Automotive Testing

The automotive industry is experiencing a major disruption – electrification is revolutionizing drive technologies and bringing with it new challenges in terms of safety, performance, and sustainability.

As a leading provider of mechanical and multifunctional materials and component tests, ZwickRoell supports manufacturers and suppliers in realizing innovative solutions. Our testing methods set standards for quality and efficiency by meeting the latest requirements for materials, structures, and drive components. Whether standard tests in accordance with international standards or customized testing concepts – with decades of experience and the highest level of expertise, we support you as you move forward into the future of mobility.

From high-strength steels and aluminum alloys for lightweight construction to tests for battery systems and electric drives, ZwickRoell is your reliable partner for materials and component testing in the era of new energy vehicles.

E-Mobility Chassis Body Engine & Drive Interior & Safety Automation Interesting customer projects Request a consultation

Electrification / E-mobility

Electromobility and electrification pose new challenges for the automotive industry – from the safety, performance, and service life of batteries to the efficiency of e-motors and multifunctional tests for fuel cells.

- Mechanical, electrical and thermal tests are crucial in battery testing in order to evaluate the load capacity, efficiency and safety of lithium-ion batteries under real conditions and to ensure the highest quality standards.

- Hairpin technologies and new types of electrical steel sheets optimize the performance and durability of e-motors, but also pose major challenges for production. Innovative testing methods are therefore extremely relevant in order to analyze precise material properties and manufacturing processes.

- At the same time, the development of fuel cells requires detailed material testing to ensure aspects such as gas diffusion and chemical resistance.

ZwickRoell uses state-of-the-art testing technology to support manufacturers and suppliers in reliably testing and further developing their products. Whether battery crash tests, dynamic material tests, or material data for high-precision simulations, ZwickRoell provides customized solutions for the mobility of tomorrow..

Chassis tests

The chassis of a vehicle is crucial for overall safety, driving stability, driving comfort, and fuel efficiency, and the shift to electromobility presents new challenges for testing.

- A key issue is the testing of large cast structural components (mega castings). These chassis die-cast parts significantly reduce the number of components in a vehicle, and thus also the complexity in production. New technologies allow thin wall thicknesses and a reduction of vehicle weight. Defects such as air pockets or cracks can occur during the solidification of these large components. Since these are structural components, they are subject to the highest safety standards, which makes comprehensive testing essential. The challenge in testing is that the components have very complex geometries, yet it is necessary to extract flat tensile specimens, which means only very small specimen geometries are possible. To perform this mini tensile test, ZwickRoell offers special short-clamping hydraulic grips for mini tensile specimens made from megacastings, which are up to the challenges of clamping and ensuring precise measurement. Flat tensile specimens are necessary because round specimens would have to be machined, resulting in the removal of the outer layer, which is crucial for evaluating the quality of the casting.

- In conjunction with shock absorbers, suspension springs act as damping elements between the chassis and body and are crucial for the ride comfort and driving safety of modern vehicles. The testing of springs and dampers is becoming increasingly important, especially for electric cars, in order to optimally adapt the driving behavior to the additional weight of battery systems. Coil springs are the preferred choice for automotive applications. The spring testing system from ZwickRoell is characterized by a unique multi-axial measuring platform with up to nine load cells, which record axial forces as well as transverse forces and lines of force with high precision and determine all spring characteristics – including penetration points, spring rate, block force and enveloping circle – automatically and in accordance with standards.

- In the automotive sector, wheels are made of steel, light metal, or composite materials and their tires. Tires are complex composite bodies composed of materials with various physical properties. ZwickRoell testing systems are used to determine the quasi-static and dynamic properties of wheels, rims, and tires. This ranges from standard tests on rubber, textiles, and wires to tests on the entire wheel/rim/tire system.

Body testing

To meet the increasing demands for occupant protection, lightweight construction and functionality, modern self-supporting vehicle bodies are becoming increasingly complex structures in hybrid construction. That is why, today, in addition to traditional steel grades, high-strength to ultra-high-strength steels, aluminum, and increasingly plastics are also being used.

Car body testing: Metal materials

Metals play a central role in automotive engineering – they ensure stability, safety, and durability and are easy to process. From high-strength steels and aluminum alloys for lightweight construction to complex cast and forged components, metallic materials have to withstand the highest loads.

