Unique Solution for Testing Catheters Simulates Real-World Conditions

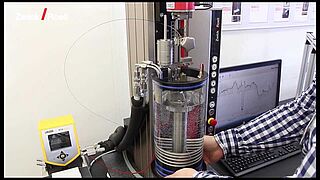

To simulate real-world conditions, major manufacturers of catheters often need to replicate a patient lying in an operating room and a surgeon inserting a catheter to test their products. In close cooperation with customers and surgeons, ZwickRoell developed a horizontal testing machine with a range of special adaptations to enable the simulated operational procedure on the patient. Over the years, ZwickRoell has expanded its portfolio to offer other testing solutions that address the design, testing, and production challenges faced by catheter manufacturers today.

From a horizontal Allround with or without water bath to a horizontal zwickiLine, ZwickRoell’s solutions can determine a wide variety of results such as

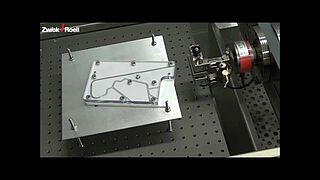

- Track force - measures the force needed to advance a catheter, interventional device or guide wire through a tortuous path

- Push efficiency - uses the proximal and distal load cell to measure the amount of force the distal tip of the product sees when a known force is being applied to the product on the proximal end

- Insertion force measurement - measures the force used to advance through the introducer sheath

- Guide-wire movement - measures the force needed to advance a guide wire though catheter, guide catheter or other interventional device

- Flexibility - measures the catheter tip’s ability to track over a specified bend in a guide wire, i.e. 90 degrees

- Guide-wire and catheter lubricity track measurement - comparative test using the track test data to determine if coatings affect the force required to advance product through a tortuous path

If you have further questions, please contact Jim Ritchey, Medical Industry Manager