для тросов

- Информация о продукте: захваты для канатов, Fmax 2,5 кН PDF 222 KB

- Информация о продукте: захваты для канатов, Fmax 2,5 кН PDF 160 KB

- Информация о продукте: захваты для канатов, Fmax 10 кН / 50 кН PDF 240 KB

- Информация о продукте: захваты для канатов, Fmax 100 кН PDF 144 KB

- Информация о продукте: захваты для канатов, Fmax 100 кН PDF 569 KB

Вальцевые захваты

Вальцевые захваты используют для испытаний образцов в форме полос на растяжение. Усилие зажима создается посредством самозажима захвата вследствие многократного наматывания образца и приложения усилия растяжения. Для точного измерения деформации используют оптические экстензометры.

Преимущества вальцевых захватов

- Доступны захваты с максимальным диапазоном силоизмерения от 2,5 кН до 250 кН

- Благодаря эргономической конструкции можно легко и быстро укладывать образцы спереди в свободно доступную зажимную зону (макс. ширина зажима: 220 мм)

- Захваты подходят для чувствительных к зажиму образцов

- Они также подходят для испытаний втермокамерах (температурный диапазон: -70 ... +250 °C

- Малая монтажная высота захватов позволяет испытывать образцы с большой деформацией

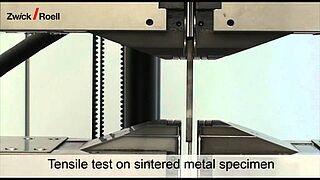

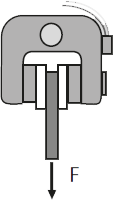

Захваты для образцов с заплечиками, резьбой и болтов

Передача усилия с геометрическим замыканием через заплечики, головки болтов или резьбу. Образец с соответствующими сухарями вставляется в свободно доступный спереди захват и сам собой центрируется на оси растяжения. Доступны захваты с Fmax 50 кН, 250 кН, 600 кН и 1200 кН. Можно проводить испытания стали, цветных металлов и пластмасс по стандартам DIN 50125, DIN EN ISO 6892-1, DIN EN ISO 4762, ISO 4017, DIN 6912, DIN EN ISO 898, ASTM E8 и т.д.

Абсолютно симметричный силовой поток обеспечивают различные конструктивные детали:

- Способ крепления сухарей защищает образец. Обратные удары по сухарям при разрушении образца сведены к минимуму.

- Все сухари охватывают образец полностью. На составные сухари для образцов с заплечиками надевается опорная втулка, которая предотвращает раздвигание сухарей

- Симметричные опорные поверхности в захвате: сухари расположены на двух симметричных опорных поверхностях в захвате.

- Малая монтажная высота экономит место в рабочей зоне

- Чисто механическое решение: Вам не нужен ни пневматический модуль управления, ни гидростанция.

Захваты для образцов в форме колец

Захваты подходят для испытаний колец из эластомеров согласно стандарту DIN 53 504, нормативное кольцо 1 & 2. Захват располагает горизонтально расположенными роликами. Посредством пружинной ленты создается самостоятельное вращательное движение. Это вращательное движение позволяет осуществлять передачу усилия с геометрическим замыканием. При превышении максимально разрешенного хода пружинная лента расцепляется.

Преимущества захватов для колец

- Во время испытания ролики вращаются самостоятельно под воздействием зубчатого ремня или ленты и спиральной приводной пружины

- Простое навешивание образца на свободно доступные ролики (макс. ширина образцов до 80 мм)

- Можно заказать экран для защиты от отскакивающих остатков образцов

- Fmax: 2,5 кН

- Температурный диапазон: -40 ... +150 °C

- Свободно доступные ролики обеспечивают простоту загрузки образца

Захваты для пружин растяжения

Захваты для пружин растяжения доступны в двух исполнениях: тип I с Fmax 50 Н для тонкой пружинной проволоки и тип II с Fmax 10 кН Передача усилия осуществляется через горизонтальные навесные пальцы, диаметр которых может быть разным (максимальный диаметр проволоки пружин 6 мм).

Преимущества захватов для пружин растяжения

- Простая навеска образца на свободно доступные спереди навесные пальцы

- Подходят для испытаний при температурах от - 70 до + 250 C°

Выравнивающие механизмы

Точное выравнивание оси испытания системы является основным условием для получения надежных результатов. С особенной тщательностью и точностью следует проводить выравнивание при испытаниях хрупких материалов (например, стекло, волокнистые композиты и различные металлы). По этой причине фирма ZwickRoell предлагает выравнивающий механизм для корректировки осевого смещения и угловой погрешности.

Испытательные приспособления

Испытательные приспособления фирмы ZwickRoell отличаются широким спектром возможностей применения. В плане диапазона усилия, ширины раскрытия и температурного диапазона предлагается большое количество стандартных решений.

- Испытания на сжатие

- Испытание на изгиб: приспособление для испытаний на 3-точечный изгиб и приспособление для испытаний на 4-точечный изгиб

- Испытания пластмасс

- Испытания пищевых продуктов и упаковки

- Испытания в области медицинской техники и фармацевтической промышленности

- Испытания композитов

- Испытания бумаги, картона и санитарно-гигиенической бумаги

- Испытания текстильных изделий

- Испытание стройматериалов

- Испытания пружин

Захват или испытательное приспособление?

Мы располагаем не только захватами, но и разнообразными приспособлениями для специальных испытаний.

Получите больше информации о наших испытательных приспособлениях или свяжитесь с нами напрямую!

Испытательные приспособления Связаться сейчас