ASTM E345 & DIN 50154 – Tensile test on metallic foils

The international standards ASTM E345 and DIN 50154 describe standard test methods for tensile tests on metallic foils and thin strips (usually with a nominal thickness of less than 0.200 mm). Both standards ensure reproducible and comparable results when characterizing strength, ductility and elasticity module.

Applications Determined characteristic values Running a test & Testing equipment Automation options Specimen shapes & Geometries Battery testing laboratory Downloads Request a consultation

Where are ASTM E345 and DIN 50154 primarily used?

DIN 50154 was originally developed for aluminum foils used in the packaging industry. This area remains a key focus to this day, as packaging films require consistent quality, high ductility, and mechanical stability.

However, the standard is now used in combination with ASTM E345 in significantly broader applications – for all technical metallic films, from aluminum and copper to titanium and lithium metal. This makes tensile tests according to these standards relevant not only for traditional applications, but also for key technologies in electromobility and hydrogen:

- Packaging industry: Aluminum foils for food and pharmaceutical packaging

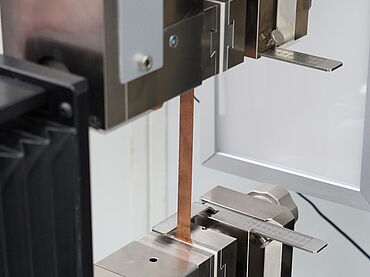

- Battery research and production: Lithium-ion batteries use extremely thin metallic foils – copper foils on the anode side (approximately 4.5–12 µm) and aluminum foils on the cathode side (approximately 8–20 µm). These serve as current collectors and carrier material for the active layers in lithium-ion batteries. The tensile test ensures that the materials can withstand the loads of the production process and the battery’s fatigue life. Coated electrodes can also be tested to meet standards.

More information on battery testing - Hydrogen and green energy technology: Titanium foils in bipolar plates for fuel cells – tensile strength is the key factor determining the fatigue life and safety of these components.

More on fuel cell testing - Automotive testing: Testing fins in car radiators, where thin films and strips must reliably withstand mechanical loads.

At the European level, work is currently underway to further develop standardization (CEN, EN) to better adapt test methods to new materials and applications in the future. By actively participating in the development of standards, particularly for battery materials and fuel cell testing, ZwickRoell ensures that its testing solutions will continue to meet all requirements in the future.

What characteristic values are determined in ASTM E345 and DIN 50154?

The ASTM E345 and DIN 50154 standards are used to determine the key mechanical characteristic values of thin metallic foils:

- 0.2 % Offset yield (Rp0,2) – proof of the elastic-plastic transition limit

- Tensile strength (Rm) – the film's maximum load-bearing capacity

- Strain at break (A50 or A100) – a measure of ductility and enlongation

- Elasticity module (Young's modulus) – the stiffness of the material

These characteristic values provide valuable information for material development, quality assurance and fatigue life evaluation.

Running a test and testing equipment to ASTM E345 and DIN 50154

The thin metallic foils are sensitive and place increased demand on the testing equipment. This starts with machining the specimens through the clamping to the testing of specimens:

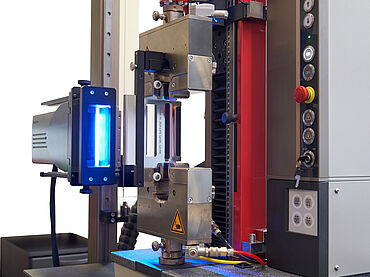

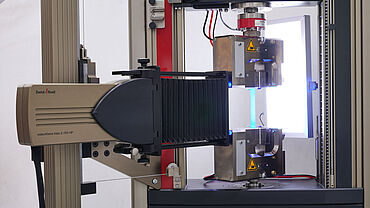

- Testing machine: Due to the low test forces that occur when testing films, the single-column universal testing machine zwickiLine with test loads up to 1kN is ideally suited. Due to the highly accurate calibration of our load cells, existing testing machines with higher load frame capacities can also be used fully compliant with standards to ISO 7500-1 or ASTM E4 (class 1 or better).

