Composite Testing

Fiber-reinforced plastics (FRP) are a class of high-performance materials, which due to their excellent weight-specific mechanical properties, very good fatigue behavior and high level of flexibility from a design point, are primarily used for lightweight structures in the aerospace, wind energy and automotive sectors, in addition to various other industries. Generally, multilayer composite laminates made up of individual layers are used for thin-walled structures. The type of fiber-reinforcement ranges from continuous fiber reinforced unidirectional (UD), scrim and woven composites to FRP with discontinuous and randomly distributed reinforcing fibers.

A large number of composite tests exist for the mechanical characterization of FRP materials for the purpose of material development, material qualification, or quality assurance, or for the determination of characteristic values for the layout and design of composite structures:

- The mechanical properties in the main load directions of the single layer as well as the corresponding characteristic values of multilayer composite laminates are determined with static tensile tests on composites, composites compression tests and shear tests.

- For quality assurance purposes, simple static tests such as flexure tests on composites or tests for determination of interlaminar shear strength (ILSS) are commonly used.

- To understand the delamination behavior of typical layered FRP laminates, static tests are performed to determine the interlaminar energy release rate.

- The compression after impact (CAI) test is of relevance for composite structures used in aerospace. This test is used to determine the static compressive residual strength of a laminate pre-damaged by impact loading.

- Other static tests, required primarily for structural design, include test methods for determining the bearing strength and the strength of bonded or bolted connections.

- The fatigue behavior of FRP materials and composites is determined using tests with cyclic dynamic loading.

Composite testing methods:

Tensile tests Compression tests Shear tests Flexure tests ILSS tests Interlaminar energy release rate Compression after impact (CAI) Bearing strength Fatigue test

Additional information on composite material testing:

Modular testing system Testing system for loads up to 600 kN Cryogenic composites testing Alignment services Customer projects

Video: Overview of Test Methods for Composites

Webinar recording on an introduction to composites testing:

Discover ZwickRoell's fundamental mechanical testing methods and advanced solutions for quality assurance and the design of composite structures:

- 01:31 Applications for composite materials

- 06:36 Trends in the composites industry

- 11:51 Basic static in-plane material properties

- 16:25 Composites tensile testing

- 20:58 Alignment

- 23:15 Composites compression testing: end loading, shear loading and combined loading compression

- 28:44 Composites shear testing

- 32:49 3- and 4-point flexure tests

- 34:51 Interlaminar shear strength (ILSS)

- 36:38 Composites testing machines

- 42:12 Strain and deflection measurement

Composite tensile testing

Composite tensile testing is used to determine the tensile modulus and Poisson’s ratio elastic characteristic values, as well as the tensile strength in the main material directions of fiber-reinforced plastics.

- The most common test methods for composite tensile tests are ISO 527-4 & ISO 527-5, ASTM D3039, as well as EN 2561 and EN 2597.

- The airbus factory standard AITM1-0007 includes the test conditions for both tensile tests on unnotched multidirectional laminates and notch tensile tests for determination of the tensile strength using open hole tension (OHT) and filled hole tension (FHT) test methods. Open hole and filled hole tension tests are performed primarily for aerospace applications to determine reduction factors for multidirectional laminates under open or closed hole tensile loading. Other standardized test methods for determination of the open hole and filled hole tensile strength are ASTM D5766 and ASTM D6742.

Composite compression testing and notched compression tests

Composite compression tests are used to determine the compression modulus and the compressive strength in the main material directions of fiber-reinforced plastics. Since the compressive strength in the direction of the laminate fibers is often less than the tensile strength, and the failure modes of an FRP laminate under tensile and compression loading are very different, the compression test plays an important role in testing composites.

