Testing electrode coatings

Throughout the lifetime of lithium-ion batteries for electromobility applications, the bond strength between active material coatings and electrodes (Al or Cu foil), the hardness/stiffness/compressibility and the flexural strength of the active material coating and the coefficients of friction between cell layers are very important.

Bond strength of active material coatings and electrodes Video Hardness/stiffness/compressibility of active material coating Flexural strength of active material coating Coefficients of friction between cell layers

Test requirements

- In addition to the mechanical characteristic values, the bond strength of the single- or double-sided coatings on the arrester film is of great importance, since this connection is significant for internal conductivity of the battery. The bond strength also changes with the age of the battery and therefore it must be ensured that the connection is guaranteed for the long-term.

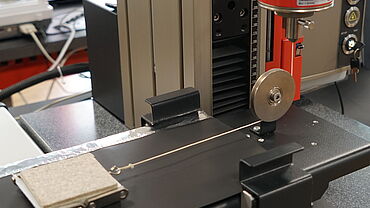

- The mechanical bond strength between active material and substrate can be determined differently: The easiest and therefore most common method is the peel test with a peel angle of 90° or 180°. For both variations, the coated film is applied to a carrier material (substrate) and is then pulled off by the testing machine at the specified peel angle. The methods are not standardized and are therefore very difficult to compare. The important qualitative assessment of the type of failure (cohesion or adhesion failure) is only possible to a limited extent with this method. Other disadvantages of this test is the large quantity of material use and time-consuming specimen preparation.

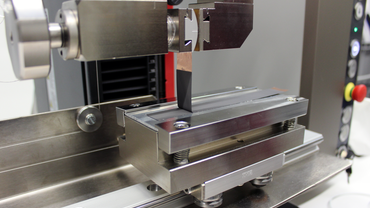

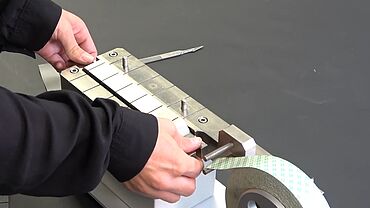

- A more reliable determination of the bond strength can be achieved by using a tensile bond Z-direction fixture. Here, five specimens are prepared simultaneously by means of a specimen fixture. The testing machine also automatically performs the defined parameters of contact pressure and duration identically for each specimen. After that, each individual specimen is pulled off in the Z direction and a clear maximum bond strength value is determined. In addition to very efficient specimen preparation and high repeat accuracy, this method also allows you to determine the cohesion and adhesion components of the fracture pattern.

Test requirements

- A major challenge in battery production is the coating process of the electrodes. For safe battery operation, excellent mechanical stability and predictable aging behavior of the active material must be ensured. An important test is the determination of mechanical properties such as coating hardness and coating stiffness.

- Knowing these parameters enables the optimization of coating processes and reveals the effects of different chemical components in the development and production process.

- To increase efficiency, it is essential that the usable width of the coating on the carrier material is as large and homogeneous as possible. By using instrumented hardness indentation methods, product-related quality variations in the coating edge areas can be detected and reduced.

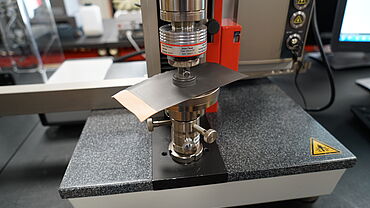

ZwickRoell testing solution

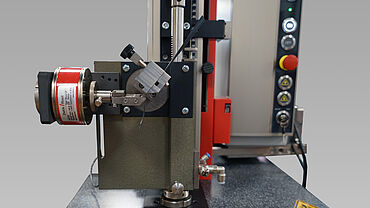

- The ZHN universal nanomechanical tester determines highly-accurate hardness values and elasticity moduli of materials and coatings. Different indenters enable adaptation to the respective coating characteristics. With the mapping function, mechanical properties deviating from the surface, e.g coating edge area, can be determined.

- The ZHU instrumented hardness measuring head enables quick and easy testing of mechanical properties of coatings. The ZHU can be quickly and flexibly installed in a materials testing machine and delivers highly accurate measurement results with its integrated load cell and digital displacement measurement system.

Test requirements

The active material of the electrodes is a 50 - 100 µm thick coating that can have greatly varying mechanical properties depending on the chemical composition and the selected production process. Knowing these is important for defining optimal settings of production parameters such as throughput speed, roller angles, and pre-load forces. Determining the flexural strength using a 2-point flexure test kit also enables the determination of the maximum permissible bending angle or radius at which the coating remains intact and the contact between the arrester film and the active material is maintained.

Test requirements

The determination of dynamic and static coefficients of friction supports a better understanding of the behavior of two touching cell layers in a dry production process. The friction between the film and the transport roller can also be determined in this way and it can be ensured that the set roller pressures, pre-loads, or roller speeds do not have a negative effect on the films and their surfaces.