Outstanding Service and testXpert: Why Superior Essex Relies on ZwickRoell

For more than ten years, US-based Superior Essex has relied on ZwickRoell for quality testing. In addition to the machine quality, the testing accuracy and the fast and individual service support, the specialist for wire and cable products was convinced by our testXpert testing software. This is why the Superior Essex Product Development Center (PDC) now houses six ZwickRoell testing machines, including a modernized Instron® machine.

Highest quality and guaranteed standard compliant

“As a specialist for cable and wires, our main test challenges are to get reliable, traceable and repeatable results. For us, the top priority is to obtain accurate data, since we perform a large part of the tests for cable development and the results are integrated in our product development process,” says Martina Upton, Laboratory Manager at Superior Essex.

The company, headquartered in Kennesaw, GA in the United States, is a global company and specialist in the development, manufacturing and supply of wire and cable products. The products are used in a wide range of industries, including automotive and telecommunications, and support networking and data exchange in, for example, electric vehicles, power transformers, commercial generators or data communication cables in residential and commercial environments. To ensure that the products meet strict industry standards, quality is of utmost importance and is one of the reasons why Superior Essex relies on ZwickRoell’s experience in materials testing.

Service and software lead decision to increased reliability

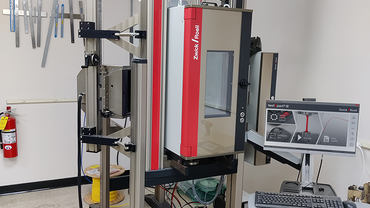

“Reasons why we chose ZwickRoell for all our machines was the service and software,” explains Upton. To date, Superior Essex is using six machines in their lab: three universal testing machines, two electromechanical testing actuators, and a modernized Instron® materials testing machine. For compression tests, the company may use the modernized Instron® machine—the retrofit machine from ZwickRoell—with a new control unit and up-to-date testing software, perfect for a wide range of standards and guidelines.

And this retrofit testing machine is precisely the reason why Superior Essex now relies entirely on ZwickRoell machines. “At the time, we couldn't get in touch with an Instron® technician for calibration purposes. The ZwickRoell team, on the other hand, was helpful and friendly and ready to calibrate our machine on site, which prompted us to convert the machine entirely to a ZwickRoell testing machine. In addition to now having simplified software control, our users are able to quickly do their work with this machine in the lab. Service is also much easier and quicker.”

Our testXpert testing software gave the company another reason to modernize their old Instron® machine. All of our testing systems are now synchronized through the testXpert software platform. “Testing is easier because all of our systems are on a single software platform, which is much more user-friendly than our previous system. The testXpert software solution does the work for us, and the preset test configuration ensures that our results are precise and traceable, every single time. Exactly as we imagined it,” says Upton, positively summarizing the company’s experience with ZwickRoell testing machines.

Extensometers further ensure accurate test results

The Product Development Center (PDC) at Superior Essex is responsible for new cable designs, cable qualification testing and materials testing of cable components. To cover this comprehensive product portfolio, the company performs a wide range of tests. A notable difference in quality of the material to be tested is found in the age of the specimens themselves. To highlight the difference between aged and unaged specimens, comparative aging tests are implemented between seven and 30 days, and for up to 40 hours of continuous loading. Uncomplicated and standardized laboratory processes are therefore of great significance to Superior Essex.

The Superior Essex lab team also relies on technologically advanced accessories to support testing, including a ZwickRoell longstroke extensometer and a non-contact laserXtens extensometer. One of the universal testing machines is used to measure the coefficient of thermal expansion of cable components and whole cable sections. To do this, the material is held with a constant force, while the temperature in the temperature chamber changes from -70 °C to +100 °C and the non-contact laserXtens measures the strain and contraction of the sample.

"Some of our specimens are very sensitive. Extensometers from other manufacturers that we have used in the past cut through our specimens. The ZwickRoell contact extensometers have knife edges that tilt, so the specimens stay intact, and we achieve optimal test results," indicated Martina Upton. Another universal testing machine is used primarily for materials testing—it is equipped with a contact extensometer that measures the tensile and elongation properties of aged and unaged plastics (dog bone specimens) as well as aramid yarns, fiberglass rods and aluminum strips.

Test data helps in the development and manufacturing of new cable products

Cable qualification testing is performed on a purpose-built tensile test rig with a ZwickRoell electromechanical servo test cylinder as the drive. According to industry standards (e.g.,Telecordia GR20, ICEA S-87-640, etc.), at least 100 meters of cable must be subjected to a load and tested for light attenuation at the optical fiber. This is done by connecting one end of the cable to a laser, and the other end to a detector that measures the light loss. When a force is applied horizontally to the cable, the optical device measures the change in the amount of light received. Superior Essex uses the same test rig to measure fiber elongation as well as fiber overlength. "Imagine a fiber optic cable hanging between two poles. If the length of the fiber is the same as the length of the cable, those forces will also act on the fiber when the cable sags or blows in the wind. To mitigate this, excess fiber length (EFL) is added to the cable. If too little is added, the fiber can break within the cable. On the other hand, if too much is added, unnecessary costs are incurred," Upton explains.

Using ZwickRoell electromechanical servo test cylinders, Superior Essex is able to precisely measure cable strain at specific loads. "We use the data obtained using our ZwickRoell equipment along with optical strain data to calculate exactly at what cable length the cable will be loaded." This data is of great value to the company's cable development and manufacturing processes, as these measurements can be used to recalculate the EFL to ensure that the cable has been manufactured in accordance with the design.