Dynamic Materials Testing: Which Drive is Right for My Requirements?

Whether screw, artificial hip joint or vehicle part – components and materials must withstand dynamic loads over their service life. The decisive question: How long does the material withstand the stresses before it fails? This is exactly where dynamic fatigue testing comes in. But not every materials testing machine is the same – especially in the drive, there are big differences that affect not only the test results, but also operating costs and maintenance.

Servohydraulics Video crack toughness Resonance systems Video fatigue testing Linear motor Electromechanical Torsion Comparison tables Testing software Video testXpert RContact us

Servohydraulic: The classic option for the highest demands

Servohydraulic testing machines are considered the standard when it comes to maximum forces, high flexibility and versatile test tasks. They work with hydraulic actuators, which are controlled by precise servo valves. Especially in low cycle fatigue tests (LCF), fracture mechanics tests or highly dynamic applications such as high-speed tensile test and puncture tests (e.g. compliant to ISO 6603-2 or ASTM D3763), hydraulics often have no alternative.

But this power has its price: The permanent compressed air supply of the hydraulic power pack is energy-intensive. The maintenance is comparatively high due to oil and filter changes as well as regular replacement of the hoses. The noise level must not be underestimated. Servohydraulic machines deliver constant results for many years with the proper care, even at forces above 2,000 kN.

