Testing Electrode Films

Electrode films for lithium-ion batteries are tested with tensile tests or puncture tests

Test requirement Test solution Video Testing systems Specimen preparation

Test requirements

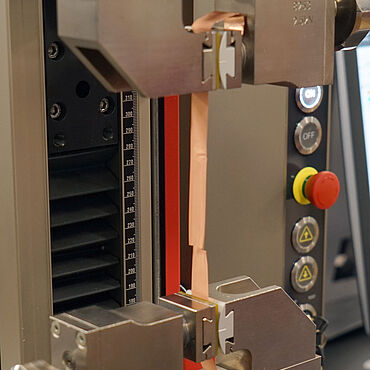

- Tensile tests are performed on all film-type materials of a battery cell. In particular, aluminum and copper films, polymer separators or protective film materials for pouch cells for example, are tested for tensile strength and elongation. Depending on their area of application, these films can have thicknesses of < 10µm and must be able to be reliably tested by materials testing machines with repeatability. Vertical alignment of the specimen, careful clamping and non-contact determination of extension via video or laser extensometer are all important factors to consider for precise determination of material properties. Special attention must be given to Lithium metal films, since their tensile strength can only be determined in an inert environment. These require special protective gas chambers, specimen preparation and specimen manipulation.

- The shells of pouch cells consist of a laminated layer composite. These are firmly welded together to ensure the structural stability and defined seal tightness requirements of the cell. For the sealed seam test, a tensile test is used to determine the maximum tensile forces.

- Separator films electrically isolate anodes and cathodes while allowing lithium ions to pass through. The separator must eliminate the possibility of a short circuit for the entire service life of the cell. The resistance of the film against specific defined indenters is determined using a puncture test.

ZwickRoell testing solution

- Based on the requirement, tests are performed with universal testing machines in a force range of 1 to 10 kN.

- Important material characteristics, especially in tensile testing, can be determined with repeatability due to easy alignment and adapted pneumatic grips. This also allows for very thin metallic and plastic films (<50µm) to be held without crushing or kinking.

- Very precise force and deformation sensors are used for the measurement of highly accurate material properties, which are mainly used in simulation processes. For the determination of strain values on very thin electrode films it is particularly important that there is no influence on the material characteristic values through sensor arm extensometers. Non-contact video- or laser-based extensometers of the videoXtens or laserXtens series are ideal for this purpose.

- Thermal influences can be freely simulated with a temperature chamber in a wide temperature range of -80°C to +250°C.