ASTM D412 Tensile Test on Rubber and Elastomers

The ASTM D412 standard defines procedures used to evaluate the tensile (tension) properties of vulcanized thermoset rubber and thermoplastic elastomers.

- Thermoset rubber is cured and set into a shape through heat application. Curing is an irreversible chemical reaction, which makes thermoset rubber products stronger and more durable. Products made of thermoset rubbers include tires, hockey pucks, circuit breakers, electrical housing, and motor components.

- Thermoplastic elastomers (TPE) are polymers, polymer blends or compounds. They normally begin in pellet form, become liquid when heated, and can then be injected into a mold, for example. The thermoplastic takes shape as it cools and hardens. This process can be reversed by re-heating the material. TPE applications include drive belts, shock absorbers, breathing tubes, catheters, and shoe soles.

Another standardized method for determining the tensile properties of vulcanized thermosetting rubber and thermoplastic elastomers is described in the standards ISO 37 and DIN 53504.

The following content explains the key aspects. For standard-compliant testing in accordance with ASTM D412, however, it is essential to purchase the complete standard.

Objectives and & applications Specimens Test performance and characteristic values Test equipment requirements Testing systems Automation

ASTM D412 objective & applications

ASTM D412 provides specifications for the testing machine, the test specimens (including shape and size), and for the test procedure and appropriate methods to be used. The objective of the test is to determine various material characteristic values, which can then be used in the development of new products, in meeting product performance goals, or for research and quality control.

The materials described in ASTM D412 are used on a daily basis in a variety of industries, including aerospace, construction, medical engineering, e.g. in the testing of rubber gloves, the automotive industry, among others, in the testing of tires, dampers, seals, and much more.

Specimens and dimensions in accordance with ASTM D412

- For the tensile test on rubber and elastomers, ASTM D412 specifies six types of dumbbell specimens and two types of cut ring specimens.

- The most commonly used specimen is a C-shape dumbbell specimen (ASTM D412 Type C) with an overall length of 115 mm (4.5 inches), gauge length of 25 mm (1 inch), measurement width of 6 mm (0.25 inches) and thickness of 3 mm. Three measurements must be made of the thickness, whereby the median of the three measurements is used as the thickness in calculating the cross sectional area.

| Standard | Type | Note | l3 mm | l1 mm | b2 mm | b1 mm | h mm | L0 mm | Shape |

|---|---|---|---|---|---|---|---|---|---|

| ASTM D412 | C | Preferred specimen | ≥115 | 33 | 25±1 | 6+0.05 | 1.3 ... 3.3 | 25±0.25 | Dumbbell specimen |

| ASTM D412 | A | Possible dimensions | ≥140 | 59±2 | 25±1 | 12+0.05 | 1.3 ... 3.3 | 50±0.5 | Dumbbell specimen |

| ASTM D412 | B | Possible dimensions | ≥40 | 59±2 | 25±1 | 6+0.05 | 1.3 ... 3.3 | 50±0.5 | Dumbbell specimen |

| ASTM D412 | D | Possible dimensions | ≥100 | 33±2 | 16±1 | 3+0.05 | 1.3 ... 3.3 | 25±0.25 | Dumbbell specimen |

| ASTM D412 | E | Possible dimensions | ≥125 | 59±2 | 16±1 | 3+0.05 | 1.3 ... 3.3 | 50±0.5 | Dumbbell specimen |

| ASTM D412 | F | Possible dimensions | ≥125 | 59±2 | 16±1 | 6+0.05 | 1.3 ... 3.3 | 50±0.5 | Dumbbell specimen |

| ASTM D412 | 1 | Preferred dimensions | 17.9 | 15.9 | 1 ... 3.3 | 50 | Ring specimen | ||

| ASTM D412 | 2 | Larger dimension | 35.8 | 31.8 | 1 ... 3.3 | 100 | Ring specimen |

Performing the test according to ASTM D412

The ASTM D412 standard covers two test methods: Method A and B.

- Method A is based on dumbbell and straight section specimens, while Method B is based on cut ring specimens.

- Tests according to ASTM D412 are used to measure the elasticity of a material under tensile load, as well as the materials behavior after the test, when the load has been removed.

- The test is performed using a universal testing machine (also referred to as tensile testing machine) at a speed of 500 ± 50 mm/min, until the specimen fails.

Characteristic values determined according to ASTM D412

While ASTM D412 is used to measure many different tensile properties, the most important characteristic values include definitions according to ASTM D1566 - Terminology relating to rubber:

- Tensile stress: stress applied to stretch a specimen

- Tensile stress at a given elongation: stress required to stretch the uniform cross section of a test specimen to a given elongation

- Tensile strength: maximum tensile stress applied while stretching a specimen to the point of rupture

- Yield point: the point in the stress-strain curve, short of ultimate failure, where the rate of stress with respect to strain goes through a zero value and may become negative

- Ultimate elongation: the elongation at the time of rupture

- Tensile set: extension remaining after a specimen has been stretched then allowed to retract in a specified manner, expressed as a percentage of the original length

For detailed information and standard procedures, please refer to the ASTM D412 standard.

