Benefits of instrumental texture analysis

- Conversion of sensory tests to objective values: important test criteria such as freshness, crispiness, spreadability are determined objectively.

- Small deviations can be measured and shown in values.

- Standardization of testing methods (company standards) enable different production sites to achieve the same product quality. This is very important in highly automated production lines, and for suppliers of semi-finished goods, ingredients, and food systems. All of this helps to avoid complaints at the outset by improving quality and consistency of the products.

- The tests deliver reproducible results.

- All results can be shown and interpreted in a graph and documentation of all results is easy.

- Proper documentation of product quality simplifies negotiations between suppliers, processors, and customers.

Indenter for determining hardness of food products

These dies are used mostly for penetration tests to determine the hardness of foods. These tests are widely used and can be used for many foods.

Choosing the appropriate die is fundamental: cylindrical dies apply compressive stress to the surface and shear stress to the edges and the outer surface area. Ball dies start with vertical forces and during the test more and more horizontal forces are added.

ZwickRoell offers indenters of various shapes, sizes, and materials to meet all of your requirements.

Special dies: Bread firmness to AACC, gel strength

For the determination of the bread firmness according to AACC74-09 a cylindrical die compresses bread slices up to 40% in two cycles. At a compression of 25% the CFV (compression force value) is determined.

The gel strength according to Bloom (GME Monograph 2005, ISO 9665) is measured by many gelatin producers and processors.

The gel strength in grams Bloom is the mass necessary to depress a standard plunger 4 mm into the gel. The method includes comprehensive specimen preparation in special Bloom jars.

Kramer shear cell

Biting characteristics, crispiness, firmness of food.

The Kramer shear cell simulates a single bite of food and provides information about the bite characteristic, crispiness and firmness. It is used for meat and fish products, small sized fruit and vegetables, as well as for cereals and snacks like potato chips.

The 5- or 10-shear blades drive at a constant speed through the specimen material, compressing, shearing, and extruding it through the slotted base. The test is made on a defined sample quantity. The multiple blades provide measurements for several positions at the same time, compensating for local texture deviations.

Warner Bratzler shear device

In the Warner Bratzler test a blade cuts through a specimen. The shear behavior gives information about the toughness and tenderness of meat and fish products, the crispness of sausages, as well as the bite characteristic of cakes and pastries.

The straight blade is mainly used for rectangular specimens and the notched blade for round specimens like sausages.

Because of the good reproducibility of the results, this test is widely used.

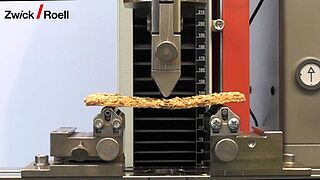

3-point flexure test kit: breaking strength of food

In a 3-point flexure test the specimen lies on two anvils and is centrally loaded with an upper anvil. The span is adaptable to the specimen.

This test is ideal for brittle products, which are produced with identical specimen dimensions, for example waffles, cookies, chocolate bars, and noodle products.

Flexure strength and breaking strength, fracturability and brittleness enable conclusions to be drawn for different recipes. Furthermore you can analyze the influence of moisture, baking time and temperature as well as packing and storage on the product characteristics.

Compression die

Also for determination of the stacking behavior

For the compression test the specimen is smaller than the compression die. Even under compression, the specimen should not extend past the edges of the die.

The compression test is performed on brittle specimens to determine the brittleness, freshness, and firmness of specimens such as candies, coffee beans, or fruit (for the determination of the stacking behavior).

The test is carried out as a cyclic procedure on elastic specimens such as bread, cake, cheese, fish, and marshmallows: The specimen is compressed twice to a certain degree and then decompressed. The compression and recovery behavior shows firmness, stickiness, degree of ripeness, and visco-elastic properties.

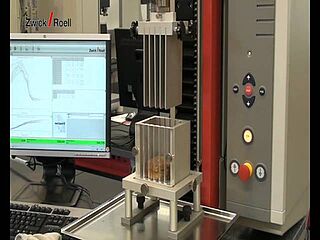

OTMS cell, Ottawa cell

The OTMS cell (Ottawa Texture Measuring System) determines the firmness of products by compression and extrusion. It is used to determine characteristics such as ripeness, tenderness, crispiness or extrusion work on a defined sample quantity. This method is suited for products that are easy to extrude such as canned vegetables, cream cheese, and pâté. It can also be used for extrudates and cereals.

Various extrusion plates and reduction inserts to reduce volume makes it easy to adapt the fixture to different specimen materials. The measurement of pure compression forces is possible with the use of the sealing plate.

Multiple back extrusion cell

Several manufacturing processes gradually break down the fat crystal network of fats like butter and margarine. This material change is measured by the work softening or the remaining hardness.

The back extrusion die with multiple holes extrudes the fat in several cycles. The test determines the remaining hardness after a defined number of cycles or the number of cycles required to reach a defined remaining hardness.

With other test sequences the fixture is also used for ice cream, fresh cheese or cooked pasta.

Dough tensile test fixture

Extensibility, elasticity, stickiness of dough and gluten

The dough tensile test is a micro-scale tensile test: only a small volume of flour or dough is needed. The test determines the processing characteristics, extensibility, elasticity and stickiness of dough and glutens.

This is useful for the comparison of different flours and baking ingredients as well as for the determination of their influence on the baked good. Various recipes, processing types and times, as well as additives, can be improved to achieve the optimal end product.

Alternatively the fixture can be used to determine the elastic characteristics of chewing gum.

Butter cutter: Butter firmness, ISO 16305

This test tool is used to determine butter firmness according to ISO 16305. In this test a stainless steel wire cuts through a defined cube of butter. This test is very dependent on temperature and is performed to a standard method in a temperate water bath.

The butter cutter is also used for the determination of the cutting strength of cheese, eggs, vegetables, and fruit.

Puncture needle

Ripeness of fruits/vegetables, hardness of skin

The penetration test, also called "puncture test" or "force penetration", is used frequently to test the degree of ripeness of fruits and vegetables as well as of the skin strength.

The puncture needle is pushed into the specimen to a certain depth. Depending on the skin and the consistency of the pulp distinctive curves arise.

Hardness tester for sausage and fish products

ZwickRoell has developed a range of hardness testers for fish, meat, and lunch meats. A compression cylinder with a large surface area is used as an indenter to measure the hardness of sausage or the freshness of fish and obtain comparable quality control data.

Temperature and climatic chambers for food

Foods change their characteristics depending on the humidity and ambient temperature. According to the sensitivity of the product it may be necessary to precondition the specimens or test under defined, constant temperature. Examples for this are the testing of ice cream at a storage temperature of -20 °C, or the testing of pizza cheese at approx. +80 °C.

ZwickRoell has developed a temperature chamber especially for these applications for use with the zwickiLine texture analyzer. Separate temperature or climatic chambers are also available according to your requirements.

Customized test fixtures

You have a product with striking characteristics and want to choose the most suitable test method? This requires a unique test tool or fixture. ZwickRoell can develop and produce the most suitable tool for your product and your test method. And if required, you will receive a customer-specific software program specific to your exact test sequence and test results.

Videos

Downloads

- Product Information: Kramer shear cell PDF 402 KB

- Product Information: Warner-Bratzler shear device PDF 281 KB

- Product Information: Compression Die PDF 148 KB

- Product Information: Ottawa cell (OTMS cell) PDF 5 MB

- Product Information: Dough tensile test fixture PDF 374 KB

- Product Information: Butter Cutter PDF 142 KB

- Product Information: Puncture needle for Texture Analysis PDF 277 KB

- Industry Brochure: Food & Packaging PDF 2 MB