Modernization of Testing Machines

Allow us to future-proof your existing testing machine! A ZwickRoell modernization will return your testing machine to state-of-the-art condition. Take advantage of the wide range of benefits that await and extend the service life of your machine for many more years in a sustainable manner.

Our modernizations also cover testing machines from more than 50 third-party manufacturers. With several thousands of modernization projects under our belt, you can rely on the collective experience and the level of quality ZwickRoell is known for.

| Benefits of modernizing | ZwickRoell modernization | Third-party machine modernization |

|

|

Reasons for modernizing Customer testimonials Downloads FAQs

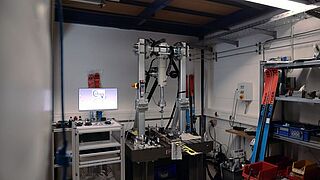

Modernization of a testing machine at our headquarters in Ulm

In this video we show you the step-by-step process of modernizing an AllroundLine floor-standing testing machine at the ZwickRoell headquarters in Ulm. The result: a universal testing machine with the latest measurement and control electronics, the latest generation of software and a new drive, making it comparable to a brand new machine.

What does the modernization of a testing machine include?

During a modernization, the existing load frame is refurbished and the electronics, the drive and the testing software are fully upgraded. A modernized testing machine is completely equivalent to a new machine and therefore offers you the same benefits and possibilities. In addition, it saves you money when compared to purchasing a new testing machine and contributes to protecting the environment.

Reasons for modernizing your testing machine

- Outdated testing technology and/or outdated software

- Changing test tasks or applications, or integration of new products or accessories

- Termination of support for existing operating system or measurement and control electronics

- Long downtime and waiting periods for replacement of obsolete electronic components

- Increase in operating safety requirements

- Use of new digital tools, such as testXpert Analytics or remote support

Modernization of dynamic testing machines

Whether servohydraulic, electromechanical testing machines, or vibrophores, our modernization packages consistently offer the right solution for any of these dynamic testing machines. The retrofit kits consist of the following basic elements:

- Powerful testControl II measurement and control electronics

- testXpert testing software

- Special retrofit kits for adaptation of existing sensors such as load cells, extensometers, etc.

- High-quality proportional or servo valves, hydraulic hoses or hydraulic accumulators

- New hydraulic power pack or adaptation of existing hydraulic components

A few of the customers we’ve impressed with our dynamic machine modernizations

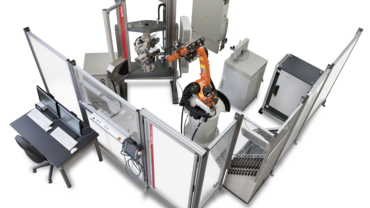

Modernization of automated testing systems

In addition to static and dynamic testing machines, automated testing systems can also be modernized. Here, a modernization includes:

- Update of our autoEdition automation software or testXpert, as well as establishing connections to customer-specific databases.

- Integration of a new system computer incl. a Windows upgrade

- Replacement of the robot

- testControl II measurement and control electronics

- Replacement of mechanical control components including valve terminals or bus couplers and mechanically stressed components such as specimen grippers

Modernization of third-party machines

We can easily modernize third-party machines with our latest ZwickRoell testing technology, using the same components and high quality standards we apply to our own machines. To date, we have modernized machines from more than 50 different manufacturers. These include:

- Instron®

- Hegewald & Peschke

- Shimadzu

- MTS

- Tinius Olsen

- Schenck

- Rumul

- Walter+bai

- And many more

Spare parts availability for 10 more years

Along with a modernization of your testing machine, comes our promise of renewed spare parts availability for at least 10 more years. This greatly exceeds common industry requirements and ensures that you can rely on your machine for the long run. You not only benefit from a new testing machine, but also our excellent spare parts service, customized spare parts packages and 24-hour spare parts shipping.

Downloads

- Product Information: Reliable Service and Future Upgradeability with Current Technology PDF 541 KB

- Product Information: Modernization Packages for Static and Dynamic Testing Machines - For Over 50 Manufacturers PDF 1 MB

- Product Information: Modernization of Hegewald & Peschke Equipment PDF 304 KB

- Product Information: Modernization of Static Testing Machines PDF 1 MB

Frequently asked questions about testing machine modernizations

A retrofit universal testing machine is a universal testing machine that has been returned to state-of-the-art condition through modernization. Whether static, dynamic, automated or other testing machines, ZwickRoell modernizes any testing machine and instrument, including those from third-party manufacturers.

Modernization of a testing machine includes not only the replacement of the electronics, but also the AC drive, the latest generation of testXpert testing software, the latest sensor technology and accessories.

ZwickRoell has modernized machines from more than 50 third-party manufacturers. During the modernization, we return your testing machine and the electronics to state-of-the-art condition. If you own an aging testing machine from Instron, MTS, Shimadzu, Hegewald & Peschke, Galdabini, Schenck or any other manufacturer, we will modernize it completely so you can continue running reliable and standard-compliant tests for many more years to come.

After ZwickRoell has modernized your third-party machine, we become your contact for any machine-related aspect, whether spare parts, software adaptations, expansion of your accessories portfolio or calibration requests. With the modernization, you have a testing machine that is in no way inferior to a ZwickRoell testing machine in mint condition, and are taking advantage of our comprehensive and outstanding customer support services.