Testing of rubber and elastomers

Rubber and elastomers are indispensable in numerous industries – from the automotive industry to medical technology and everyday products. Precise materials testing is crucial for these materials to reliably perform their function.

The standard test methods, methodologies, and framework parameters for rubber and elastomer testing are defined in ISO standards and national standards such as ASTM, DIN, BS, NF and JIS. The tests focus on characterizing materials using standard specimens, as well as on measurements of components such as tires, dampers, conveyor belts, belts, seals and technical articles. They also include everyday products like rubber gloves or shoe soles.

The goal of physical testing is to ensure the quality and suitability of materials. This includes evaluating mechanical, thermal and chemical properties, as well as durability, strength, elasticity, hardness and resistance to wear and environmental influences.

Standards Tensile test Tear growth test Hardness testing Additional tests Automation Testing systems Interesting customer projects Request a consultation

Test method for rubber and elastomers

| Short description | Standards |

|---|---|

| Rubber & Elastomers | Tear growth test |

|

| Plastics | Elastomers | Tensile test |

|

| Rubber & Elastomers | Tear growth test |

|

| Plastics | Elastomers | Tensile test |

|

| Medical | Condoms | Tear strength / strain at tear |

|

| Medical | Medical examination gloves | Tensile test |

|

| Plastics | Hardness Ball Indentation & Rockwell |

|

| Plastics | Hardness Shore |

|

| Plastics | IRHD hardness |

|

Tensile tests on rubber and elastomers

Tensile tests are one of the most common tests. It is used to determine the force required to tear a rubber specimen by elongation. It provides several properties and is typically performed on dumbbells or ring specimens.

The most common testing methods for tensile tests on rubber and elastomers are described in ASTM D412, ISO 37 and DIN 53504.

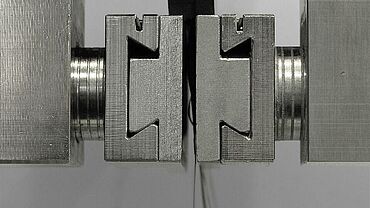

Tear growth tests on rubber and elastomers

This type of test characterizes the behavior of a notched, or damaged, material and is used to determine the tear strength or resistance of various specimens, such as trouser or strip specimens, angle specimens, crescent-shaped specimens, or Delft specimens. The tear growth test for rubber and elastomers is described in ASTM D624 and ISO 34.

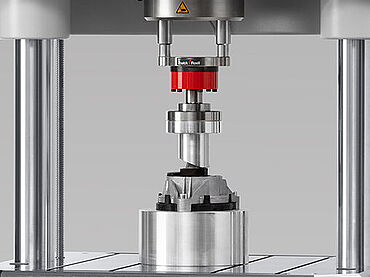

Hardness testing of rubber and elastomers

Rubber and elastomers are typically measured using the IRHD or Shore A method, and in specific cases, the Pusey & Jones method. Common methods for IRHD testing are described in ASTM D1415 and ISO 48-2. Test methods for determining indentation hardness using a durometer to measure Shore hardness are explained in ASTM D2240 and ISO 48-4.

Compression tests on rubber and elastomers

A compression test on rubber examines the material’s behavior under static compressive load. The goal is to characterize the mechanical properties of rubber and elastomers under applied compressive load.

According to ISO 7743, the specimen is subjected to four cyclic load cycles. During the fourth load, pressure modules are determined at specified reference points.

Measurement of residual compression deformation

The compression set test (DVR test) is crucial for seals. The loss of thickness is measured after a defined period of time under a specified deformation, potentially with simultaneous heat exposure.

The determination of the compression set is described in the following standards:

- DIN ISO 815-1 Determination of Compression Set - Part 1: At ambient or elevated temperatures

- DIN ISO 815-2 Determination of Compression Set - Part 2: At low temperatures

- ASTM D395 Standard Test Methods for Rubber Property—Compression Set

- ASTM D1229 Standard Test Method for Rubber Property—Compression Set at Low Temperatures

Shear tests on rubber and elastomers

Shear properties are typically measured using a double lap shearing through overlapping, and sometimes a “quadruple shear” method, which involves four rubber blocks to be sheared. The shear modulus is measured after several cyclic loads.

The "Determination of shear modulus and adhesion to rigid plates – quadruple shear method" is described in the ISO 1827 standard.

Rebound resilience

The objective of this test is to quickly and easily measure the elasticity of the material. One material that is up to 100% elastic stores supplied energy and releases it at the moment the force is no longer applied. In contrast, material that is up to 100% plastic absorbs supplied energy completely. These characteristics are used to measure rebound resilience.

