Seat Testing in the Automotive Industry

Seat testing plays a central role in the development and quality assurance of vehicle interiors. Whether comfort, safety or durability – with ZwickRoell testing systems, OEMs, suppliers, and development centers test car seats and their components in a standard-compliant and reproducible manner. From foam testing to dynamic loading of complete seat systems, we have the right solution.

Standardized foam testing Testing systems for seat testing Headrests Center armrests Contact us Downloads

Foam testing - standardized test methods according to ISO, ASTM, and OEM factory standards

Numerous international standards and OEM factory standards are used when testing foams, for example for seat cushions, but also headrests and side bolsters. Our testing machines support all common procedures:

| Test | ISO | ASTM | OEM standard |

|---|---|---|---|

| Indentation hardness (specimens) | ISO 2439 | ASTM D3574-B1 | General Motors GMI 60283-7, Toyota TSM 7100G-4.2 |

| Indentation hardness (molded parts) | DIN 53579 | ASTM D3574-B2 | VW PV3410 Section 4.3 & 4.4, Daimler DBL 5452, BMW QV 52009-1, General Motors GMW 14359, Ford WSS-M15P20-B1/B2, FIAT 7.M8300-D1, Nissan M 0086, PSA 41 1427, Toyota TSF 6223G |

| compression force deflection test | ISO 3386-1/-2 | ASTM D3574-C | VW PV3410, Daimler DBL 5452, BMW QV 52009-1, General Motors GMW 15471 & GME-GMI 60283-8, PSA D 41003 & D 4115413, Renault N° 1002 & N° 1541, Toyota TSM 7100 G-4.2 |

| Tensile Strength | ISO 1798 | ASTM D3574-E | VW PV 3410, Daimler DBL 5452, BMW QV 52009-1, Ford WSK - M99 P32 A, General Motors GMW 15471, PSA D411050, Toyota TSM 7100G |

| Tear strength | ISO 8067 | ASTM D3574-F | VW PV 3410, Daimler DBL 5452, BMW QV 52009-1, Ford WSS-M15P20-B1/B2, General Motors GMW 15471, PSA D 411048 & D 411049 |

| fatigue by constant-load pounding | ISO 3385 | ASTM D3574-I3 | BMW QV 52009-2, Daimler DBL 5452, General Motors GMW 15471 & GME 60283-8, PSA D 421047, Renault n° 1047, Toyota TS M7100G-4.8 |

