ISO 11608-5 Autoinjector Testing

The ISO 11608-5 standard specifies the requirements and test methods for automated functions in needle-based injection systems with automated functions (handheld autoinjectors).

Due to the specific area of application of injection systems worn on the body, the testing requirements differ from those for handheld autoinjectors. For this reason, the separate standard ISO 11608-6 was introduced, which specifies the requirements and test methods for needle-based injection systems for use on the body (on-body delivery systems (OBDS)).

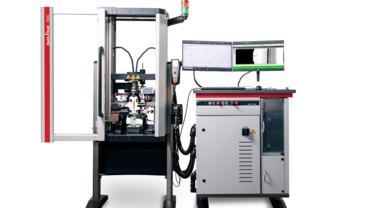

Below you will find an overview of the ISO 11680-5 test method and the autoinjector testing systems available from ZwickRoell. When dealing with large production batches, a testing process that saves time and resources is essential. Various automated ZwickRoell autoinjector testing systems are available for this purpose.

ISO 11608-5 objective Overview of tests to ISO 11608-5 Testing autoinjectors without medicationAutoinjector testing system Automated testing solutions Request a consultation

Objective of the autoinjector test to ISO 11608-5

An autoinjector is a medical instrument (medical device) with which liquid medication can be administered, and is therefore subject to strict quality controls. In the past, autoinjectors were mainly used when a drug needed to be administered as quickly as possible by medically untrained persons. Examples of this are adrenalin injectors used in cases of anaphylactic shock and morphine or atropine injectors used by soldiers in combat missions. Today there are two other factors that contribute to the increased use of autoinjectors.

One is injection vs. ingestion, meaning certain substances (for example, biopharmaceuticals) cannot be administered in tablet form, because they would be digested in the patient's gastrointestinal tract and would not enter the bloodstream. The other is that the autoinjector functions as an extension to the doctor's arm. Injectors guarantee a high level of application safety.

The correct injection and proper dose of medicine are vital to achieve the best therapeutic success. Therefore, pharmaceutical manufacturers strive to achieve a high level of automation in autoinjector technology. The patient simply removes the safety cap, positions the injector, and injects the drug by pressing a button. The subsequent injection process is completely automated. This means that all relevant injector functions must be checked before production batches are released to the market. This test is performed according to ISO 11608-5.

Overview of the tests required on autoinjectors in ISO 11608-5

ISO 11608-5 specifies the following tests on an autoinjector, which can be performed automatically using ZwickRoell autoinjector testing systems:

- Safety cap removal force in upward and downward direction

- Autoinjector activation force and travel

- Injection time measurement

- Determination of the administered drug volume, including the last drops with an integrated high-resolution scale

- Effective needle length for injection

- Safety function of the needle shield

- Testing of injectors with/without actuating button

- Color recognition on autoinjector/actuating button

- Acoustic recognition of start/end of injection

- Mistake-proofing through design (Poka-Yoke)

- Daily checks on load cell, scale, microphone, needle-length and fluid-presence sensors, as well as color recognition

- Measurement of ambient humidity and temperature

Advantages of the ZwickRoell autoinjector testing system

- Using the multifunctional autoinjector testing machine from ZwickRoell, all tests can be performed automatically on a single specimen without modifying test tools. This eliminates user influences and guarantees fast cycle times. The testing machine is suitable for autoinjectors with and without actuating button. Removal of injector caps in the upward and downward direction allows for tests that meet the latest standard requirements.

- The testing system can be expanded to accommodate additional tests, satisfying a variety of market requirements and product developments.

- Five different Daily Checks guarantee reliable test results.

- With an optional microphone to provide audible feedback, the system can detect autoinjector clicks, which indicate the start and end of the injection (audible feedback).

- Injection depth and injection time measurements with innovative, camera-based methods are achieved with the highest level of accuracy. In addition, an HD camera can be integrated to document liquid emission. You can save these images with the test results to support traceability.

- The machine can be optionally equipped with a monitoring mechanism that complies with requirements defined in the ISO 13849 standard. Our testXpert testing software manages the control and evaluation of these additional functions, as well as the entire test control sequence.

- When dealing with large production batches, testing processes that save time and resources are essential. Modular, flexible robot systems are available for fully automatic specimen feeding.

- The expanded ZwickRoell qualification documentation is suitable for validation support (DQ/IQ/OQ).

Test arrangement to ISO 11608-5 – product details

Testing autoinjectors without medication

Some of the medications used in autoinjectors are very expensive, which also makes functional testing with medication very costly. A cost-effective alternative is to test the mechanical function of the injector before filling it with medication.

In order to perform the test under realistic conditions, anelectromechanical servo actuator is also used in the testing machine. This simulates the counterforce of the medication cartridge, which normally acts on the autoinjector mechanism.

For the functional test, the autoinjector is positioned in the testing machine and started using our testXpert testing software. The test then runs fully automatically in the testing machine. The result is a measurement of the force or torque required to remove the safety cap, as well as the spring rate of the built-in drive unit. Monitoring and calculation of results are also performed in the testXpert testing software, which also offers a fully integrated FDA Part 11 option.

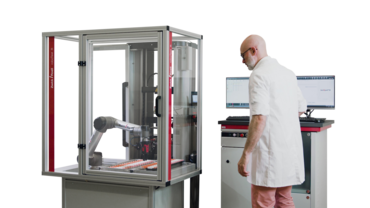

To achieve higher throughput rates, this system can be equipped with a lightweight roboTest N robot from ZwickRoell.

Discover your optimal testing solution for autoinjectors – we will provide comprehensive consultation!

Are you looking for precise, automated test procedures according to ISO 11608-5? Our experienced team will assist you in selecting suitable systems – whether semi- or fully automated. We will make your testing process efficient, reliable, and standards-compliant.

Automated testing of autoinjectors to ISO 11608-5

When dealing with large production batches, a testing process that saves time and resources is often important. ZwickRoell offers scalable automation solutions for the medical and pharmaceutical industry covering a wide range of applications.

roboTest N: automated autoinjector testing for simple applications

The testing assistant roboTest N supports the user with simple applications. Typically, the testing of 30 autoinjectors can be automated with one magazine filling. The system can be easily and flexibly adapted to changing test requirements without requiring any special programming knowledge.

roboTest R: fully automated autoinjector testing

The fully automated robotic testing system roboTest R performs the complete test sequence from removal of the cap, through testing of the autoinjectors, to disposal of the tested specimens and good/bad sorting. To ensure reliable and comparable test results, the measuring equipment is automatically verified on a daily basis (Daily Check). Due to using several autoinjector testing systems, even a large volume of specimens is processed quickly and reliably by roboTest R.

Traceable, tamper-proof test results in accordance with FDA 21 CFR Part 11

- Ever-increasing demands are placed on software used in the medical and pharmaceutical industries to document the traceability of completed actions.

- With the traceability option, testXpert III enables logging of all actions and changes before, during and after the test, making test results and the documentation traceable and protecting them from manipulation.

- Integrated user management and functions such as electronic records and electronic signature ensure that test results are always protected from tampering.

- Together with the organizational measures and procedure instructions that apply to the individual companies themselves, the requirements of FDA in 21 CFR Part 11 are fulfilled.

- ZwickRoell also offers a qualification service package (DQ/IQ/OQ) for validation support.

- testXpert III logs all test and system related actions and settings and can therefore always answer the question “When does who do what, why and who is responsible?”

Learn more about the testXpert III

Traceability option.