A wide variety of test methods and test standards are available for composite compression tests, whereby a distinction is made among three load application principles:

- End loading compression test to ASTM D695, DIN EN 2850 type B and Boeing BSS 7260 type III and IV

- Compression test with shear loading to ASTM D3410, ISO 14126 Method 1, DIN EN 2850 type A and Airbus AITM1-0008 specimen type A

- Compression test with combined loading to ASTM D6641, ISO 14126 Method 2, and Airbus AITM1-0008 specimen type A

In addition to the above-mentioned test methods for determination of the compression values of unnotched laminates, there are standardized notched compression tests on composites for determination of the open hole compressive strength (OHC) to ASTM D6484 and filled hole compression strength (FHC) to ASTM D6742.

Along with the compressive properties of the unnotched laminate, corresponding reduction factors can then be determined for multidirectional laminates under compressive loading. Notched compression tests are further described in industry standards Airbus AITM1-0008 specimen types B, D and C, as well as in Boeing BSS 7260 type I.

Composite shear testing

Composite shear tests are used to determine in-plane shear characteristics of fiber-reinforced plastics, such as the shear modulus and shear strength. For FRP materials with different characteristic values in the main material directions, the shear modulus must always be determined using separate shear tests and cannot be calculated from other elastic characteristic values, as is the case for isotropic materials, for example.

Three different test methods have been established for the determination of shear characteristics and shear behavior:

- Tensile test with ±45° laminate to ISO 14129, ASTM D3518 and Airbus AITM1-0002

- V-notched beam (Iosipescu) shear test to ASTM D5379

- V-notched rail shear test to ASTM D7078

For the tensile test with a ±45° laminate (in-plane shear test), the same test arrangement used for tensile tests can be used. However, recording of the transverse strain, in addition to the axial strain, is mandatory for the calculation of shear strain.

Notched specimens and corresponding test fixtures are required for the Iosipescu and the v-notched rail shear test. Biaxial strain measurement is also required here. Biaxial strain gauges are often used. Alternatively, the strain can be measured using digital image correlation (DIC).

The v-notched shear test can also be used to determine out-of-plane shear values, if laminates are available with the appropriate thickness.

Composite flexure testing

Due to the comparatively simple test arrangement, specimen geometry and machining process, as well as test performance, composite flexure tests are frequently used in quality assurance for fast material comparisons. A distinction is made between 3- and 4-point flexure tests. Common standardized test methods for flexure tests on fiber-reinforced plastics are:

- 3- and 4-point flexure test to ISO 14125 and ASTM D7264

- 3-point flexure test to EN 2562, EN 2746 and ASTM D790

- 4-point flexure test to ASTM D6272

If the stiffness of the entire test arrangement is sufficient, or if the pliability in the test arrangement can be determined and corrected in the testing software, use of the machine travel distance is often permissible in the 3-point flexure test.

The 4-point flexure test, on the other hand, requires measurement of the deflection in the center of the specimen using a suitable displacement measuring systems.

Interlaminar shear strength (ILSS)

The test for determining interlaminar shear strength (ILSS) is one of the most commonly performed static tests for fiber-reinforced plastics and is frequently used in quality assurance. Only a fairly small specimen is required, the test itself is quick and easy to perform, and only the maximum force determined in the test is relevant for evaluation purposes.

Established test standards for the ILSS test are ISO 14130, EN 2377, EN 2563 and ASTM D2344.

All four standards describe a rectangular shape specimen, however they may use different dimensions for specimen length, width and thickness. ASTM D2344 additionally describes a curved specimen, such as one taken from a pressure vessel or pipe wall.

The test fixture used for the ILSS test must be able to meet the very low test arrangement tolerances specified by the test standards.

Tests for the determination of interlaminar energy release rates

The critical energy release rate and energy release rate during steady crack growth are determined using fracture mechanics testing methods to understand the delamination behavior of composite laminates. To manufacture the specimen, a laminate is required in which an artificial tear is created in the center plane of the laminate by means of a very thin and non-adhesive plastic film (Teflon film is often used).

