Make the most of a ZwickRoell Vibrophore

Equipment for the energy industry, for example. Petrochemical product storage tanks or reactor pressure vessel for nuclear power plants, require a very high degree of quality and reliability, to ensure safety and to avoid pollution to the environment. Therefore, comprehensive and wide-ranging research work is essential. As a member of the Institute of Nuclear Research Group, Institute of Applied Mechanics Brno (UAM) focuses on R&D activities to bridge fundamental research achievements and industrial applications for this industry. Apart from numerical simulations, experimental research is also a fundamental part of their research work.

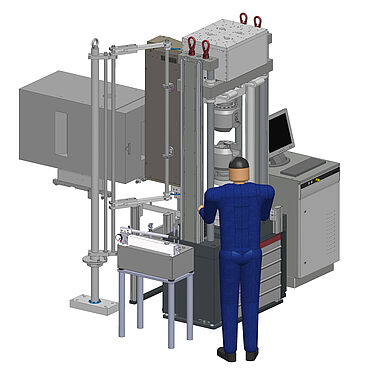

For such a research institute there is a strong desire for a testing system, which offers adaptability and flexibility to fulfill their wide-ranging research goals. To satisfy the customer’s diverse testing needs, ZwickRoell offered a Vibrophore 250 to UAM. Highlighted by "two-in-one" function, this Vibrophore 250 supports both dynamic and static tests through a variety of capabilities, including:

- HCF tests with standard flat/round specimens at room temperature;

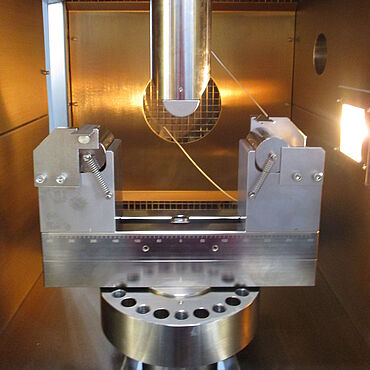

- Fracture mechanics investigation according to ASTM E399 and ASTM E 1820, for up to 350°C.

- Tensile tests according to ISO 6892-1, method A1 (Closed-Loop Strain Control);

- With ZwickRoell testXpert III *All-in-Suit* both customized static tests and standard tests are possible for up to 350 °C;

Configuration of the Vibrophore 250 includes:

- *Two-in-One* function with testXpert III *All-in-Suit*;

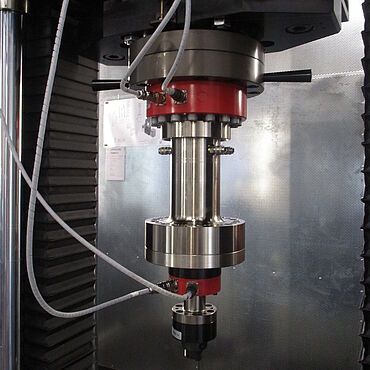

- MultiXtens for static tests, which has accuracy grade up to 0.5 to EN ISO 9513;

- Customized TEE for up to 350 °C, with the option to cool down to -80°C;

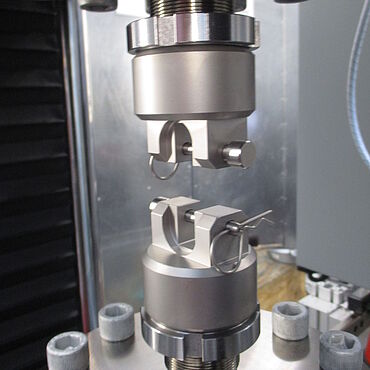

- Hydraulic wedge grips for standard round/flat specimens;

- Grips for CT specimens and SEB specimens;

- Additional 25kN load cell is also included for further potential of lower force range.

The Vibrophore product ranges from 25 kN up to 1000 kN, offering flexible choices for variable industries such as metal, automotive, aerospace etc. As electro-magnetic driving high frequency pulsator, Vibrophore has outstanding advantages. For instance:

- high testing frequencies enable high specimen-throughput for dynamic tests;

- resonance principle ensures minimal energy consumption (approx. 2% of the energy required by a servo-hydraulic testing system);

- *Two-in-One* function enables static tests;

Since the first generation of Vibrophore was released in 1945 we have delivered over 700 systems worldwide.