- The basis for the evaluation and characterization are tensile tests on metals according to ISO 6892-1 or ASTM E8 with r-value and n-value determination. These tests are used to analyze the basic strength values of sheet metal.

- In addition, sheet metal forming test methods and the VDA 238-100 small plate bending test play an important role in modern car body construction in order to make the best possible use of the materials.

- In the event of an accident, extremely high strain rates occur, for example in the vehicle body. In order to precisely evaluate and optimize the safety and crash performance of the materials and components used, the behavior under these conditions must be known. The characteristic values required for this are provided by high-speed tensile tests on HTM series high-speed testing machines.

- In addition, the crack toughness KIc is a key parameter for assessing the fracture strength of metallic materials. It describes the resistance to crack growth and is determined in accordance with the ASTM E399 standard on a predefined cracked specimen.

ZwickRoell offers all the necessary testing methods for calibrating common material and failure models, thereby supporting the development of safe and high-performance vehicle structures.

Body testing: Polymer materials

Increasing lightweight construction requirements along with new requirements due to the electrification of vehicles are leading to a growing use of plastic parts in automotive engineering. This brings with it new challenges, as suitable material models must now also be developed for plastics for simulations, such as crash simulations.

In addition to traditional static plastic material characterizations, high-speed tests such as high-speed tensile tests and penetration tests are becoming increasingly important in order to examine the behavior of plastics under extreme conditions. In addition, fatigue tests on plastics are playing an increasingly important role in order to ensure the long-term resilience of plastics and their joints. CAMPUS (Computer Aided Material Preselection by Uniform Standards) is a network of material manufacturers that improves the comparability of test results through uniform testing standards, thereby also creating a foundation for the standardization of plastic fatigue testing in body construction. ZwickRoell is actively involved in this initiative and is therefore always up to date with the latest testing methods.

Engine & drive testing (combustion engines)

Mechanical material testing of engine and drive components is essential to ensure the reliability and performance of combustion engines and drivetrains. Components such as connecting rods, crankshafts, valve springs and clutches are subjected to high mechanical loads during operation and must therefore undergo rigorous testing. These tests include fatigue tests, hardness tests, and torsion tests, which help to ensure the service life and safety of the components. ZwickRoell offers standardized and customized testing solutions that meet the specific requirements of the automotive industry.

Tests on the Interior and Safety Components

From comfort testing on car seats to actuation tests on switches and buttons to force-displacement characteristics on solenoid valves or mechanical testing of airbag and seat belt systems – ZwickRoell offers precise testing solutions for the wide range of requirements in vehicle interiors. so that comfort, function and safety can be tested ready for series production.

Examples of testing on operational controls

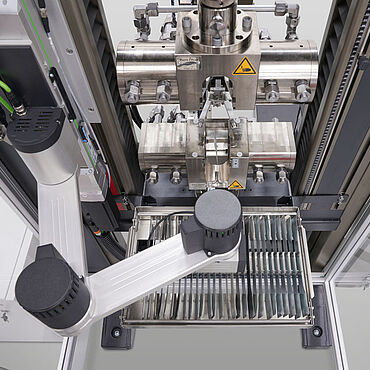

Automotive testing - Automation possibilities

Automated testing systems are an integral part of almost all areas and enable precise, reproducible results with reduced costs and greater flexibility.

By using the latest robot technology, tests can be performed around the clock, shortening throughput times and minimizing manual effort and thus operator influence on the test results. In the automotive environment, however, the number of tests is often not high enough to justify fully automated testing. With the testing system ALEX, ZwickRoell offers a high-precision, automated test platform for small test series that delivers accurate and comparable test results – reliably, efficiently, and optimally customized to your requirements.

ABOUT THE AUTHOR:

Head of Global Industry Management

- Responsible for the strategic development of testing solutions in the mobility and battery sector at ZwickRoell

- Specialist for mechanical materials and component testing in the automotive industry

- Several years of research experience at the Chair of Forming Technology and Foundry Engineering (utg) at the Technical University of Munich

- Directed numerous bilateral research projects with leading automotive manufacturers

- Scientific focus: Characterization of sheet metal materials and in-situ diffraction experiments

- 2023 Doctoral Thesis on the topic: Elastic-plastic characterization of high-strength steels