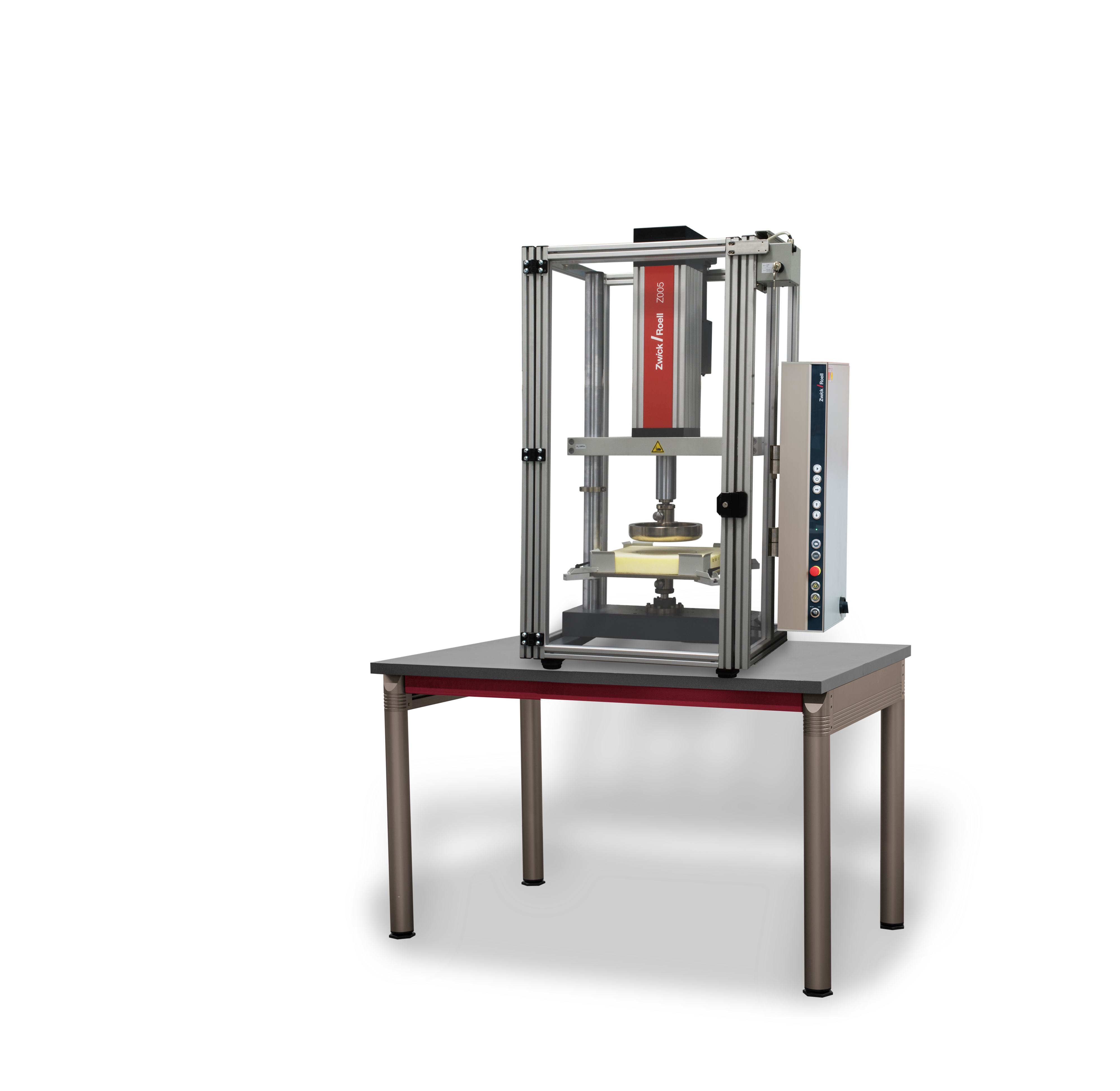

Standard testing machines for standardized foam testing

Our systems for foam and seat testing offer high precision and repeatability – from standard tests to dynamic tests with automated specimen handling. ZwickRoell has various testing solutions depending on the requirements of the test as well as the OEM.

Special testing system for automotive seat testing

ZwickRoell has developed a testing system to determine the overall quality of car seats. The testing system enables not only the seat and seat frame to be tested, but also the hardness and fatigue of the processed foams in accordance with the above-mentioned common standards. The testing system is also used to test sensor mats incorporated into the seat and used to control the vehicle’s automatic settings, for example, correct airbag deployment.

The seats and frames (including the rear seat) are tested in various positions. To maximize versatility of the electromechanical servo testing actuator it is installed in a portal specially developed by ZwickRoell. It provides electrically powered travel in the X and Y directions, together with crosshead height adjustment. Positioning at a defined angle can be retrofitted optionally. Indenters for foam tests as per standard along with a safety housing complete the package.

If you have a large testing volume and want to carry out foam testing in accordance with standard specifications in a repeatable, reproducible and therefore, reliable manner,

ZwickRoell can automate almost any test on soft foam—we have years of experience in this field. Our roboTest R testing system would be your top choice for these tests.

Allow us to advise you today in terms of implementation options, costs and return on investment.

Request a consultation today Learn more about the roboTest R Why automate?

Testing of headrests

In case of emergency, headrests should absorb the energy that is generated by a backwards head movement. They should store as little energy as possible so that your head is continuously slowed down but not accelerated back into the opposite direction. This characteristic should remain throughout the entire life of the headrest. An electromechanical servo testing actuator can easily determine the stiffness and durability of vehicle headrests.

Testing of center armrests

The center armrest example shows the importance of component testing on interior elements.

- First and foremost, it must be ensured that the backrest can reliably withstand localized maximum forces—such as those caused by an elbow—as well as the driver’s weight in various seating positions, without shifting or failing.

- Adjustment force and deformation measurements are also important for assessing comfort.