Challenges in Automated Materials Testing: We are Your Partner in Every Industry

From aluminum and plastics, to metals and the medical industry, to testing writing instruments—many industries use automated testing machines to help simplify processes, obtain reproducible results in a short time, or to achieve high specimen throughput without unwanted influences. Here you can read about the challenges five ZwickRoell customers from different industries faced, how they successfully overcame them, and what considerations took place prior to the acquisition of their automated testing systems.

Plastics Aluminum Metals Medical Writing and drawing instruments Contact us

Challenges for the plastics industry

For our customer, a South American petrochemical company with production facilities in South and North America as well as in Europe, the challenge was to accommodate and harmonize the (testing) requirements of three continents in a uniform automated system and get reproducible measurement results across all. Since the company produces at worldwide locations and works and tests with different standards and test types (ASTM vs. ISO, Charpy vs. Izod), they always dealt with a certain level of inconsistency, as all locations also used different machines to perform the tests. In order to focus solely on the material—and test it in detail while eliminating influences of user and machine in advance—the customer opted for an automated solution from ZwickRoell.

Customer benefits

At all locations, where testing takes place, the company introduced the robotic testing system roboTest I. This system enables standardized pendulum impact tests and automates the tempering and specimen feeding processes, as well as impact tests according to Charpy or Izod. The plastic specimens are tested in a temperature range of -80 °C to +100 °C according to the Charpy, or optionally, the Izod method to determine their properties in a standard-compliant manner.

By unifying the equipment across all three locations, the company was able to achieve improved reproducibility of test results from all production sites: focus is now back on the material. Furthermore, the influences of user and machine were reduced, or completely eliminated.

Challenges for the aluminum industry

Our customer was looking for a solution that would allow them to test both flat specimens and pipe sections compactly, using an automated system. Furthermore, the goal was to obtain reproducible results, subject to different test standards, that would allow for reproducibility and uniformity of test results across various locations. These results, in turn, were to be accessible to all of the customer’s testing laboratories by means of a cloud-based solution. Another key factor for the customer was to eliminate unwanted influences from user and machine to the greatest extent possible.

Customer benefits

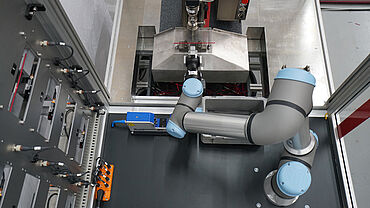

With the fully automated testing system roboTest L, we were able to provide an ideal, customized solution: the system allows the customer to run standardized metals and plastics tests, such as tensile, flexure and tear-growth tests, and supports throughput of up to 450 specimens. A bidirectional connection uploads the results to the cloud, which also transmits the specimen specifications.

By introducing automated testing, the company is now obtaining reproducible test results across their international production sites. On the one hand, the machine now determines the specimen cross-section during the test, and the data is processed and results are uploaded to the company cloud automatically—and their worldwide laboratory network has access to it. On the other hand, unwanted influences from user and machine were eliminated, returning full focus to the material to be tested. The ZwickRoell solution also supports reliable and secure documentation and statistical long-term monitoring.

Challenges for the metals industry

Our customer from the metal processing sector was looking for a solution to efficiently perform automated roughness tests on steel. These tests are important for further processing—for example for subsequent painting—in order to obtain valid results for the surface finish of the steel product.

Customer benefits

With the lightweight robot roboTest N, we were able to offer our customer a solution that was specifically tailored to their requirements for automated roughness testing. Our lightweight robot roboTest N is ideal for autonomous tests with up to 40 specimens in tensile or flexure tests, or in this case, for surface measurement. The feeding system is directly connected with the roughness measuring device. The system performs a double-sided roughness test on the top and bottom surfaces, which lasts approx. 30 seconds per measuring line.

In addition to the significant time savings resulting from automated tests, the customer can now count on reliable and traceable results, since unwanted influences from user and machine are reduced. Our customer’s quality testing has reached a new level and supports them in the production of more precise and high-quality products.

Challenges for the medical industry

Our customer from the medical industry was faced with the challenge of testing different autoinjector pens and syringes at various assembly stages in a standard-compliant and reproducible manner. And this with alternating tests and testing requirements, due to the company being located in different countries, including Germany and the United States. Within the scope of automation, it was important to our customer that updates could also be integrated at a later date and that the testing machine could be modularly expanded.

Customer benefits

To automate the function tests on autoinjectors, we were able to offer the customer an automatic testing system roboTest N as the ideal solution: the machine measures how far a needle extends, what amount of liquid is injected, or how high the force is that must be applied to actuate the injection. Since this function test generally takes 4-6 minutes, automation makes sense. Automation feeds the specimens to the machine and then removes them. The same machines were installed at the locations in Germany and the US. Implementing identical equipment creates test conditions for traceable and accurate results—across continents.

The automated testing solution lead to the following improvements: in addition to efficient and time-saving testing of the autoinjectors, the homogeneous testing equipment contributed to a standardization of the measuring principle. They were also able to achieve an increased number of tests, allowing users more independence, and without unwanted influences from the user or the machine.

Challenges for writing and drawing instruments

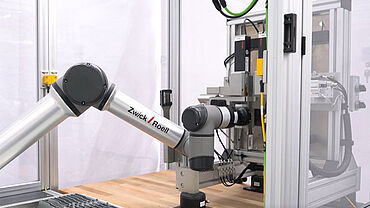

Our customer, a leading German manufacturer of writing and drawing instruments, planned to run automated 3-point bending tests on graphite lead, for which an automated testing system was retrofitted to their existing zwickiLine testing machine. In addition, a separator was connected, from which the robot removes individual lead specimens and transfers them to the testing machine for the test. Previously, the user performed this process manually.

Customer benefits

The customer now automatically runs the 3-point bending tests on graphite lead with the roboTest N testing system. After inserting the graphite lead into the separator, the robot arm removes a piece of lead and feeds it to a laser system that determines the lead diameter. It is then placed on the support and the tests starts automatically.

Commissioning of the system has since benefited our customer in many ways: next to efficient and accurate testing, a significantly shorter test sequence is now possible—with standardized, consistent quality and testing accuracy—including measurement of specimen diameters via laser. Influencing test variables, whether through the user or the machine were eliminated, shifting increased focus onto the specimens.

Learn more about automation.

Would you like to find out whether automation is worthwhile and possible to be implemented for your specific needs? Or how you can make your testing processes even more efficient through automation?

ZwickRoell offers a wide range of solutions, including the option to retrofit existing testing systems.

Our product experts are here to advise you.