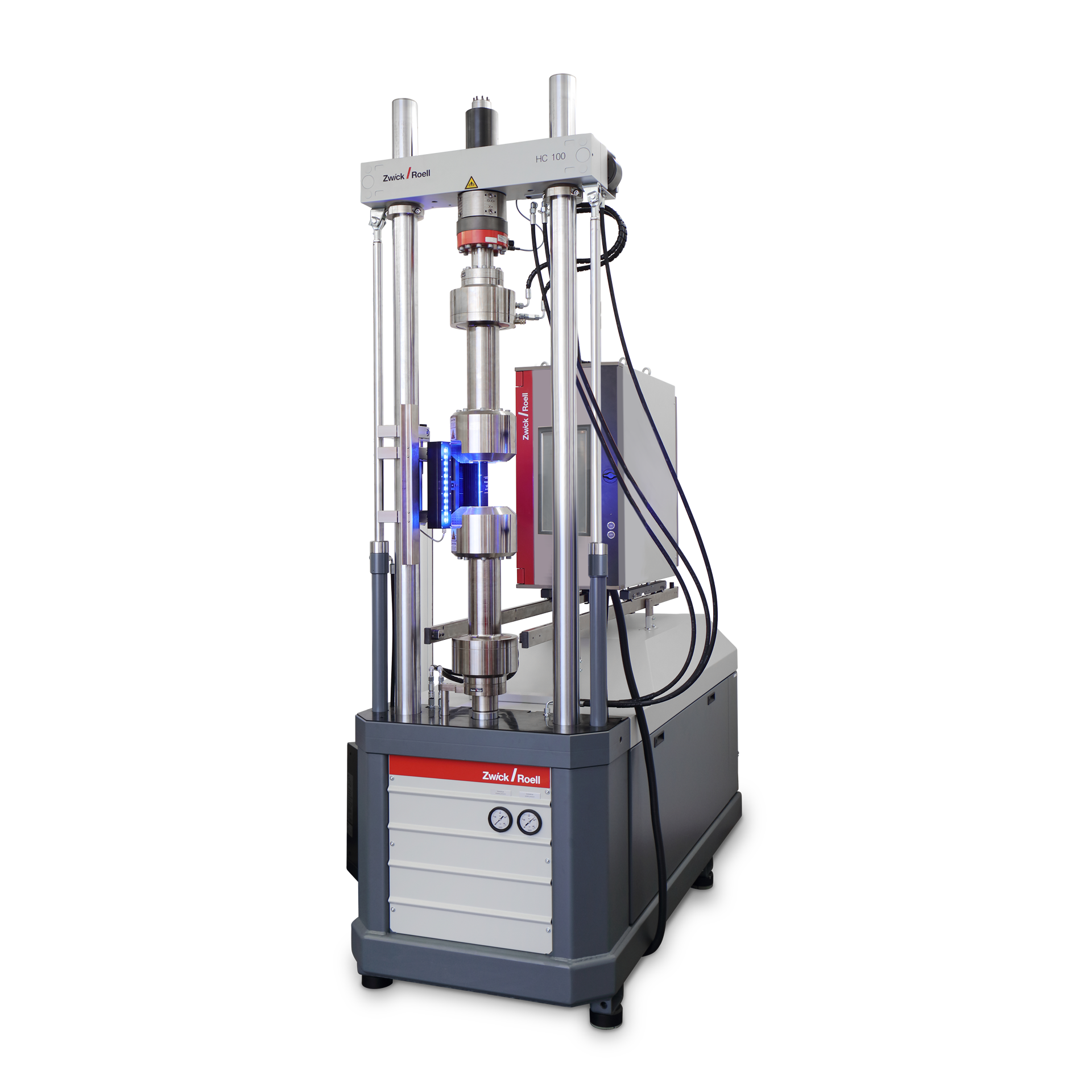

HC Compact servohydraulic testing machine

Compact testing system with integrated hydraulic power pack Download- 10 kN - 100 kN

- Fatigue

- Fracture mechanics

- LCF

- ISO 12106

- ASTM E606

- DIN 50100

- ASTM E399

- ASTM E647

- ASTM E466

Compact testing system with hydraulic power pack

The HC series compact testing system is a complete testing system in which the low noise power pack serves as the substructure for the test frame, keeping the machine’s footprint to a minimum. Combined with special sound insulation for the hydraulic power pack, the HC Compact is ideal for operation in a laboratory.

The HC Compact testing machine is available in two sizes.

- The HC Compact 10/25 kN is designed for fatigue tests on smaller components, down to and including biomedical tests. The machine is equipped with a T-slotted platform and the testing actuator is therefore located in the upper crosshead.

- The HC Compact 50/100 kN is adapted for a full range of accessories for tests on composites, with which both static and dynamic testing can be performed. Due to the high stiffness of the load frame and easy connection of a high-temperature furnace, this machine is also optimally suited for LCF tests.

A temperature chamber can be installed on both models without a lot of effort. The machines can be equipped with an optional alignment fixture for applications with particularly high demands on the alignment of the load string (e.g. LCF tests).