Test methods with crack growth by tensile loading perpendicular to the crack surface (Mode I) and test methods with crack growth by shear loading in the laminate cross-section (Mode II) are most commonly performed. For the calibration of numerical methods for the calculation of crack propagation in a laminate, there is an additional test method of mixed mode I+II loading:

- Mode I as double cantilever beam (DCB) test to ISO 15024, EN 6033, ASTM D5528, Airbus AITM1-0005 and Boeing BSS 7273

- Mode II as end-notched flexure (ENF) test to ASTM D7905, EN 6034, Airbus AITM1-0006 and Boeing BSS 7273

- Mode II as calibrated end-loaded split (C-ELS) test to ISO 15114

- Mixed mode I+II as mixed-mode bending (MMB) test to ASTM D6671

Compression after impact (CAI) test

The compression after impact (CAI) test is a test method used to determine the compressive residual strength of a laminate after impact damage. The specimen to be tested is pre-damaged with impact energies specified in the respective test standard. This method enables conclusions to be drawn about the damage tolerance of a composite laminate in order to ensure the safety and reliability of components, especially in potentially impact-loaded composite structures in the aerospace industry.

The following test methods have been established for the CAI test: ASTM D7136 and ASTM D7137, ISO 18352, Airbus AITM1-0010 and Boeing BSS 7260 type II.

Bearing strength and strength of joints

In addition to the mechanical characteristic values of the fiber-reinforced plastic laminates themselves, tests are also performed to determine the strength of joints for layout and design purposes of composite structures.

The standardized test methods used for this purpose can be roughly divided into three areas:

- Bonding strength of adhesives (lap shear test) to ASTM D5868, EN 6060 and Airbus AITM1-0019

- Strength of bolted or studded connections and bearing response testswith loading in the laminate plane according to ASTM D5961, ASTM D7248, EN 6037, ISO 12815, Airbus AITM1-0009, AITM1-0065 and AITM1-0067

- Fastener pull-through resistance with loading perpendicular to the laminate plane according to ASTM D7332 and Airbus AITM1-0066

Composite fatigue testing

To determine the fatigue behavior of composite laminates and derive S-N curves, dynamic cyclic tests are commonly performed under pulsating tensile load. Applicable standardized dynamic composite tests include ASTM D3479 and ISO 13003. ISO 13003 additionally describes the composite fatigue test under dynamic cyclic flexural load.

Other standardized dynamic composite testing methods are:

- Open hole tension and open hole compression fatigue to ASTM D7615

- Interlaminar crack growth under mode I fatigue load to ASTM D6115

- Fatigue of bolted connections and dynamic bearing response tests to ASTM D6873 and Airbus AITM1-0074

- Airbus AITM1-0075 contains summary information on how to perform ILSS, ILTS, OHT & OHC, FHT & FHC, pull-through, CAI and lap-shear fatigue tests.

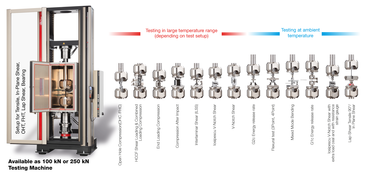

Modular testing machine for composite testing

Larger testing laboratories with correspondingly high test volume use different testing machines for the very diverse composite testing methods, and can thereby minimize conversion efforts. The individual testing machines can be adjusted to the force range required for the various types of tests. If throughput rates are not high or consistent enough that an investment in multiple testing machines makes sense, an alternative option is to equip a single testing machine so that you can perform as many test methods as possible with the least amount of machine conversion effort.

ZwickRoell developed a modular testing machine design for composite testing, which is available as a 100 kN or 250 kN testing machine covering 21 test methods and approximately 120 test standards (ISO, EN, ASTM, as well as Airbus AITM and Boeing BSS), and which allows for comprehensive characterization of fiber-reinforced composites at ambient temperature or for tests at low or high temperatures ranging from -80 °C to +360 °C.