Resonance systems: energy efficiency meets high frequency

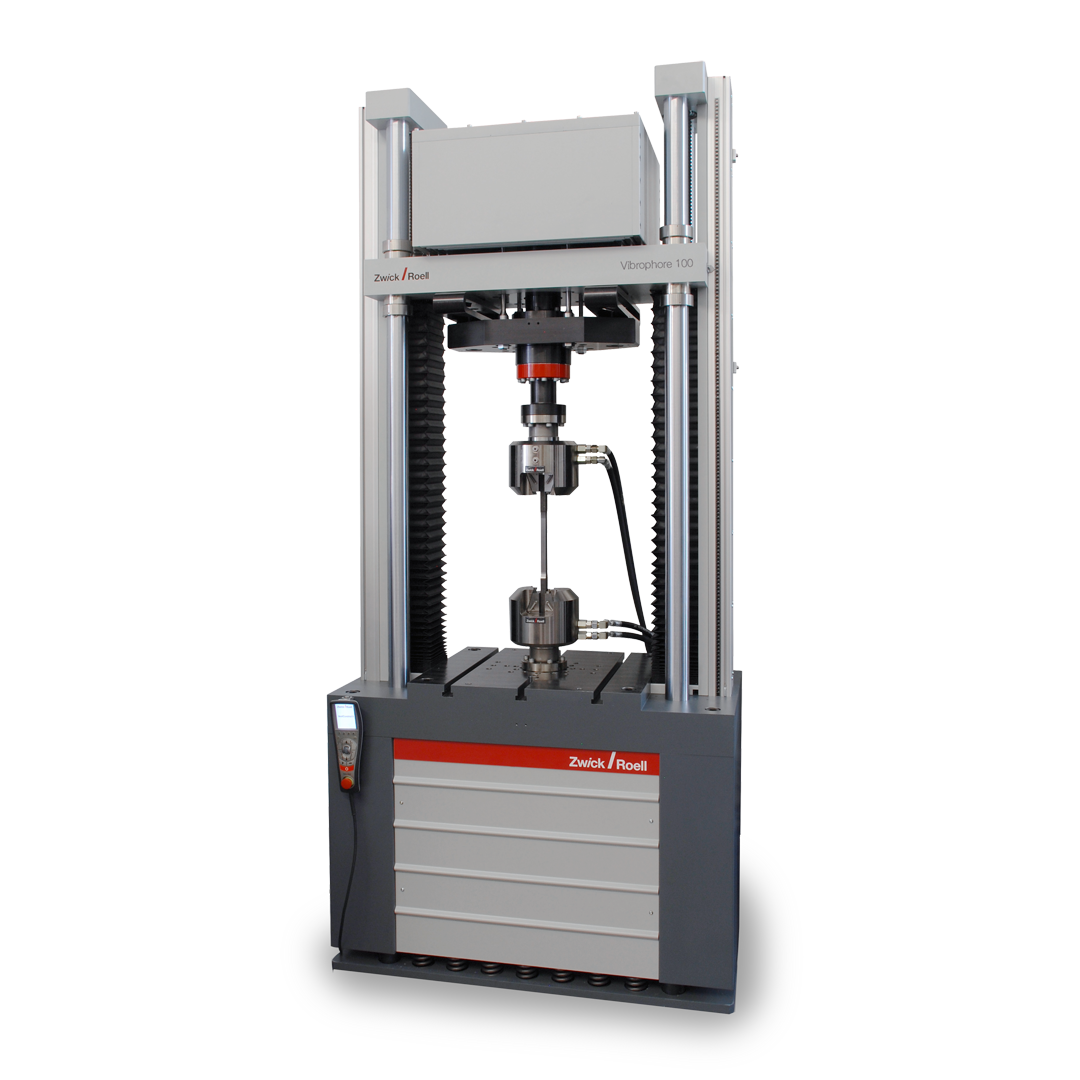

When it comes to fatigue resistance and high-cycle fatigue (HCF), resonance testing machines such as the vibrophore provide an exciting alternative. Unlike servohydraulics, the natural frequency of the test specimen is stimulated by a mechanical system. This creates the desired vibration with minimal energy input. In fact, the power consumption of resonance systems is only about two percent compared to hydraulic machines. Maintenance requirements are also low: no hydraulics, no cooling, no moving valves – yet capable of handling forces up to 1,000 kN.

Normatively, resonance machines are particularly suitable for S-N tests to DIN 50100 and fracture mechanics compliant to ASTM E399 or ISO 12106. In combination with mechanical clamping, they can even cover static materials testing. If you want to regularly test large quantities under constant load, the vibrophore is significantly more cost-effective in the long term.

Electrodynamic with linear motor: Quiet, precise, oil free

In sensitive environments – such as in medical engineering or the electronics industry – noise and oil-free are key criteria. This is where electrodynamic materials testing machines with linear motors (e.g. the LTM series from ZwickRoell) show their strengths. They are quiet (LTM 1/2/3 approx. 46dB(A) at 1 m distance), do not require any media supply and are low-maintenance. At the same time, they enable precise control even with smaller forces up to 10 kN and frequencies above 100 Hz.

They are particularly relevant for testing implants compliant to ISO 14801, ASTM F1717 or ISO 7206, i.e. for products that have to be tested both dynamically and statically. The advantages of the fast and precise response behavior of linear motor technology are also evident in new materials such as biocomposites or plastic compounds.

Electromechanical testing actuators: The middle ground

Between high-performance hydraulics and sensitive electric motors, ZwickRoell also offers electromechanical testing actuators – a mixture of flexibility and energy efficiency. These systems are particularly interesting when medium-sized forces (1 to 100 kN) are required, for example for testing seat foam or composite materials. Electromechanical systems can be integrated modularly, do not require a media supply and only incur minimal maintenance costs.

Don't forget torsion

Not every load is linear. Torsion systems are used especially forimplants or components with rotating stress. ZwickRoell also offers both hydraulic and electrodynamic solutions here. The LTM torsion systems are ideal for smaller torques (e.g. 10-100 Nm), while the servohydraulic versions offer up to 2,500 Nm – depending on the application and standard requirement.

Direct comparison

To make the decision easier, here is a summarized overview of the most important features:

Resonance (vibrophore) |

| |||

|---|---|---|---|---|

| Force range/frequency | 10 – 2,500 kN to 100 Hz | to 1,000 kN to 285 Hz | 1 – 10 kN to 100 (120)Hz | 1 – 100 kN approx. 1 Hz |

| Torsion | To 2,500 Nm | ./. | To 100 Nm | ./. |

| Stroke | To 400 mm | To 6 mm | To 60 mm | To 400 mm |

| Typical standards | ISO 12106, ASTM E606 | DIN 50100, ASTM E466 | ISO 14801, ASTM F1717 | Versatile used effectively |

| Applications | LCF, fracture, quick tests | HCF, fatigue resistance | Component, foils, implants | Composite, foam |

| Operating costs | High (oil, maintenance, power) | Very low | Low | Low |

The corresponding testing software – testXpert R

Typical applications for the testXpert R testing software are fatigue tests and the determination of dynamic material characteristic values. For many applications, such as fracture mechanics, LCF, screw tests or biomechanics it includes standard test programs, but it also offers simple fatigue test programs and a graphical block editor for customized test definition.

Conclusion

The selection of the appropriate drive is far more than a technical decision – it influences operating costs, test accuracy, energy efficiency and ultimately competitiveness. If you want to test economically in the long term, there's no getting around a deep dive into drive technology. ZwickRoell offers the right solution for any requirement – from high-performance hydraulics to quiet linear motors.