Videos on the servohydraulic compact testing system

Technical overview

| HC Compact 10/25 | HC Compact 50/100 | |

|---|---|---|

|  | |

| Force levels |

|

|

| Power rating | 12 lpm | 30 lpm |

| Testing actuator | Upper crosshead | Lower crosshead |

| T-slotted platform | ✓ | ✓ |

| Temperature chamber | - | ✓ |

| High-temperature furnace | - | ✓ |

| Alignment fixture | ✓ | ✓ |

| Typical Applications |

|

|

| Test area height | Standard | Extended by 250 mm1 | Extended by 500 mm | |

| Dynamic nominal force | 25 | 25 | 25 | kN |

| A - max. height of end of column | 2240 | 2490 | 2740 | mm |

| AG100 – max. height with 100mm testing actuator | 2725 | 2975 | 3225 | mm |

| AG250 – max. height with 250mm testing actuator | 3025 | 3275 | 3525 | mm |

| B - max. width | 720 | 720 | 720 | mm |

| C - max. depth | 1360 | 1360 | 1360 | mm |

| F - height of top edge of lower crosshead | 995 | 995 | 995 | mm |

| K - total weight2 | 1080 | 1095 | 1120 | kg |

| C1 – max. depth of test frame | 450 | 450 | 450 | mm |

| D1 - distance between columns | 460 | 460 | 460 | mm |

| E – column diameter | 65 | 65 | 65 | mm |

| G – max. test area height3 | 1070 | 1320 | 1570 | mm |

| H – max. working test area height4 | 310 to 1010 | 560 to 1260 | 810 to 1510 | mm |

| Frame stiffness at 1000mm crosshead separation | 300 | 300 | 300 | kN/mm |

| T-slots | as per DIN 650 12H12, spacing 80 mm | |||

| Connection size | Ø 70 mm, 6 x M8 and Ø 115 mm, 4 x M8 | |||

| Clamping/ adjustment: manual/manual | 1037238 | 1037462 | 1037469 | |

| Clamping/ adjustment: manual/hydraulic | 1036930 | 1036931 | 1037473 | |

- Required for use with temperature chamber

- With oil and 100mm testing actuator, no grips

- Distance between upper and lower crossheads

- Distance between piston flange and lower crosshead with piston retracted

| Test area height | Standard | Extended by 500 mm1 | |

| Dynamic nominal force | 50/100 | 50/100 | kN |

| A – max. height of end of column | 2320 | 2820 | mm |

| (with alignment fixture) | (2430) | (2930) | mm |

| B – max. width | 860 | 860 | mm |

| C – max. depth | 2000 | 2000 | mm |

| D1 – distance between columns | 445 | 445 | mm |

| E – column diameter | 80 | 80 | mm |

| F – height of top edge of lower crosshead | 872 | 872 | mm |

| G – max. height of test area2 | 350 ... 1175 | 600 ... 1680 | mm |

| K – total weight3 | 1700 | 1750 | kg |

| Frame stiffness at 1000 mm crosshead separation | 500 | 500 | kN/mm |

| Connection dimension | Ø 105 mm, 12 x M10 | ||

| HC 100 – clamping/adjustment: hydraulic/hydraulic | 1085595 | 1085611 | |

| HC 50 – clamping/adjustment: hydraulic/hydraulic | 3010277 | 3010276 | |

- Required for use with temperature chamber

- Distance between piston flange and lower crosshead with piston retracted

- With oil and 100 mm testing actuator, no grips

| Noise level | <58 | dB(A) |

| System pressure | 210 | bar |

| Nominal output | 10.7 | l/min |

| Volume, oil reservoir | 160 | l |

| Coolant water req. max. | 5 | l/min |

| Cooland water inlet temperature | 15 … 28 | °C |

| Emitted heat | 0,8 | kW |

| Electrical supply | 400, 3PH/N/PE, 50 Hz1 | V |

| Motor power rating | 5 | kW |

| Weight with oil | 690 | kg |

| Item No. | 1036929 |

- Or: 440 V, 3PH/N/PE, 60 Hz

| Noise level | <58 | dB(A) |

| System pressure | 280 | bar |

| Nominal output | 30 | l/min |

| Volume, oil reservoir | 160 | l |

| Coolant water req. max. | 30 | l/min |

| Cooland water inlet temperature | 15 … 28 | °C |

| Emitted heat | 0,5 | kW |

| Electrical connection | 400, 3PH/N/PE, 50 Hz1 | V |

| Motor power rating | 15 | kW |

| Item No. | 3009244 |

- Or: 440 V, 3PH/N/PE, 60 Hz

Testing in an extended temperature range

The servohydraulic HC50/100 compact testing system is particularly suitable for use at elevated temperatures thanks to the testing actuator mounted in the lower crosshead. Tests in different temperature ranges are used to determine the effect of specific temperatures on material properties. For these tests, ZwickRoell offers various temperature chambers and high-temperature furnaces that guarantee the perfect solution for every application.

Temperature chambers are mainly used in low cycle fatigue tests (LCF tests) to investigate the effects of thermal stress on the fatigue behavior of materials. Testing temperatures up to 1,000 °C are not uncommon when it comes to LCF tests.

Since composites are often used in components that are subject to thermal stress, testing is also carried out in the elevated temperature range. For static and dynamic composites testing, the load frame also features a particularly stiff design and can be equipped with an optional alignment fixture. All relevant static test fixtures for composites can be integrated in the machine. This makes it the ultimate composites testing machine.

testXpert R – our software for dynamic testing

testXpert R is used with servohydraulic testing machines, vibrophores and electrodynamic testing machines. The testing software offers the right test programs for fatigue tests, fracture mechanics, low cycle fatigue (LCF). A graphical block editor is available for free test configurations, where up to 100 blocks can be parameterized.

Downloads

- Product Information: HC Compact servohydraulic testing machine 10/25 kN PDF 307 KB

- Product Information: HC Compact servohydraulic testing machine 50/100 kN PDF 354 KB

- Product Information: HC series servohydraulic testing machine PDF 293 KB

- Product Brochure: Dynamic and Fatigue Testing Systems PDF 5 MB