ZwickRoell – Your Partner in Materials Testing

We are a global leader in materials testing and your trusted partner for reliable test results. A fundamental requirement for reliable test results in materials and components testing is the perfect interaction among all testing machine components. For this reason we develop and manufacture both the load frames and all main components ourselves. Whether tensile test, compression test or flexure tests, function tests or standard tests, texture analysis or fatigue testing: with our product groups we offer testing solutions for test methods in R&D, as well as for quality assurance in more than 20 industries.

You can depend on custom-fit solutions and reliable test results.

For over 160 years. And into the future. Our more than 1800 employees make sure of it with competence, openness and passion.

Klaus Cierocki

Chief Executive Officer

Products in use

- Predominantly metals

- Up to 750 joules

- Charpy

- Izod

- Tensile impact

- Brugger

- Wedge impact

- 50 - 250 kN

- -80 to +2,000°C

- Creep

- Stress Relax

- SSRT, HE

- CCG

- Tensile

- Compression

- Flexure

- Universal

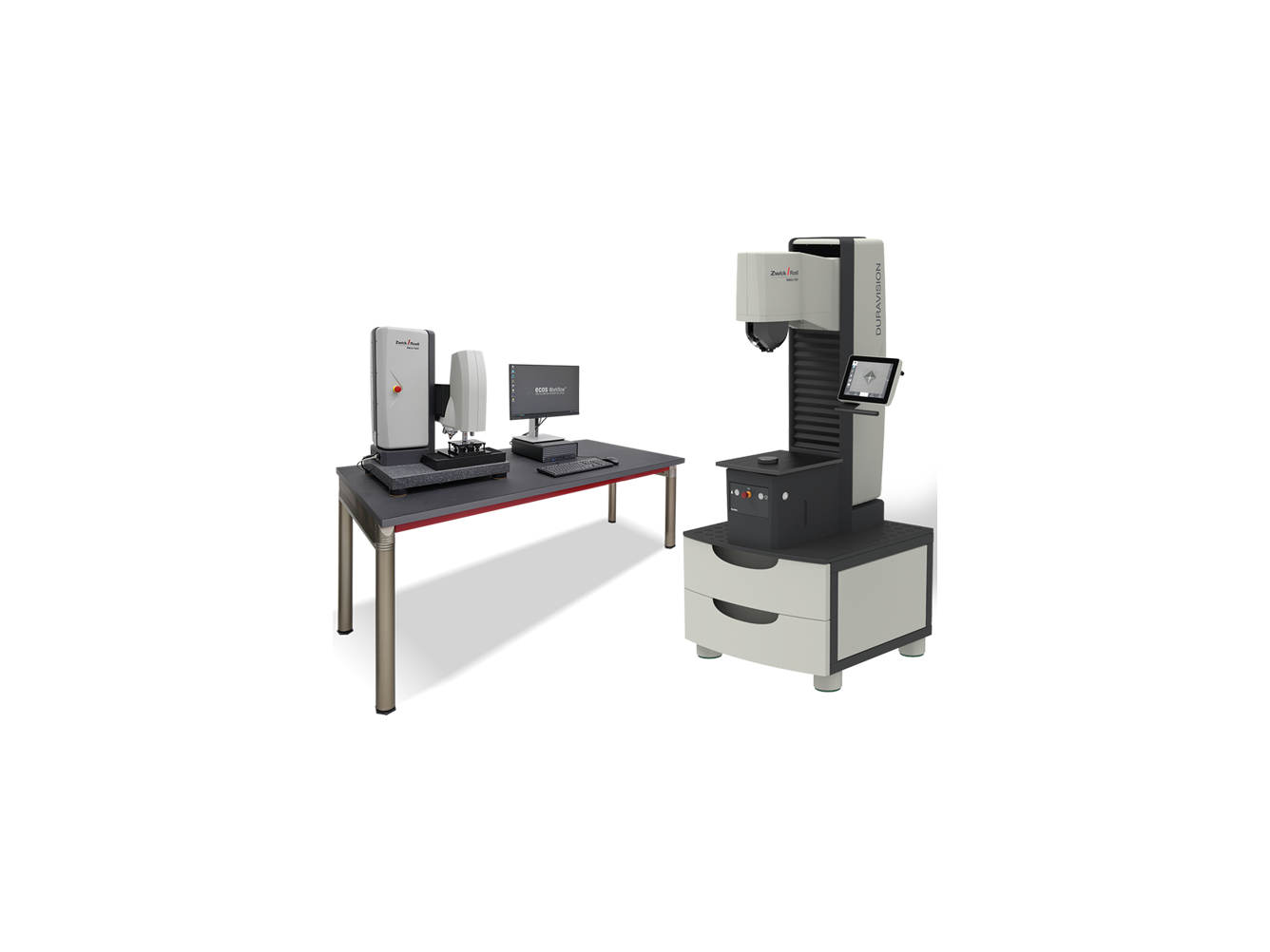

- 0.5 kN - 5 kN

- Tensile test

- Compression test

- Flexure test

- 160 mm

- Ambient temperature

- Up to 250°C

- Tensile, compression, flexure tests

- Cyclic tests

- Change in width measurement

- Strain distribution

- Test re-run

- 2D dot matrix

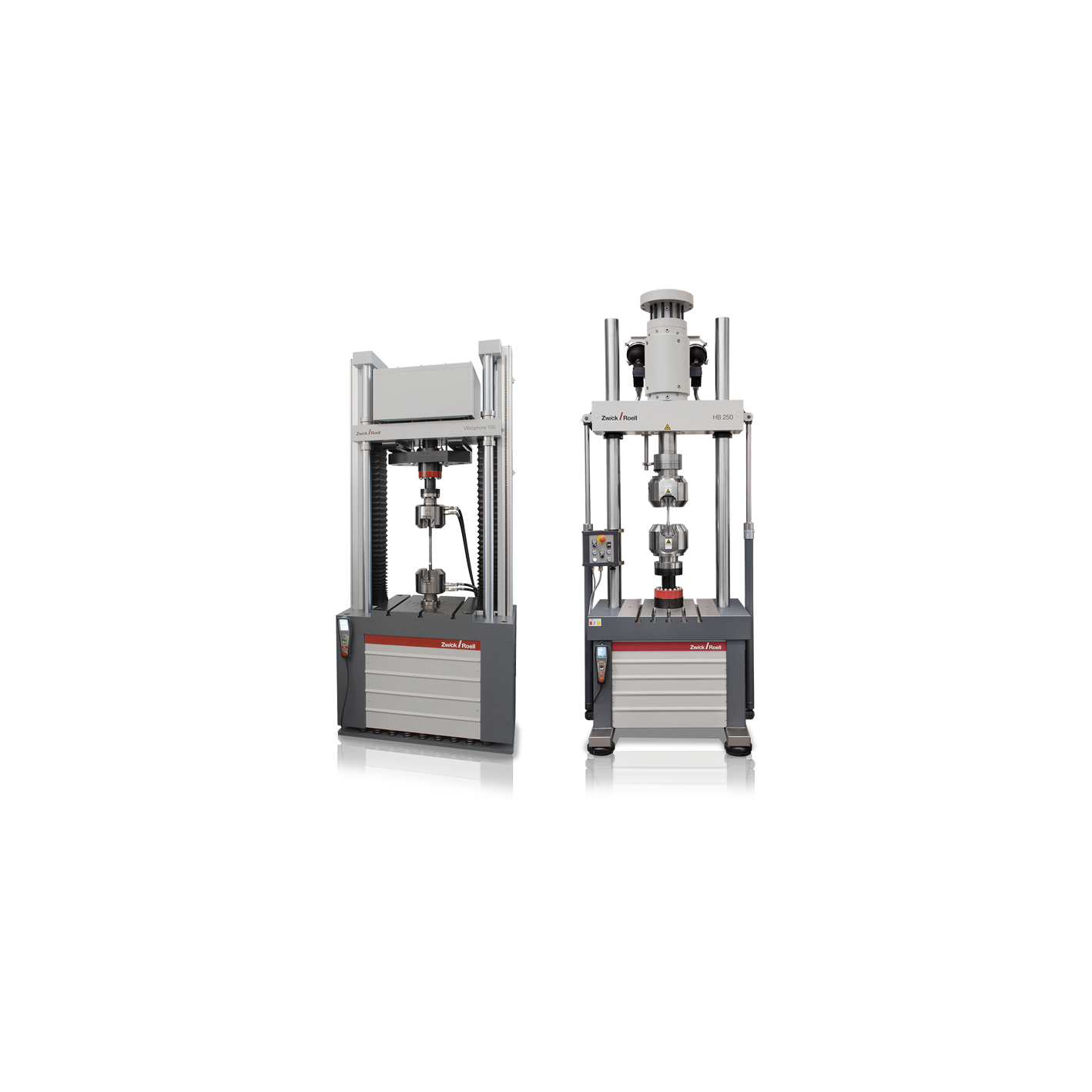

- 10 kN - 25 kN (HC)

- 50 kN - 500 kN (HA)

- 50 kN - 2,500 kN (HB)

- Fatigue

- Fracture mechanics

- LCF

- ISO 12106

- ASTM E606

- DIN 50100

- ASTM E399

- ASTM E647

- ASTM E466