ISO/TS 6892-5 Tensile test of metals on miniaturized specimen

The mini tensile test, also known as the miniaturized tensile test or tensile test with miniaturized specimen is becoming increasingly important in materials testing. This method offers significant advantages, especially when characterizing high-strength and ultra high-strength materials with limited material availability, removal from components or in research and development.

With the publication of ISO/TS 6892-5:2025 (TS=Technical Specification) an international standard was created for the first time that defines specific requirements and procedures for the metals tensile test on miniaturized specimen, thus recognizing the growing importance of this test variant in various industries. ASTM E8/E8M-24, updated in May 2024, also considers this trend and is dedicated specifically to testing miniature specimen in Annex A1.

Applications Challenges Results-reproducibility for standard specimens Specimen types and dimensions

Learn more about our testing portfolio for tensile test on miniaturized tensile specimen:

Testing machines Specimen grips Extensometer & DIC High-temperature Automation Request a consultation Customer projects

What is a mini tensile test and where is it used?

A mini tensile test is a tensile test, which is performed on specimen with significantly reduced dimensions. Typically these are flat or round specimen with smaller cross-sections and shorter gauge lengths. This method makes it possible to determine mechanical properties such as tensile strength, yield point and strain at break with minimal use of material.

While standard flat tensile specimen to ASTM E8 and ISO 6892-1 provide gauge lengths (L0) from 50.0 mm to 200.0 mm, the permissible gauge length of miniature flat tensile specimen to ISO 6892-5 are less than 20 mm and for round specimen less than 15 mm.

More about miniature specimen geometries to ISO and ASTM

In principle, mini tensile tests can be performed on all metallic materials, but are particularly used in the following areas:

- Research & development: When developing new materials, often only small quantities of material are available.

- Additive manufacturing: The specimen production for conventional tensile tests can be time-consuming and costly.

- High-strength materials: The testing of small specimen reduces the required test load and enables precise measurements.

- Mega castings and other components in the automotive Industry: Complex geometries in chassis or body die-cast parts only allow very small specimen geometries to be removed.

Special requirements of the mini tensile test to ISO 6892-5 or ASTM E8 Annex1

Despite their reduced size, the miniaturized tests must be designed in such a way that they can reliably and reproducibly determine the mechanical characteristic values such as tensile strength, yield point and strain at break. Please note the following points:

- The specimen geometry must comply with standards to ensure good reproducibility.

- Due to the small dimensions, the accurate alignment of the specimen in the test arrangement is essential.

- Test speed and strain measurement must be performed with high precision. Suitable sensor arm extensometer or optical measuring system must be used.

- The results are not directly reproducible with standard specimens, unless a reliable correlation has been determined beforehand.

How reproducible are the results between miniaturized specimens and standard specimens?

ISO/TS 6892-5:2025 expressly indicates on page 6, section 4 “Principle” that the test results from miniaturized specimen are not directly reproducible with results to ISO 6892-1.

This means that: Even if the test methods are similar, differences in specimen geometry and scale (size effects) lead to systematic deviations – especially for strain at break (A, At). The influence of grain size and heat development during plastic deformation also plays a role.

The tensile strength (Rm) and yield point (Re), on the other hand, have in many cases a very good level of reproducibility with suitable geometry and implementation.

For reliable statements, we perform reproducible tests in the ZwickRoell application technology testing laboratory and also support you in the selection and configuration of your testing system for testing your miniature tensile specimens.

Karin Hanak - Head of Applications Engineering & Testlabs at ZwickRoell

We will be happy to discuss your needs.

Contact us Learn more about ZwickRoell application technology

ZwickRoell testing solutions for mini tensile tests to ISO/TS 6892-5

The standard ISO/TS 6892-5:2025 and the testing of miniaturized specimen in general place the highest demands on test arrangement, specimen grips, force measurement, specimen alignment and strain measurement. This is exactly where ZwickRoell's strength come in. For testing miniature specimen, there is no single test solution that fits your individual test requirements. Our experts in application technology consulting ensure that we configure the right testing system for you from our different test solutions, guaranteeing reproducible and reliable test results.

For an individualized consultation please contact us! Contact form

The following testing solutions serve as examples:

Materials testing machine Specimen grips and alignment Extensometer High-temperature testing Automated testing solutions

Universal testing machines in a large force range

While classical tests on metal specimens require large test loads, the maximum test load for miniaturized specimen is often in the low force range. Our zwickiLine universal testing machine up to 5 kN is usually sufficient. ZwickRoell universal testing machines – like the proven AllroundLine with test loads up to 250 kN – are calibrated with such precision in the lower force range that even small forces below 5 kN can be accurately measured. This allows miniature specimen to be tested in existing testing system, fully compliant with standards to ISO 7500-1 or ASTM E4 (Class 1 or better).