The determination of rebound resilience is described in standards ISO 4662, DIN 53512 and ASTM D1054. ZwickRoell offers the right rebound resilience tester for this purpose.

Damper and bearing testing

Damping elements are frequently used in vehicle construction. They are made of elastomers and are often connected to metal mounts. Measurement of viscoelastic properties are done using servohydraulic testing machines across a wide range of frequencies and temperatures. Static testing machines are used to simulate maximum load and deformation conditions, or to reproduce specific operational scenarios in a laboratory.

Tire testing

The individual components of a tire, such as the rubber, textile underlay, tire cord and steel belt, are individually tested using conventional methods. The bond between the rubber and the metal or textile cords is crucial for a tire’s durability and quality. This property is determined through pull-out tests and adhesion tests. The driving conditions are tested on the complete tire. This can be done both statically, to measure tire deformation under complex loads, and dynamically, in a cyclical manner.

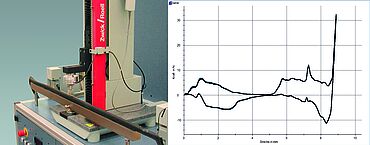

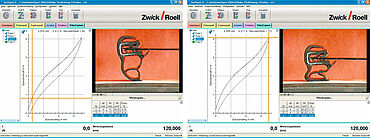

Tests on seals

Weather-stripping must reliably perform specific functions over an extended period. ZwickRoell provides the necessary standard test tools for this purpose and also manufactures specific tools tailored to each profile. For complex weather-stripping, understanding their deformation behavior under load can be crucial during development.

This is where ZwickRoell Video Capturing Plus comes in: A video sequence is recorded concurrently with the test using a webcam, camcorder, or the optical extensometer

videoXtens. Integrated hardware synchronization allows measurement data and video images to be precisely synchronized with each other. When the video is played, the corresponding measurement point is displayed in the curve graph.

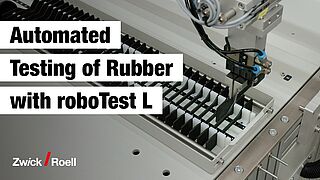

Automated rubber and elastomers tests

Tests on rubber and elastomers, such as tensile and tear growth tests, can also be automated, meaning they can be performed with fully automatic specimen feeding. An automated testing system is primarily used when many specimens need to be tested, or when operator influences must be eliminated. Hand temperature or moisture, as well as inaccurate or angled positioning of the specimen in the specimen grips, can affect the test results.

- The compact roboTest L robotic testing system can autonomously test up to 350 specimens. A thickness measuring device integrated into the system measures the specimen thickness accurately and consistently. The specimen gripper places the specimen in the testing machine and the tensile test according to ISO 37 / DIN 53504 is started automatically. After the test, separate disposal grippers remove the specimen remains from the specimen grips.

- The robotic testing system roboTest R is more complex and allows you to connect additional devices such as a specimen marking station, a centering station or a temperature chamber for accurate tempering of the specimen.

- To avoid operator influences even with small specimen series (type 1+2/S1+S2), ZwickRoell has the testing system ALEX in its portfolio: simple, compact, and cost-effective, it can be used with a series as small as 10 specimens.

Rubber or elastomers testing machines from ZwickRoell

Our testing machines for rubber and elastomer testing are designed for the special requirements in materials testing for rubber and elastomers and cover a wide range of mechanical tests:

- Electromechanical testing machines such as the zwickiLine, ProLine or AllroundLine for static applications are specially designed for tensile, compression and tear growth tests

- Electrodynamic testing machines such as the LTM are based on linear motor technology and can be used for DMA testing

- Servohydraulic testing machines consist of an extremely stiff load frame that is durable up to the nominal load. They have a fast and precise data acquisition, which is combined with an intelligent control of all load sequences. They are used to determine material properties under oscillating loads, such as the DMA test

- Temperature chambers for installation in static and dynamic testing machines enable tests to be performed in a wide standard temperature range from -70°C to +250°C. Heating is provided by electricity, while liquid nitrogen is used for cooling.

- Hardness testing machines measure the material hardness according to Shore and IRHD

- Rebound resilience testers for measuring the elasticity of the material

- Cutting presses for specimen preparation of dumbbells or ring specimens

- Automated testing system such as roboTest L, roboTest R or the testing system ALEX for the automatic testing of many specimens