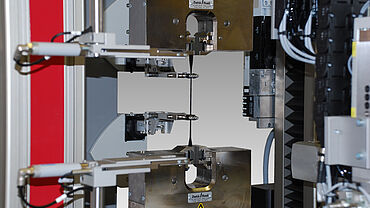

ASTM D412 Testing Systems

A requirement of the test to ASTM D412, is the elongation of the specimen. With the increasing length of the specimen, the travel distance of the crosshead must be long enough—and therefore, the load frame tall enough—to accommodate the extension of the specimen up to the point of break. ZwickRoell offers the right universal testing machines for this:

- zwickiLine – space-saving solution for small test loads up to 5 kN and with a test range up to 1365 mm

- ProLine - for standard-compliant tests and simple applications with a test area from 1050 mm to 1450 mm

- AllroundLine - adaptable and versatile with a test area from 1030 mm to 2560 mm

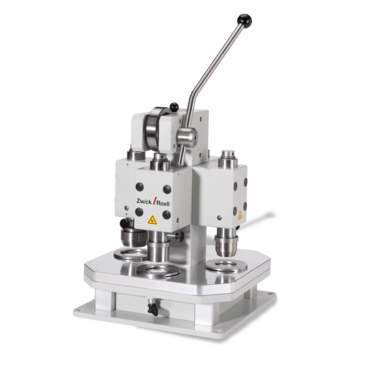

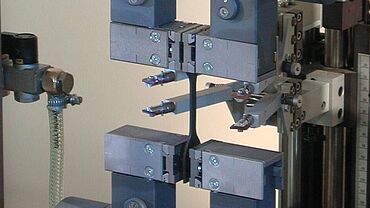

Specimen grips

The specimen grips for dumbbells must automatically tighten, exert uniform pressure on the gripping area, and increase the pressure with increasing load. This prevents slipping and achieves a break in the intended test area. ZwickRoell offers various types of specimen grips, from manual mechanical specimen grips to comfortable pneumatically controlled systems, each with suitable jaw inserts.

- Pneumatic grips:The gripping force is generated by pneumatic actuators and can be operated with a hand or foot control. Gripping force independent of the tensile force ensures a constant test speed over the course of the entire test sequence.

- Pincer grips: double actuator grip. The gripping force is increased proportionally by the pincer principle as the tensile force increases. This ensures automatic retightening for specimens prone to shrinkage.

- For ring specimens, a tool consisting of two rotatable rollers is required.

If you have any questions regarding your testing requirements or challenges around ASTM D412, please feel free to contact our experts.

We look forward to discussing your needs.

Contact us

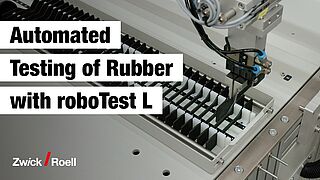

Automated tensile tests in accordance with ASTM D412

Tensile tests on rubber and elastomers to ASTM D412 can also be automated . An automated testing system is primarily used when many specimens need to be tested, or when operator influences must be eliminated. Hand temperature or moisture, as well as inaccurate or angled positioning of the specimen in the specimen grips, can affect the test results.

- The compact roboTest L robotic testing system can autonomously test up to 350 specimens. A thickness measuring device integrated in the system measures the specimen thickness with accuracy and reproducibility. The specimen gripper places the specimen in the testing machine and the tensile test according to ASTM D412 is started automatically. After the test, separate disposal grippers remove the specimen remains from the specimen grips.

- The robotic testing system roboTest R is more complex and allows you to connect additional devices such as a specimen marking station, a centering station or a temperature chamber for accurate tempering of the specimen. The magazine capacity of the robotic testing system can also be expanded as needed.

- To avoid operator influences even with small specimen series (type C), ZwickRoell has the testing system ALEX in its portfolio: simple, compact, and cost-effective, it can be used with a series as small as 10 specimens.

Downloads

- Product Brochure: Testing machines and testing systems for plastics and rubber PDF 9 MB

- Product Information: lightXtens: non-contact, simple, and fully automated testing of high-extension materials PDF 886 KB

- Product Information: videoXtens 1-270 P PDF 1 MB

- Product Information: multiXtens II HP extensometer PDF 1 MB

- Product Information: Robotic testing system roboTest L (linear) for plastics PDF 71 KB

- Product Information: Robotic testing system roboTest R (polar) for plastics PDF 86 KB

- Product Information: ALEX - The automated lab expert PDF 310 KB

Frequently asked questions regarding ASTM D412

The ASTM D412 standard defines procedures used to evaluate the tensile (tension) properties of vulcanized thermoset rubber and thermoplastic elastomers. These tests are critical for determining the mechanical properties of rubber and elastomer materials, which in turn is important for product development, quality assurance and performance testing in a variety of industries, including aerospace, medical, automotive, construction, and more.