Siemens AG's saves time and space by using a two-area ZwickRoell materials testing machine to test materials for turbine blades

Acombination of scarce resources, climate change and increasing energyconsumption is posing global challenges for the energy sector.Gasturbines from Berlin-Moabit are high-tech products which are used in powerstation generators around the world. This Siemens AG plant has a long history;its employees nowadays are to be found engaged in engineering, production, intest centers and in service and support. To meet the challenges posed by adynamic market the gas turbine factory in Berlin has added a ZwickRoellmaterials testing machine to its testing equipment.

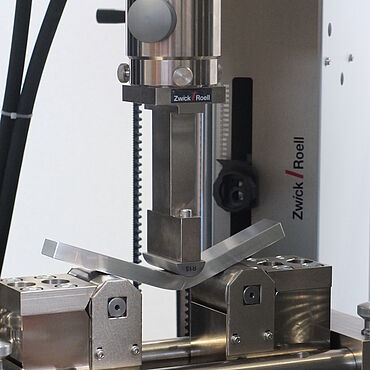

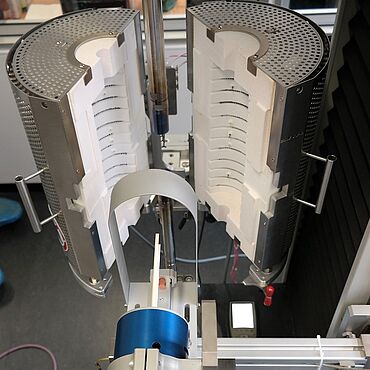

The Z250 SNS AllroundLine floor-standing testing machine with lateral test-area is used to test the materials used in turbine blades (Ni alloy). The main test area is occupied by tensile tests according to ISO 6892-1 (using hydraulic grips), together with technological bending tests according to DIN 50111 at room temperature. These flexure tests involve metallic materials with welded joints and a 3-point flexure test kit has been added to the materials testing machine for this purpose. The lateral test-area is equipped with a 3-zone round furnace for high-temperature tensile tests according to ISO 6892-2 on round specimens in a temperature range from 200°C to 1200°C.

For room-temperature strain measurement Siemens relies on makroXtens II HP - ZwickRoell's "all-purpose" extensometer. This contact-type extensometer records deformations on the specimen in accordance with EN ISO 9513 accuracy class 0.5 and transmits them to testControl II. Change-in-length measurement in high-temperature tensile tests is also performed with a contacting extensometer.

As well as enabling Siemens' Berlin gas turbine plant to avoid time-consuming reconfiguration operations, this AllroundLine testing solution eliminates tedious fixture changes and avoidable set-up costs. Moreover, the side test-area allows a wide range of applications with minimal space requirements. A further advantage of the materials testing machine is the ease with which the operating height can be adjusted to a convenient level.