- Specimen preparation: Thin metallic foils are extremely sensitive to kinks, notches and dents. For clean and notch-free specimen machining, ZwickRoell recommends, among other things, the use of the foil strip cutter, which ensures optimal and reproducible cutting quality and specimen dimensions with only one cut.

- Handling and inserting the specimen: To minimize operator influence and damage to the specimen and to ensure vertical alignment, the Easy insertion tool can support the user in inserting the specimen precisely and stress-free, especially for specimen under 0.1 mm thickness. An alignment plate ensures correct positioning before the specimen is inserted into the holder via a guide.

- Specimen clamping and force transmission: Secure clamping without damage and slipping of the sensitive films is possible, for example, with pneumatic grips and rubberized grip insert, which ensure a constant closing pressure. Furthermore, we provide a wide range of inserts and specimen grips for the perfect setup of the machine for every application.

The automatic force zeroing control via the testXpert software additionally protects the specimen from unwanted preloading during clamping. Slipping or plastic deformation of the specimen in the jaws would lead to incorrect values of the strain at break being measured. - Strain measurement: If, in addition to the tensile strength Rm and the strain at break A50 or A100, the offset yield Rp0.2 is also to be determined, the strain measurement by means of an extensometer is required. For high-precision results as well as for demanding modulus of elasticity measurement, we recommend the Video extensometer videoXtens biax, which works contactless and does not require any specimen marking. In addition to the time savings due to the elimination of specimen marking, contactless extensometers offer clear benefits over the clip-on extensometer/sensor arm extensometer, since possible damage to the thin specimen by the knife edge and the influence of the drag force of the knife edge on the test results are excluded.

- Running a test: The standards ASTM E345 and DIN 50154 were derived from the standardization for tensile tests on metal to ASTM E8 and ISO 6892-1 and adapted to the testing of thin films, so that reference is made to these standards in large parts with regard to running a test, test parameters, and characteristic values.

- Data acquisition and evaluation: The testXpert testing software guides the user through the entire test sequence in accordance with standards. Standard test programs already contain the relevant standard specifications of ASTM E345 and DIN 50154. In addition, the integration of the videoXtens extensometer allows a 2D-DIC analysis: Virtual gauge lengths can be set, alignment quality checked and inhomogeneities quantified – without additional hardware.

Special requirements for the test equipment for tensile tests on lithium metal foils

Particular challenges arise when testing lithium metal foil, as their tensile strength can only be determined in an inert atmosphere. i.e. in a dry room or under inert gas. The zwickiLine testing machine is placed in a special glove box to ensure precise testing under controlled conditions. The use of the Easy insertion tools for safe insertion of the specimen is also guaranteed with gloves.

Advantages of ZwickRoell test equipment for reliable, reproducible test results

- Reliable specimen handling: Minimized operator influence, optimal vertical alignment of the specimen due to the Easy insertion tool and automatic zero force control

- Gentle force transmission: Pneumatic grips with constant closing pressure prevent specimen damage

- Non-contact strain measurement: No marking step required, specimen remains unaffected

- High reproducibility: Clean specimen preparation and precise clamping technology

- Maximum flexibility: One software for all evaluations, including integrated 2D-DIC analysis

- Secure specimen preparation and testing even in an inert environment: Exact test results even with special requirements in lithium metal foil testing.

- Optional: Automated testing systems for higher specimen throughput and less operator influence

Automation options for metal foil testing

In order to be able to run automated tensile tests on metallic foils, our robotic testing system roboTest N is available, for example. A specially developed specimen gripper was adapted to the special requirements of non-rigid specimens. This allows the metal foils to be transported safely in the automatic system.

Due to the automated process, the specimen are always positioned at the same location in the specimen grips. Off-centered or angled specimen clamping of the specimen can thus be excluded, which is of great importance for reliable test results, especially for thin specimens.

The thickness measurement can be performed on steel foils using a probe. Alternatively, the thickness can also be determined by measuring the weight. Here, the weight of the specimen is calculated in relation to its dimensions and the known material density. This method is ideally suited for aluminum foils.

