Testing of Finished Textile Products

Everyday we encounter countless textile components such as straps on bags, buttons, or toys made of textiles. They are subject to constant loading and must fulfill certain quality characteristics to be able to meet safety criteria reliably (for example, buttons, straps, belt connectors). The reproduction of real-world conditions sometimes requires complex test arrangements, different specimen grips, and reliable results. ZwickRoell offers a wide-ranging product portfolio to cover a large variety of tasks.

Tensile Tests on Snaps to BS 4162

In the application shown above, the simple closing force of snaps and the pull-out strength of snaps are tested according to BS 4162.

The test arrangement used consists of 2 parts:

- Lower clamp

- and a type of gripper tong.

The snap with the textile fabric is inserted and secured in the lower clamp. A ring is pressed into the fabric and simultaneously the fabric is pulled tight. The upper part of the snap is manually pressed on. Then the upper part of the snap is clamped in the gripper tongs. No tensile force should be applied to the connection.

The tensile test is carried out to determine the maximum force of the push button connection. The results are shown in a typical force travel diagram.

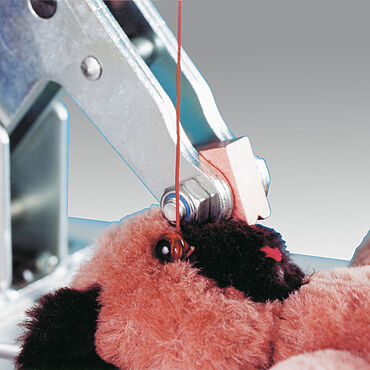

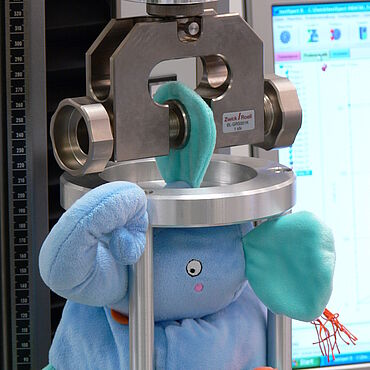

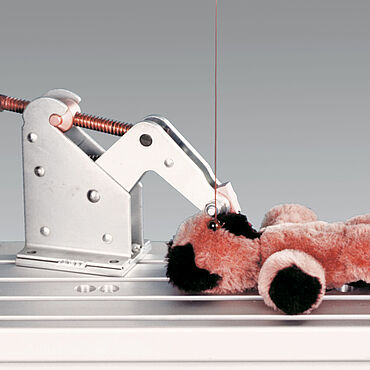

Tensile Tests on Stuffed Animals to EN 71

EN 71 defines requirements and methods for testing the mechanical and physical properties of toys.

In the above example, the limbs of stuffed animals are tested for their strength and seam connection. The toy is inserted into a device with a circular opening. The opening is designed so that the stuffed animal cannot be pulled through during the test. In this case, a simple screw specimen grip is used to hold the stuffed animal or the limbs.

ZwickRoell offers a wide range of diverse lower clamps, tools, and specimen grips for the various tasks.

Tensile Tests on Zippers to BS 3084

BS 3084 shows the different types of zippers and a variety of test options.

In the above example, a plastic zipper is tested to determine its properties. The textile part of the zipper is clamped so that the zipper is supported.

A tensile test is carried out perpendicular to the zipper and tested until the zipper fails. The maximum force is determined and the results are shown in a typical force travel diagram.

Tensile Test on Belt Connectors to DIN EN 1492

Belt connectors in the form of loops, knots or clips are tested for their safety-related properties.

In the example shown, the maximum force that affects the stitching, the safety clip, or the belt is determined. The belt is rolled in the roller grip and is held securely; on the opposite side the bracket is clamped in a pneumatic specimen grip.

The tensile test is carried out according to DIN EN 1492 to determine the maximum force of the entire connection.

A force travel diagram is recorded via the crosshead; an additional measuring system is not required. ZwickRoell offers a wide ranging product portfolio with diverse specimen grips and machine types to perform reproducible tests according to standards.