VDA 238-100 Small Plate Bending Test for Metallic Materials

VDA 238-100 describes how to perform a small plate bending test on specimens made of metallic materials such as aluminum alloys and ultra high-strength steels (tensile strength Rm ≥ 780 MPa). Since 2017, the requirements for the test fixture have been very strict, ensuring that the measured bending angle reflects only the material itself and is not influenced by the test fixture. This allows for a better assessment of the material's formability.

The following information provides a comprehensive overview. However, to ensure that the small plate bending test is performed in compliance with the VDA 238-100 standard, it is essential to reference the full standard.

Objective & applications Specimen preparation & specimens Stiffness requirements Running a test 3-point flexure test kitOptical functions Automation options Request a consultation

VDA 238-100 Objective & Applications

The small plate bending test according to VDA 238-100 is used to determine the bending angle of, for example, car body panels. The goal is to obtain information about the deformation behavior and susceptibility to failure of metallic materials during forming processes with predominantly bending components (such as hemming operations) or under crash loading.

The guideline was developed in collaboration with manufacturers and suppliers in the automotive industry to establish a uniform global standard for automotive applications.

VDA 238-100 Specimen preparation and specimens

The quality of specimen preparation has a significant impact on the test. Therefore, VDA 238-100 prescribes various steps for careful specimen preparation. The surface of the specimen must be clean, and the edges should be deburred, ground, or otherwise finished if necessary.

The specimens for the small plate bending test are small flat metal plates with a standard size of 60 mm × 60 mm. If high test loads are expected, the specimen width can be reduced in consultation with the client.

Materials with high formability can be pre-stretched for better characterization.

VDA 238-100 Stiffness requirements for the test fixture

The stiffness of the test fixture is decisive for the test results. If the stiffness is low, the deformation of the test fixture influences the determined bending angle, i.e. it is lower than it should actually be. “For bending angles αset > 130°, the stiffness of the test fixture must be verified. With a punch force of 3000 N, the total expansion of the rollers must not exceed 0.1 mm” (Source:VDA 238-100:2020-07, Section 4 Test apparatus and test equipment, Publisher: VDA [ German Association of the Automotive Industry]).

We meet the required high stiffness with our testing fixture for small plate bending tests with maximum precision.

VDA 238-100 Test preparation

The flexure test kit is positioned in the tensile testing machine so that the rollers are parallel and centered below the die with a tolerance of ±0.05 mm. The roller distance is defined in VDA 238-100 as a function of the calculated target bending angle αset:

| Steel | 2 tm + 0.5 mm | |

| Al alloys | αset ≤ 130° | 2 tm |

| αset > 130° | 2 tm + 0.5 mm for t ≤ 2.0 mm |

tm = Specimen thickness before the test, t = nominal thickness

The specimens must be positioned symmetrically on the rollers so that the force can be applied with the die in the middle of the support distance. Depending on the material and thickness of the specimen, the radius of the die is selected as follows:

| Steel (Rm ≥ 780 MPa) | 0.4 mm | |

| Al alloys | 0.2 mm for t ≤ 2.0 mm | 0.4 mm for t > 2.0 mm |

Running at test according to VDA 238-100

The specimen is bent at defined test speeds until one of the three shutdown criteria is reached:

- Reduction in force:

Steel = 60 N

Aluminum t ≤ 2.0 mm = 30 N

Aluminum t > 2.0 mm = 60 N - Switch-off at a crosshead travel that ensures a bending angle after the expected reduction in force of 30 N or 60 N and before clamping

- Switch-off in the event of a significant increase in force

Determination of the bending angle

VDA 238-100 describes three ways of determining the bending angle for the evaluation:

- Manually (αₘ) according to Annex C: The bending angle α is measured manually using a protractor after removing the specimen from the flexure test kit. In this case, only the plastic deformation is measured.

- Calculation (α꜀) according to Annex D: The bending angle α꜀ is calculated with software support on the basis of the crosshead movement, whereby the bending angle includes the plastic and elastic deformation.

- Optical (αₒ) according to Annex E: The bending angle αₒ is determined using a high-precision camera system while the specimen is being loaded. A camera measures the bending angle directly on the specimen during the test. This test measures plastic and elastic deformation.

"Through our close collaboration with leading industry players, we know that a high bending angle is a key criterion for high material quality. In turn, high stiffness of the test fixture is crucial. And that was precisely the focus of development. However, simple, fast, and safe operation was also important to us – because this ensures the fixture meets the demands of daily use. Together with customers, we have intensively tested and further developed the test fixture. The result is a product that, in addition to technical precision, offers one thing above all: genuine, practical expertise."

Dr. Erhard Reimann, Product Manager for static testing systems for metals

Small plate bending test to VDA 238-100 with ZwickRoell

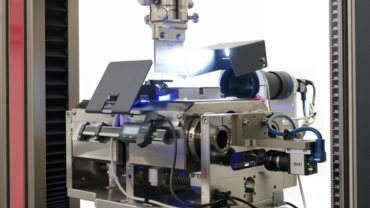

The small plate flexure test kit from ZwickRoell was developed in cooperation with a major automobile manufacturer. It not only fulfills the requirements of VDA 238-100, but is also perfectly adapted to everyday testing: Easy handling, minimal operator influence, and smart support through optical measurement and analysis options.

Do you also use the testing machine for other applications? It is not necessary to remove the test fixture. Various specimen holders or test tools can be mounted directly on the small plate flexure test kit using an adapter.

Automated small plate bending test

For especially reliable and accurate test results, the small plate bending test can also be automated.

With the robotic testing system roboTest N from ZwickRoell, a robot handles the specimen and precisely inserts the specimen in the flexure test kit. Operator influences such as hand temperature or hand moisture, as well as angled or inaccurate insertion of metal specimens can be completely eliminated by the robot.

A reader initially scans the ID code on the sheet metal specimen, ensuring the specimen data is accurately assigned with the test results.

Because the small plate bending test can be performed on sheets of varying thicknesses, the next step is to determine the specimen thickness at a thickness measurement station. The robot selects the appropriate die for the specimen thickness and inserts it into the test fixture. Additionally, the roller distance of the flexure test kit is automatically adapted to the die.

Automating the small plate bending test according to VDA 238-100 frees qualified laboratory personnel from routine tasks, allowing them to focus on more complex work.

Video to automated small plate bending test

The automated small plate bending test is used in this video because many specimens of different thicknesses need to be tested.

The automated testing system roboTest N ensures that specimens are consistently positioned in the test fixture for every test. The human factor is minimized.