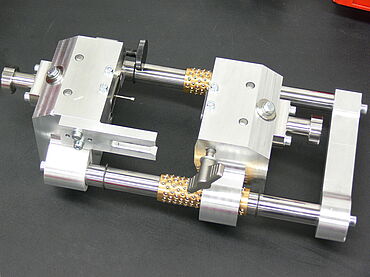

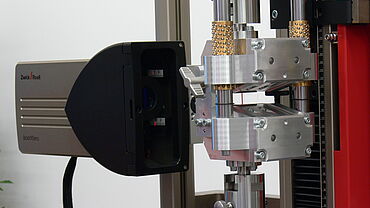

Flexible specimen solutions – customized and adaptable

According to ISO/TS 6892-5 the smallest specimen shape has a gauge length of just 5 mm. ZwickRoell offers a wide range of standard specimen grips providing the ideal solution for your individual miniature specimen: mechanically, pneumatically or hydraulically clamped – adjusted to the material, specimen size, shoulder length and remaining grip-to-grip separation. Our experts will advise you in detail and develop a suitable specimen grip solution with you.

Perfect alignment – a decisive success factor

The precise axial alignment of the specimen is essential for the validity of the test. In addition to an alignment test fixture and precisely adjustable centering stops, our specialists can check the alignment of the specimen if required, which is a central component of our application technology consulting.

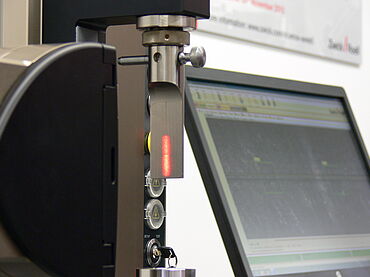

Extensometer for maximum accuracy on a small scale

Precise strain measurement is decisive, especially for short gauge lengths and low strains. ZwickRoell relies on non-contact optical systems like the videoXtens 1-32 HP/TZ – specifically designed for high-temperature range testing such as to ISO 6892-2 and is also well suited for testing miniature specimens at ambient temperature. The high resolution, compensation for lateral specimen movements and automatic tracking of the measurement range ensures reliable results for strain at break, yield point and elasticity module. In addition Digital Image Correlation (DIC) enables a detailed analysis of fracture behavior across the entire specimen length, which is a significant advantage for research and development.

As an alternative to strain measurement with video extensometers the makroXtens sensor arm extensometer is especially suitable for tensile tests on miniaturized specimens with special sensors for gauge lengths L0 of 5 mm or more.

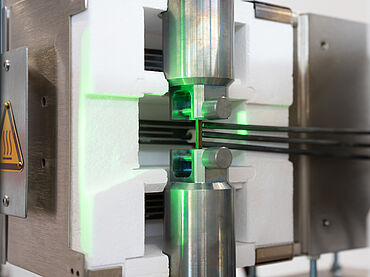

Tensile test on micro-specimens under high temperature

ZwickRoell offers a convincing product portfolio for the precise characterization of mini and micro specimen at high temperatures.

- With the laserXtens 1‑32 HP/TZ, mini specimens can be measured with maximum accuracy from a gauge length of 1.5 mm, at ambient temperatures and high-temperature up to +2,000 °C, in accuracy Class 0.5 to EN ISO 9513.

- High-temperature furnaces, especially those with short lengths and 1, 2 oder 3 heating zones, are ideal for testing mini and micro specimens, ensuring precise thermoregulation along the specimen.

- An alignment fixture and rigid load strings ensure optimal test conditions, as well as reliable and reproducible test results, even with the smallest specimens and under extreme temperature conditions.

- As an alternative to the laser extensometer the videoXtens 1‑32 HP/TZ, a non-contact camera-based measuring system, offers an ideal high-temperature option.

More information about our accessories for high-temperature testing

Optional: Automated mini tensile test

For especially reliable test results, the mini tensile test can also be automated. With the roboTest N testing system from ZwickRoell, a robot handles the specimen and precisely clamps the miniature specimen in the specimen grips. Operator influences such as hand temperature or hand moisture, as well as angled oder incorrect gripping of small specimen in specimen grips can be completely eliminated by the robot. A laser cross-section measuring device can also accurately determine the thickness and width of the miniature specimen, further increasing the reproducibility of the test results.

The use of automated testing systems not only increases efficiency but also significantly increases operator safety: The insertion of the specimen by the robot effectively protects laboratory personnel from injuries, such as trapping or crushing fingers, that can occur when clamping the specimen.

For better traceability and control of the test results, the specimen remains can be packaged in bags after the test. This ensures that test results can be easily and reliably assigned to any follow-up investigations.

Video to automated mini tensile test

This video shows the automated mini tensile test using the roboTest N. The use of the two AllroundLine testing machines increases the systems specimen throughput.

