Multiaxial puncture test on plastics to ISO 6603-2, ISO 7765-2, ASTM D3763

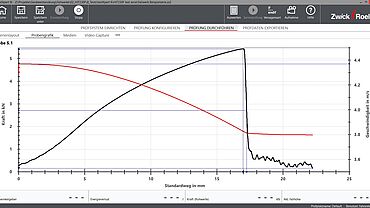

Puncture tests are of particular interest for molding materials. This type of test imposes a multi-axis stress condition on a thin plate, which is induced at a high strain rate. The result is: a force time or force travel diagram and single-point data that describe both the deflection of characteristic points of the diagram and the maximum force.

Puncture tests on plates are defined in standards ISO 6603-2 and ASTM D3763. ISO 7765-2 is a variation of the standard and is used for testing films.

The tests are performed using a drop height of 1 m, which corresponds to an impact velocity of 4.43 m/s. The potential energy of the drop weight must be at least 2.73 times greater than the puncture energy absorbed by the specimen. This ensures compliance with the standard after limiting the loss of speed by a maximum of 20% of the impact velocity.

In the case of viscous polymers, such as polycarbonate, in particular, friction occurs at the tip of the indenter, which would lead to a significant falsification of the test results. For this reason, the standards state that the indenter must be lightly lubricated.

To test at low temperatures, the test plates must be conditioned to the test temperature for a sufficient amount of time. Depending on the test temperature, commercial coolers can be used. They should be located close to the test instrument. For the test, the specimens are removed from the cooler and placed in the drop weight tester. They are then tested within a few seconds.

The Amsler HIT230F and Amsler HIT600F series drop weight testers are designed to allow easy access to the specimen table. Activating the two-hand release closes the clamp, covering all movable masses. This means there is no risk to the operator and the test can be performed in seconds. In contrast to instruments with integrated temperature chambers, this series features high specimen throughput for puncture tests and very easy operation. Amsler HIT1100F and Amsler HIT2000F series drop weight testers are more strongly suited for part, component and function testing, but can also be equipped for instrumented puncture tests, Charpy, Izod and high-speed tensile tests.

Take advantage of the leading testing software in materials testing

ZwickRoell’s testXpert testing software offers:

- Simple operation: start testing right away and be a testXpert while maintaining maximum safety.

- Reliable and efficient testing: benefit from reliable test results and maximum testing efficiency.

- Flexible integration: testXpert is the optimal solution for all of your applications and processes—simply put, a more effective workflow.

- Future-proof design: testing software for the entire life cycle, ready for your future test tasks!