Closed loop control

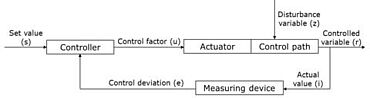

In general, a closed-loop control system is used to bring a specified physical quantity (control variable, r) to a desired value (set value, s) and maintaining it at this level by measuring and adjusting the actual value (i). The closed loop continuously performs the measurement, comparison and adjustment tasks.

In order to execute a control task, the actual value must be measured by a measuring device, then compared with the set value and adjusted by means of an actuator in the event of any deviations. The actual value of the control variable is measured by a measuring device. Then the difference between actual and set values is determined. This is described as the control deviation (e = s – i) and represents the actual input variable for the controller. Based on its transfer function, the controller calculates a control parameter (u) that drives the actuator, which is part of the control path. Consequently, the control path is the part of the overall system affected by the controller. It begins at the actuation point (at the position where the actuator intervenes in the action chain) and ends at the measuring point (at the position where the control variable is measured). A control process is triggered either by a change in the set value or by the effects of a disturbance. A disturbance could be, for example, a sudden change in the ambient temperature. The variable that causes the disturbance is referred to as the disturbance variable (z). Every change in the disturbance variable leads to a change in the actual value, which in turn triggers a control process to return the system to the desired state.

Advantages of closed loop control in hardness testing

The principle of electronically controlled and permanently monitored load application by means of a closed-loop control systemprovides decisive benefits for hardness testers.

- The force is applied precisely and monitored continuously, which ensures both the prevention of an overshoot when the indenter is mounted as well as a high level of insensitivity to vibration.

- The test cycle is controlled electronically, thereby guaranteeing a high degree of repeatability independent of the operator.

- Furthermore, adherence to the strictly regulated times for pre-load and main load stipulated in the ISO and ASTM standards series is guaranteed, which is not the case with manual test initiation.