The longitudinal strain during the tensile test to ISO 6892-5, is measured optically using a specialized laser extensometer for short gauge lengths. The length measurement is transmitted live to our testXpert testing software.

Miniaturized tensile specimen - types and dimensions

ISO/TS 6892-5 specifies four different specimen shapes (type A to D) for miniaturized flat specimens. For round specimens three different specimen shapes (type P to R) are specified. Type D and P meet ISO 6892-1 requirements with regard to gauge length.

ASTM E8/E8M explicitly specifies in Annex A1 three different specimen shapes for miniaturized flat specimens. In addition, ASTM E8/E8M in Section 6 presents additional “subsize specimen” and “small-size specimen” round specimen for various metallic products such as sheet metal, heavy plate, pipes with large diameters.

Miniaturized flat specimens

| in mm (inch) | Gauge length L0 | Width in measurement range b | Length in parallel area of specimen Lc | Overall length L | Width in gripping range B |

|---|---|---|---|---|---|

| ISO/TS 6892-5 | |||||

| Type A | 5 | 1.25 | 7.5 | 23 | 4 |

| Type B | 10 | 2 | 12 | 32 | 6 |

| Type C | 10 | 2.5 | 15 | 35 | 6.5 |

| Type D* | 20.5 | 5 | 28 | 70 | 12 |

| ASTM E8/E8M “Annex A1” | |||||

| Miniature specimen 3 (6) | 2+0.1 (0.1+0.01) | 1±0.02 (0.04+0.001) | 2.6±0.1 (0.13±0.01) | 8 (0.3) | 4 (0.2) |

| Miniature specimen 2 (5) | 4+0.2 (0.16+0.01) | 1±0.02 (0.04+0.001) | 4.5±0.2 (0.17±0.01) | 15 (0.6) | 3 (0.1) |

| Miniature specimen 1 (4) | 8.5+0.5 (0.34+0.02) | 1.5±0.02 (0.06+0.001) | 10±0.2 (0.39±0.01) | 25 (1) | 4 (0.2) |

| ASTM E8 "Subsize specimen" | 25 (1.0) | 6 (0.25) | 32 (1.25) | 100 (4) | 10 (0.375) |

Miniaturized round specimen

| in mm (inch) | Gauge length L0 | Diameter in measurement range b | Length in parallel area of specimen Lc | Overall length L |

|---|---|---|---|---|

| ISO/TS 6892-5 | ||||

| Type P* | 15 | 3 | 18 | 32 |

| Type Q | 12.5 | 2.5 | 15 | 29 |

| Type R | 10.5 | 2 | 12 | 26 |

| ASTM E8 Small-size-specimen** | ||||

| Specimen 3 | 24±0.1 (1±0.005) | 6±0.1 (0.25±0.005) | 30 (1.25) | |

| Specimen 4 | 16±0.1 (0.64±0.005) | 4±0.1 (0.16±0.003) | 20 (0.75) | |

| Specimen 5 | 10±0.1 (0.45±0.005) | 2.5±0.1 (0.113±0.002) | 16 (0625) | |

| ASTM E8M Small-size-specimen*** | ||||

| Specimen 4 | 20±0.1 (0.8±0.005) | 4±0.1 (0.16±0.003) | 24 (1) | |

| Specimen 5 | 12.5±0.1 (0.565±0.005) | 2.5±0.1 (0.113±0.002) | 20 (0.75) | |

* meet the requirements of ISO 6892-1 with regard to gauge length

** proportional to standard specimens (L0 4x diameter)

*** proportional to standard specimens (L0 5x diameter)

ABOUT THE AUTHOR:

Dr. Harald Schmid

Global Industry Manager Metals | ZwickRoell GmbH & Co. KG

As Global Industry Manager, he is responsible for the industry strategy in the metals sector with a focus on market observation, further development of testing solutions and sales support in the international environment.

He has extensive experience in standardization work and is actively involved in various committees, including the international ISO committee ISO/TC 164 Mechanical Testing of Metals and national DIN working groups such as NA 062-01-42 AA Tensile and ductility testing for metals and NA 062-01-47 AA Impact test for metals and mechanical-technological testing of metallic pipes.

His academic career began with a degree in mechanical engineering (B.Sc. & M.Sc.) at the Karlsruhe Institute of Technology (KIT). After holding international positions in mechanical engineering, he worked as a research assistant at the Friedrich-Alexander-University Erlangen-Nuremberg with a focus on material characterization and sheet metal forming. He dedicated his doctorate to the topic of deep drawing processes with drawing beads.

Interesting customer projects using miniature specimen

- 50 - 100 kN

- +200 to +2000°C

- CF, LCF

- CCG, CFCG

- FCGR,TMF

- SSRT

- Creep

- Stress relax

- Tensile, compression, flexure