Increase specimen throughput and minimize operator influence with our automation solutions for metal foil testing.

Comprehensive know-how and experience in materials testing, access to all high-precision testing machines and the complete accessories portfolio in our ZwickRoell Battery Test Center are available for your application technology consultation.

Are you interested in free pretesting in our Battery Test Center? We're happy to assist you in the selection of the right test equipment for your needs.

Our new battery testing laboratory is equipped with the state-of-the-art testing technology that covers different mechanical battery tests for cell characterization both in the field of research and development and in battery production. Two application experts are available to our customers for both onsite and remote testing. In this way, we want to ensure that we find the best possible testing concept for the respective requirements of our customers.

Take a virtual look around our laboratory or contact us today – we will be happy to advise you!

Which specimen shapes and geometries are defined in ASTM E345 and DIN 50154?

The two standards specify different specimen shape in order to test a wide range of materials in accordance with the standards. The choice of specimen shape depends on the material, thickness and the characteristic values to be determined. Smooth, notch-free cut edges are absolutely necessary.

ASTM E345 (types A, B, C specimens)*:

- Type A:Dumbbell specimen with wider grip ends: Grip-to-grip separation in the shoulder area min. 50 mm, reduced initial gauge length 50.0 mm (1.969 in.) or 50.8 mm (2.0 in.) and in the parallel area of the specimen with a length of min. 60 mm (2.25 in.) and initial width 12.7 mm (0.5 in.).

- Type B: parallel strip specimen with a total length of at least 230 mm (9.0 in.), a free grip-to-grip separation between the clamping jaws of at least 125 mm (4.92 in.), a width of 12.7 mm (0.5 in.).

- Type C: parallel strip specimen, which differs only in the initial width of 15.0 mm (0.591 in.) from type B.

DIN 50154 (strip specimen without heads type 1a and 1b depending on the test technique and the characteristic values to be determined)**:

Strip specimen with an initial gauge length (L0) of 50 mm or preferably 100 mm, a length in the gripping range (grip-to-grip separation) of ≥ 25 mm each. The initial width of the specimen is 15 mm.

- Strip specimen 1a) (strain measurement using an extensometer: Total length of the specimen min. 120 mm or 170 mm with a free grip-to-grip separation between the clamping jaws (Lc) ≥L0 + 20 mm

- Strip specimen 1b) (strain measurement via crosshead travel): Here Lc = L0

* See also. ASTM E345-24a Section “6.Test Specimen” p. 2-3

** See also DIN 50154:2019-09 Section “7 Specimen”

ABOUT THE AUTHOR:

Dr. Harald Schmid

Global Industry Manager Metals | ZwickRoell GmbH & Co. KG

As Global Industry Manager, he is responsible for the industry strategy in the metals sector with a focus on market observation, further development of testing solutions and sales support in the international environment.

He has extensive experience in standardization work and is actively involved in various committees, including the international ISO committee ISO/TC 164 Mechanical Testing of Metals and national DIN working groups such as NA 062-01-42 AA Tensile and ductility testing for metals and NA 062-01-47 AA Impact test for metals and mechanical-technological testing of metallic pipes.

His academic career began with a degree in mechanical engineering (B.Sc. & M.Sc.) at the Karlsruhe Institute of Technology (KIT). After holding international positions in mechanical engineering, he worked as a research assistant at the Friedrich-Alexander-University Erlangen-Nuremberg with a focus on material characterization and sheet metal forming. He dedicated his doctorate to the topic of deep drawing processes with drawing beads.

Downloads for metal foil testing

- Product information: zwickiLine Up to Fmax 5 kN PDF 820 KB

- Product information: videoXtens biax 2-150 HP PDF 2 MB

- Product Information: Lightweight Robot roboTest N PDF 140 KB

- Product Information: 2D Digital Image Correlation (DIC) PDF 1 MB

- Product Information: "Easy insertion tool" insertion aid PDF 714 KB

- Industry Brochure: Battery testing PDF 11 MB